The most enduring military logistics challenge is producing and distributing clean, drinkable water.

It cannot be dehydrated, it cannot be compressed, it cannot be flat packed, and there are no clever tricks to avoid the simple fact that water, when consumed, is the same as water everywhere else (stand fast you seawater folks!)

The water demand will vary depending on the weather, physical exertion rates, and whether it will be used for drinking or cooking, washing, equipment cooling, or medical reasons. Armies have developed various techniques and strategies that combine the usage of boreholes, purification from bulk sources like rivers and lakes, storage, and distribution.

Once purified, water distribution uses a series of increasingly smaller packages, from water tankers to water bottles, and everything in between.

Advances in materials technology have resulted in more sophisticated filtration media, allowing much-improved systems to emerge with a high degree of predictability, safety, and efficiency. But as good as these modern systems are, they still need a source of bulk water.

Atmospheric Water Generation

Atmospheric water generation (AWG) is a technique that draws water from the atmosphere using one of two techniques, absorption or cooling. The first uses desiccant materials to absorb moisture that is then extracted, usually over a day-night cycle, where differences in humidity and temperature can be exploited.

The second technique typically involves cooling to enable the collection of condensed water, this cooling requires a power source.

The technology is not new, Watergen has had deployable and vehicle-based systems available for nearly a decade, others more recently.

The 70 kg Watergen GEN-35V military unit can produce 35 litres daily, at 25 °C and 55% RH. It is a self-contained unit, only requiring a power source.

An older video below also provides additional information.

I think Watergen may be focusing on civilian applications, but other providers are available, with some taking OEM units from Watergen. The French Army is equipping some of their VBCI vehicles with Watergen units, with Cofely-INEO as the integrator.

Other providers include Genaq, Hogen Systems, Uravu, Akvo, AWG and Drupps, all with alternatives and differing scales, including this containerised solution from Rayagua.

Nothing is free, of course, powering a device requires fuel or renewables, renewables are not always that practical for deployed and mobile military forces, and fuel, like water, has to be stored and distributed. However, reading through the various marketing claims they all seem to focus on a best-case of 1 litre of fuel for 5 litres of water, so worthwhile looking at.

One interesting approach is for vehicle technical water, cooling, windscreen and sensor washing. This approach dispenses with the need to purify and maintain drinking quality.

The US Defense Advanced Research Projects Agency (DARPA) has recently launched a research programme called Atmospheric Water Extraction (AWE) to develop technology that can extract water from arid air. AWE focuses on additive manufacturing and material technology to create a usable system in two forms; a single person (called the expeditionary track) and for a group of approximately 150 people (called the stabilization track).

The key difference between the DARPA programme and those described above is the target to extract water from arid air using advanced ‘sorbents materials’.

To demonstrate the challenge, this article in the Science magazine a few years ago described a technique using a Metal-Organic Framework (MOF)-801 that was tested in Arizona. It produced 100g of water using 1.2 kg of the material in a full day/night cycle using sunlight and ambient cooling.

As can be appreciated, generating enough water for 150 people.

More from DARPA is below.

University of California (Berkley) have an interesting video on Metal-Organic Framework materials.

At the end of last year, General Electric was awarded a $14.3m contract to contribute to the AWE programme, joining Physical Sciences, Honeywell, the Massachusetts Institute of Technology, and the University of Texas.

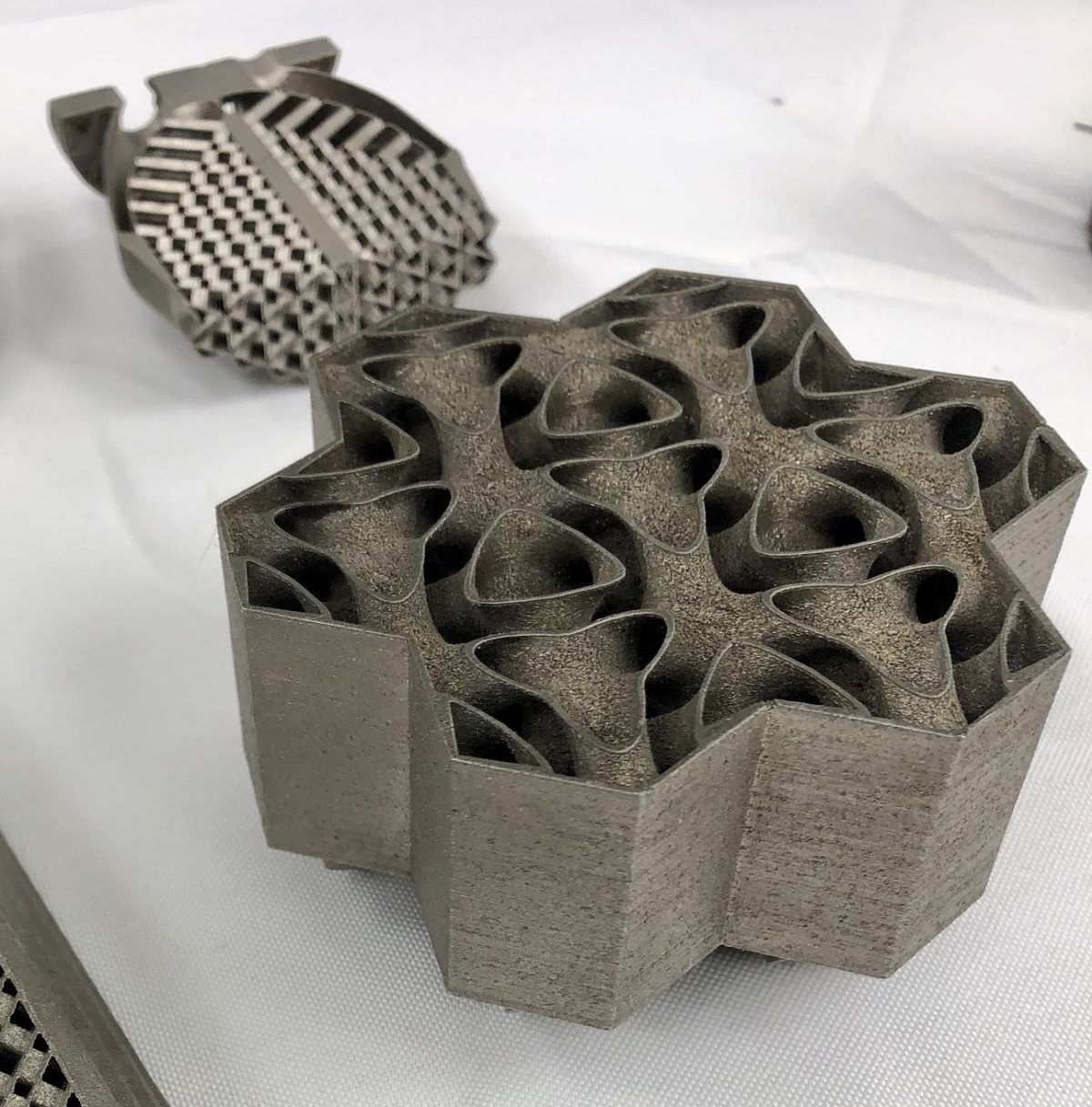

The material is formed into a 3D-printed heat exchanger.

The ever-present challenge for UK defence is whether to wait for research programmes like those from DARPA to bear fruit, or purchase off-the-shelf systems and accept their limitations in arid conditions.

I expect we might have already trialled or deployed some systems above in limited quantities.

Will extracting water from thin air gain more prominence in the equipment programme?

Read more…

Discover more from Think Defence

Subscribe to get the latest posts sent to your email.

Interesting! Thank you. Got to fill up those BVs from somewhere!

Some way off yet, but imagine the logistic chain (particularly the most inefficient last mile bit – presumably larger bases will still use wells) that could be reduced if every vehicle supplied it’s crew with water…

You’d imagine they would have utility onboard ships, where fresh water is limited, and resupply expensive and at times dangerous.

If 1 litre of fuel for 5 litres of water is the best case then is it really an option worth looking at? A 30,000Ltr water tanker could do around 100km/30Ltr diesel… ish. That same 30,000 Ltr of water generated by condensers would need best case 6000Ltr of fuel. All of which would need to be moved and stored.

In arid conditions the air is also dry so the fuel consumption will of course increase as vast amounts of air will need to be past through the condenser. A solar powered version would be interesting but hardly discreet. As you mentioned it may not be practical. The water from condensers would not be instantly potable and would need further treatment too.

Some interesting developments there but I don’t think any of it can match a tanker full of water or a water purification unit. Improved water purification units and waste water recycling methods could be a better fit for isolated locations in arid conditions.

Given the impetus to switch to U*Vs, how much longer will there be a requirement to sustain numerous water-drinkers (humans) in theatre?

One of the by-products of a hydrogen fuel cell is water ….

Condensed water and generally water taken from the air is almost minerals-free. AFAIK you need to add minerals if you want to drink much such water over weeks.