Continuing with the occasional series of posts centred on light-role infantry, this one looks at the role of a small engineering plant.

Context and Requirements

As we have seen from the flood of imagery from Ukraine, the proliferation of UAS now means that direct and indirect fire will always be high risk, getting underground quickly is simply a matter of survivability.

As it has always been.

For many years now, long before the current conflict in Ukraine, the British Army has been reinvesting in skills for building field defences and looking at equipment options to improve force protection capability.

From infantry positions…

To artillery positions

Digging in is (hopefully) becoming the norm.

In this post, I want to focus on a narrow band of requirements, light-role infantry.

Light role infantry (and to some extent light cavalry) will tend to operate alongside support heavier support functions and vehicles or as part of a wider force, with more robust combat engineering capability.

That said, retaining and improving organic combat engineering capabilities (regardless of cap badge) should be seen in the same context as 81 mm mortars, a capability held at the Company level and directed by Company commanders.

Adding yet another equipment burden to light role forces takes them further away from their light role (perhaps they should all be motorised anyway) so this will have a cost in training, support, and capital. I would argue this is an essential investment that reflects the reality of contemporary operating environments, a need to get below ground at every opportunity.

Requirements might include the obvious ones of digging a trench or mortar pit, but there are other tasks.

Fill sandbags, drive pickets to secure a wire entanglement, destroy a small concrete barrier, cut, and move logs for overhead protection and unload an ammunition pallet.

Equipment will not completely replace hand tools, it might be used to get a head start, to quickly dig shell scrapes for an entire platoon at a halt which can then be improved for example. They certainly will not be used (nor can they) for heavier construction tasks.

To achieve transportability and supportability in combat service support light units, one must self-evidently make compromises on duty cycles, capacities and general robustness.

In framing the options, 500 kg and 2,000 kg are deliberate maximum weights for the two categories.

What can be towed by a quad bike (500 kg)

and

What can be towed by a Land Rover (2,000 kg)

Light role infantry will have a handful of quad bike all-terrain vehicles (ATVs) on hand, and potentially some Land Rovers.

They are already there, already in service.

Quad Bike Weight Class

The in-service quad bikes are relatively conventional and representative of the type commonly used in agriculture and other industries.

There are three options for further exploiting these versatile machines

Attach to the Quad Bike

This avoids the need to tow anything.

The image below shows an attachment called the XKV-TOR, but I understand that the manufacturer is no longer in business

There are a few others you can see online, but they seem either no longer available or home-made

Some manufacturers make direct attach loader kits for quad bike ATVs, but most are for farm implements, sprayers and sillage forks.

Whilst useful, the quad bike is not optimised and any equipment fitted to the front or rear will have a small breakout capacity and hinder other tasks.

Tow Behind Excavator

Tow behind excavators are not new

90 of them were purchased by the British Army in the mid-eighties from Powerfab.

The video below shows a Powerfab 125WT in use.

The video shows the equipment in use with a range of attachments, including an excavator bucket, earth auger and hydraulic breaker, also providing off-board hydraulic power for hand tools.

The Powerfab 125TW was powered by a 10hp engine, capable of digging to a depth of 2.6m.

Powerfab went out of business but is now back trading, although with a reduced product range, perhaps we could pay them to resurrect the 125TW?

Alternatives; the Kellfri Backhoe Digger also runs from a 10hp engine but does not have the hydraulic export feature of the Powerfab or quite the digging depth. As can also be seen, it does not have independent travel capability. At £3,600 each though, cheap, and at less than 500 kg, straightforward for the in-service quad bikes to tow.

The Rock Machinery Mini Excavator is another example of the breed.

The tow-behind excavators from Powerfab, Kellfri and others look good enough, simple, and extremely cheap.

Compact Standalone Machines

A couple of quad bike trailers were obtained from Logic several years ago, the SMT 171B and SMT 120B

Their 150 kg max payload is too small for any mechanical digging equipment and the stepped body design (to keep their width the same as the quad bike) means the width at the bottom is small, too small to carry any engineering plant.

Buying a larger trailer opens up the options, the Logic OXR for example.

This would enable a larger and self-contained piece of machinery to be towed by a quad bike.

The sub 500 kg excavator market is somewhat rarefied, but there are a couple worth looking at.

First is the 380 kg Komatsu PC01-1

Would you be able to keep the smile off the faces of onlookers?

Second, the Struck Magnatrac RS1000, despite its rather amusing appearance, is capable.

It can be fitted with rubber tracks, a rear ripper blade, several dozer blades, and even a backhoe kit with a digging depth of 2m.

One of these with a larger trailer would be at the upper limit for one of our quad bikes to tow.

Quad Bike Towable — Summary

Keeping weight down and dimensions small severely limits options, and one would have to seriously question whether any of these devices would be appropriate for light role forces. I have included them to show the possibilities, even though I do quite like the look of the Magnatrac RS1000.

Interestingly, in terms of weight and dimensions, those items described above could easily be carried as an internal load on a Chinook and Merlin, and a parachute air despatch platform.

They can be carried as an underslung load by all in-service helicopters, from Wildcat to Chinook. What they lack in duty cycle and capability, they certainly are not deficient in the portability stakes.

I can’t say I am a fan of the direct attachment approach.

The tow-behind devices look simple, easy to operate and cheap, but they take up a valuable towing hitch.

The larger trailer and standalone machine provide the same potential capability/capacity as the tow behind. When offloaded, the trailer can be used for other tasks whilst the machine is being operated, and you can not but be impressed by the Magnatrac.

It must also be noted that pilling up earth to form a berm/shell scrape with a small dozer blade like on the Magnatrac would produce fast temporary protection from shell fragments.

It could be further developed, but simply piling up an earth barrier in a few minutes would be better than digging a hole with an excavator to provide almost immediate interim protection.

Before reading on, would you mind if I brought this to your attention?

Think Defence is a hobby, a serious hobby, but a hobby nonetheless.

I want to avoid charging for content, but hosting fees, software subscriptions and other services add up, so to help me keep the show on the road, I ask that you support the site in any way you can. It is hugely appreciated.

Advertising

You might see Google adverts depending on where you are on the site, please click one if it interests you. I know they can be annoying, but they are the one thing that returns the most.

Make a Donation

Donations can be made at a third-party site called Ko_fi.

Think Defence Merch

Everything from a Brimstone sticker to a Bailey Bridge duvet cover, pop over to the Think Defence Merchandise Store at Red Bubble.

Some might be marked as ‘mature content’ because it is a firearm!

Affiliate Links

Amazon and the occasional product link might appear in the content, you know the drill, I get a small cut if you go on to make a purchase

Land Rover/Pickup Truck Weight Class

Moving up in weight to equipment that can be towed by or mounted on light vehicles like Land Rovers and pick-up trucks opens the choice up considerably.

One of the main drivers for the market is trailer and vehicle weights as allowed by UK road traffic regulations (with many similarities elsewhere). UK Maximum Authorised Mass (MAM) for a trailer is 3.5 tonnes on a normal (Class B) car licence (obtained after 1997), and that trailer must be no wider than 2.55m and no longer than 7m.

Restricting equipment to within these limits means it can be transported by personnel with standard driving licences, a considerable advantage, especially for light role forces. The commercial market is subject to these same pressures, and manufacturers have responded by developing equipment in the one to two tonnes range.

Attach to the Vehicle

Once popular, these have nowadays fallen out of favour as tracked mini excavators have matured, included here for completeness.

Standalone Machines — Trailers

Within the 3.5-tonne MAM is the weight of the trailer itself. Most plant trailers are about 1 tonne in weight. The actual towing capacity of any vehicle must also be defined and might be lower than 3.5 tonnes. Most pick-up style trucks, light commercials and Land Rover’s are usually rated at similar weights with a braked trailer.

Towing heavier equipment can be dangerous for the untrained, and many plant trailers tend to have two axles to reduce pintle weights.

The image below is the type of setup is common in the building and agricultural sectors, and there is no reason not to exploit this for defence purposes.

Several UK manufacturers of small plant trailers; tipping, beaver tail, ramped, two-axle, and three-axle. (The image below is a 2-tonne capacity three-axle beaver tail trailer from Nugent Trailers)

Adding a small hydraulic jib would allow them to be used for loading and unloading other stores and equipment when not carrying plant. This would add to the trailer weight, thus reducing carrying capacity, but it might be worth the added versatility.

It might also allow spare buckets and other attachments to be carried.

Taking this approach means that any equipment selected would be in the 1-to-1.5-tonne range, but it also means the utility of the trailer is increased as it can be used for other things once the vehicle has been offloaded.

Tracked Excavators

The JCB 801.8 Excavator Towed Ultralight (as shown in the image below) is already in service, with a suitable trailer, but only in small quantities, 18 at the time of order.

Although a few years old, the 801.8 is typical of the type, with a maximum dig depth of 2.4m and a range of buckets and attachments such as augers and hammers.

Each of those shown in the image below would be a useful addition.

An open cab with folding rollover protection is also available, and this might be attractive as it would allow them to be carried as an internal load on Chinook and Merlin.

They can be used to excavate the complete hole break up the ground or disrupt roots and rocks such that hand digging can be completed much more easily.

These are versatile machines, but of course, there are plenty of others on the market, almost every manufacturer of engineering plant has a mini digger range.

They will range in size and weight but all the manufacturers generally start from an operating weight of 1 tonne upwards, with some having slightly different digging depths, bucket capacities and breakout forces (a measure of power exerted at the bucket tip).

Some will have conventional tails, others zero tails, and many manufacturers are now offering electric variants (Bobcat E10 shown below, making a nice mouse hole in an urban combat environment!)

Most will also have a small chassis attached dozer blade.

Stand on Skid Steer

Most conventional skid steer or tracked loaders tend to be too heavy to tow with a standard 1-tonne trailer, so the industry has responded by creating stand-on versions to reduce weight. Ditch Witch, Bobcat, Sherpa, Wacker Neuson, and Vermeer, all have a range of models.

This type of machine is mostly not designed for digging or earthmoving. They are typically used as a tool carrier and for loading and unloading pallets or granular materials, in this context, their low height and weight make them a useful addition to the discussion.

Articulated Wheeled Loaders

As with the stand-on tracked loaders, articulated wheeled loaders are a growing market with an increasing variety of manufacturers (Wacker Nuesson shown below)

They are also available in weight ranges, open or enclosed cabs, and retrofit track kits.

Beyond the major construction equipment manufacturers, less well-known brands continue to thrive in this sector; Avant, Multi One, Sherpa and Norcar.

Each one exists in a range of weights that includes the 1-2-tonne bracket.

They are unlikely to be digging a mortar pit with them but are included for wider application.

Before reading on, would you mind if I brought this to your attention?

Think Defence is a hobby, a serious hobby, but a hobby nonetheless.

I want to avoid charging for content, but hosting fees, software subscriptions and other services add up, so to help me keep the show on the road, I ask that you support the site in any way you can. It is hugely appreciated.

Advertising

You might see Google adverts depending on where you are on the site, please click one if it interests you. I know they can be annoying, but they are the one thing that returns the most.

Make a Donation

Donations can be made at a third-party site called Ko_fi.

Think Defence Merch

Everything from a Brimstone sticker to a Bailey Bridge duvet cover, pop over to the Think Defence Merchandise Store at Red Bubble.

Some might be marked as ‘mature content’ because it is a firearm!

Affiliate Links

Amazon and the occasional product link might appear in the content, you know the drill, I get a small cut if you go on to make a purchase

Compact Dozers

There are a few sub-5-tonne dozers on the market, but very few I can find at less than 2 tonnes

Again, our friends at the Struck Corporation in the USA have an option, the petrol MH4900 and diesel MH8500 are similar models, and they can be equipped with several attachments such as a 6-point dozer or backhoe.

This is an extremely versatile and capable machine.

In the USA, there is also a niche market that manufacturers have responded to, developing walking and mountain bike trails.

Sutter Equipment offers the Sutter 300, a sit-on dozer designed specifically for trail construction tasks.

Although very narrow in function, they are certainly suitable for that role

Another interesting machine for the trail construction sector is the Single Track ST-240, which has a front-mounted dozer blade, and a front-mounted backhoe (if that is a thing)

It also has a remote-control kit, which is a safety positive.

They could be easily carried on the same type of trailer shown above, although the arm is shorter than conventional excavators due to the tasks it is designed for, that might be a compromise worth taking for the general performance.

Another interesting machine from over the pond

Attachments

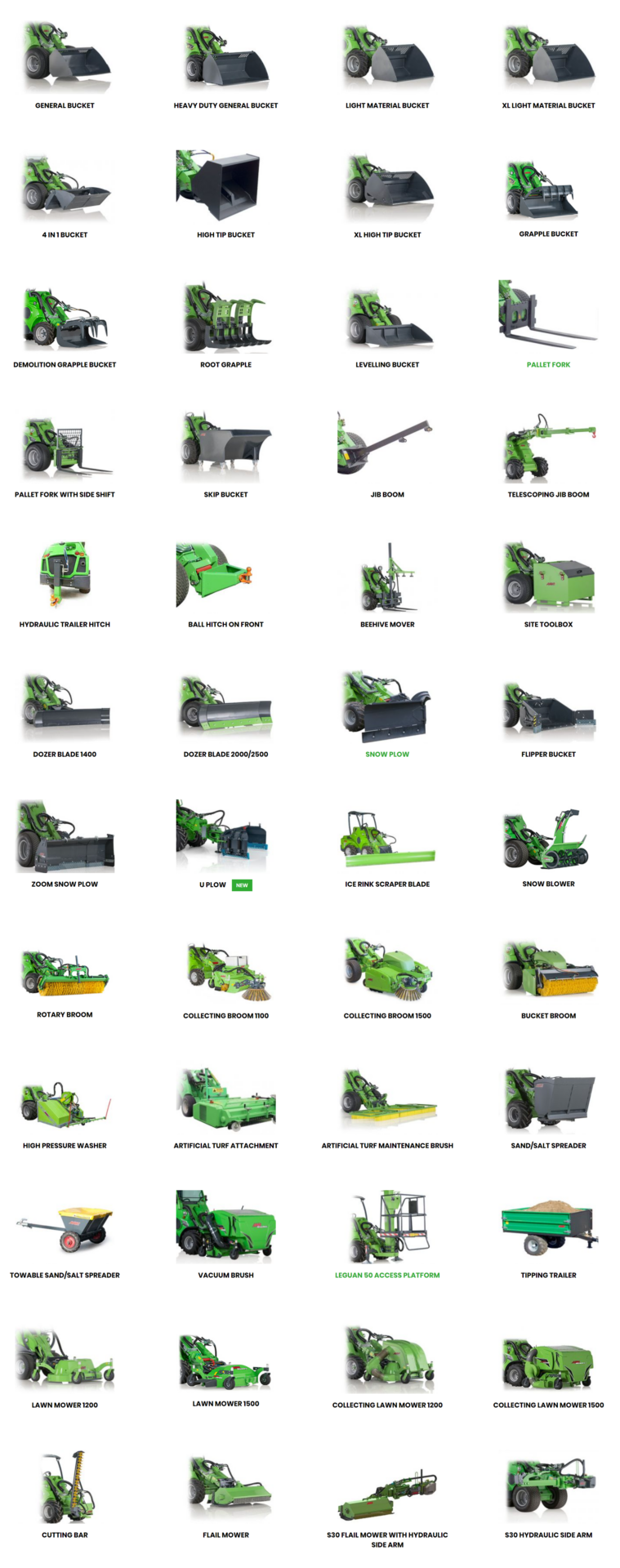

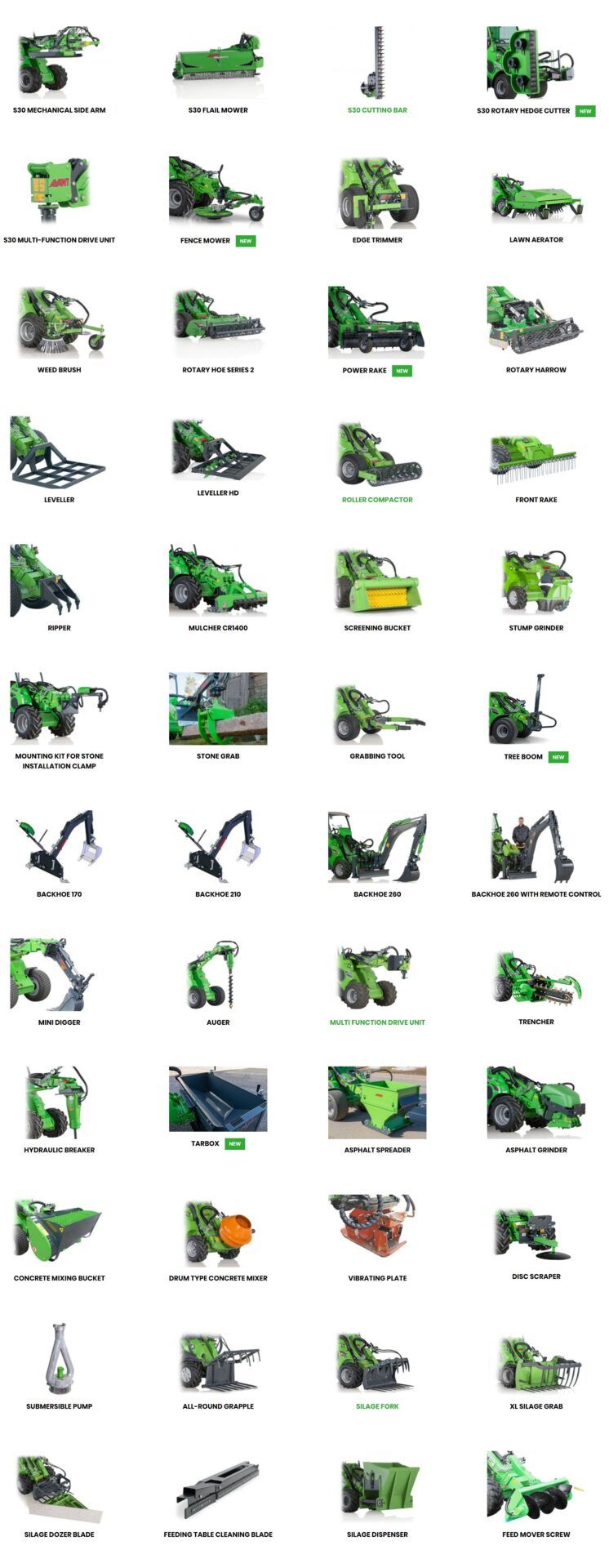

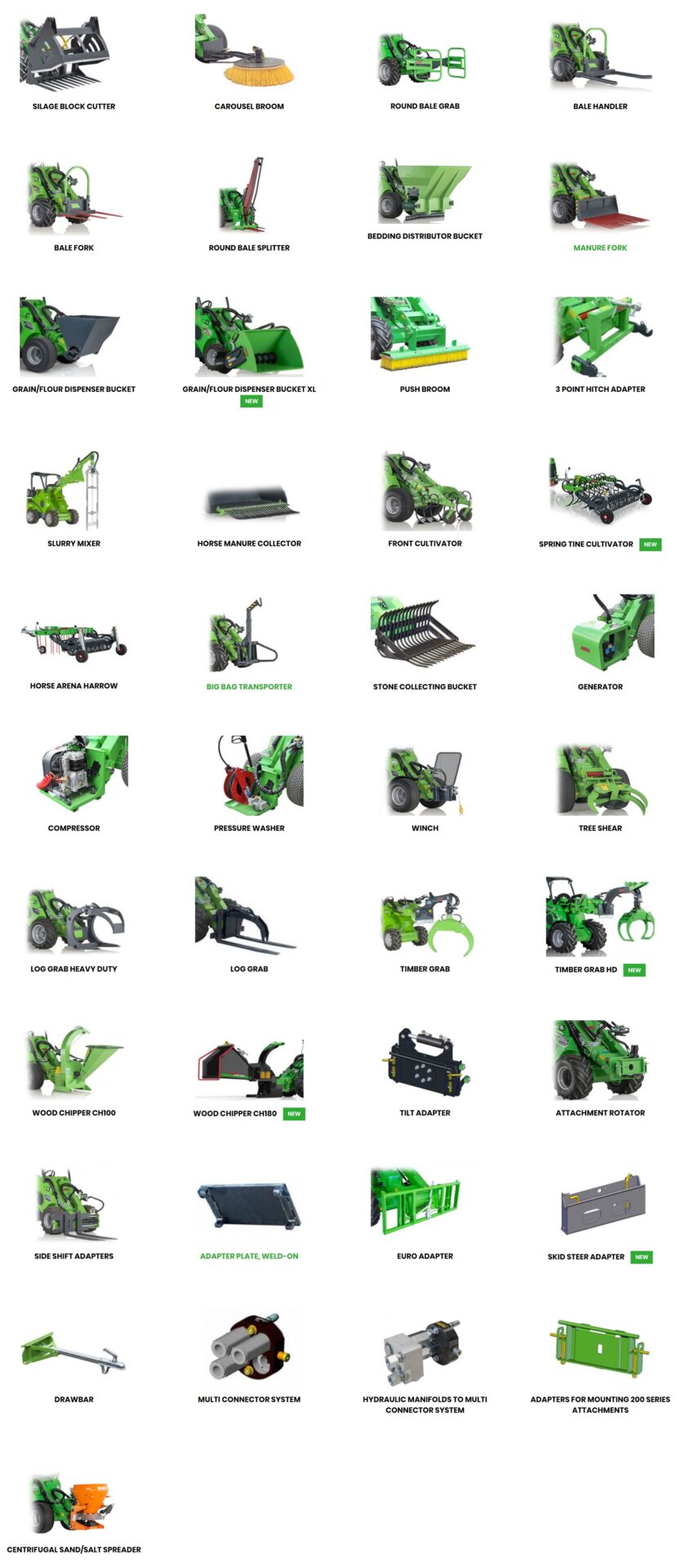

Auxiliary flow capacities are an important performance metric for these machines, as they often dictate the types of attachments that can be used. Whilst a bucket and blade will be used for most tasks, attachments can dramatically improve versatility. The image below from Multi One shows just one example of the range of attachments available in this sector.

A stone collecting bucket and artificial grass attachment might not be useful but a timber grab, tree shear, post driver and auger may be. Winches, compressors, generators and hydraulic power packs might also be useful, especially the latter, for powering hand tools such as chainsaws, breakers and cutting equipment.

Here are a few examples…

Clearing an indoor area for a temporary command post

Unloading a NATO ammunition pallet and moving it to a distribution point or mortar position

Digging the same mortar pit

Digging a hole for explosives to make a tank barrier

Driving a picket or earth anchor to secure a wire entanglement

Destroying a concrete barrier or creating an access hole

Cutting trees for trench overhead protection

Moving the trees to the trench that doesn’t have any overhead protection

Filling sandbags and continuous tube bags

These are versatile machines.

Final Thoughts

The tools below are cheap, require minimal training, and have no support contracts or REME personnel to maintain them.

When looking at additional equipment for light role forces, they are the competition.

This means any additional equipment has to earn its keep and be supportable, else it will get left behind and be a massive waste of time and money (both in short supply). We have to ask, can the simple tasks of digging holes and moving earth be improved to such a degree that it is worth adding support and deployability burdens to light role forces?

The British Army is small, so every time I do these kinds of posts where the sweet shop is open, it is with that in mind

Can we maximise efficiency through technology, and increase the workload or throughput of every soldier in a unit?

These small machines are not high capacity, won’t be as tough as their larger family members, and won’t always be the answer.

But my thinking is that often, hydraulics beats mandraulics, and if we can do things slightly quicker and leave soldiers less fatigued, we should be serious about looking at the options.

I believe that yes, we can do that, and we can do that without a massive investment in time or money. Each of these machines is off the shelf, all that is needed is some green paint, as the saying goes.

Move into the 3-6 tonnes weight range and a whole host of engineering plant becomes available, much more familiar and commonplace such as crawler tractors, backhoes, and skid steer loaders. If we are concerned with transportability, we need to limit our thinking to what can be towed by a quad bike or pickup truck type vehicle and within towing limits of standard drivers licences.

In addition, they can each be carried inside a Merlin or Chinook, or as an underslung load. Most will also be liftable by whatever wins the New Medium Helicopter competition.

They are not going to win any wars, and yes, some of them look like novelty toys. But would it be that difficult or financially burdensome to buy a handful of these and give them a run-out, at least to test the concept?

Discover more from Think Defence

Subscribe to get the latest posts sent to your email.

Fantastic! Fascinating article, filled with common sense, as per usual….

Now we just need some Iveco Daily’s to tow this stuff around, and maybe a few Brimstone….

Glad to see you got around to this. Mini loaders are incredibly versatile machines. Ride-on machines can be used to tow trailers as shown – imagine the engineers carrying the backpacks of all the troops.

This article could do with a little maths:

A mini excavator has a 50L bucket and would typically manage 2 buckets per minute. Ergo it shifts 6 cubic metres per hour.

A man would shift about 0.5 cubic meters per hour (over the course of a day). Thus a mini excavator does the work of 12 men and doesn't fatigue the one man which operates it.

There is a reason we don't dig holes manually in commercial operations.

Suggest that the main lesson from Ukraine is that this digging capacity probably needs to be remotely operated too.

Thank you very much for mentioning Powerfab in your article. We are now offering an updated towable excavator powered with electric lithium-ion batteries which is quiet (stealth) we also offer a remote operator station so the operator can be safely away from hazardous situations. With live 360 degree video streaming, VR and fast 5G connection our operator can control the excavator in real-time! It also has 3 DOF haptic feedback which mimics the movement of the equipment you control so the operator feels better immersion, which could also work for drones! Please come along to Swansea for a live demonstration. https://www.facebook.com/powerfabltd/