The Supacat All Terrain Mobility Platform (ATMP) is just about exactly that, designed to carry heavy loads over extreme terrain. An extremely versatile vehicle, the latest variant has an advanced electric drivetrain.

Supacat ATMP History

During the 1982 Falklands Conflict, the majority of available helicopter lift was used for 105 mm Light Gun ammunition and Rapier battery generator fuel because the British Army had no suitable vehicle that could negotiate the soft terrain.

Although some CVR(T) and Volvo BV202 Snow Cat vehicles were embarked, they were very few and generally used for moving troops forward or engaging Argentine forces, not providing logistics support.

Immediately after the conflict, a requirement was defined to close that gap, especially for a vehicle that could both carry and tow more than a Snow Cat but be lighter and more compact, better suited to expeditionary and airborne operations.

Meanwhile, Supacat had designed a built a vehicle for agricultural use, intended for mounting and carrying spraying equipment to hard-to-reach locations.

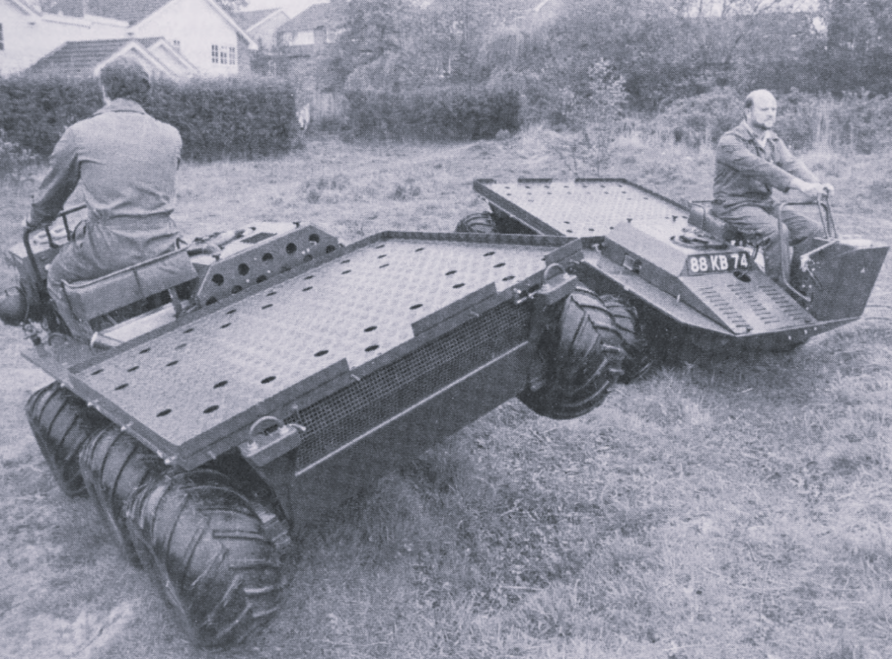

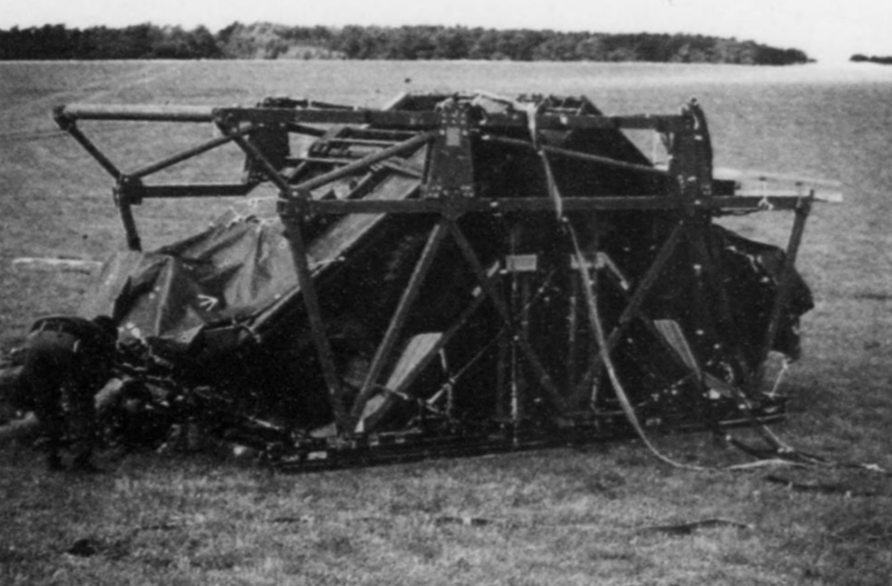

The image below shows the prototype Supacat vehicle under trial.

In 1983, the MoD sponsored a set of trials on the Isle of Jura to further develop the requirement. Vehicles included the BV202, a Land Rover with low-pressure tyres, and the Supacat 6×6 vehicle in its Mk I guise.

A further set of trials were arranged at Lydd Ranges in 1983, the Supacat vehicle impressed, and 7 were purchased by the MoD for use on ranges with large intertidal areas, each with an enclosed cab.

Further work on the requirements resulted in an open-top vehicle with a pair of stowable ramps and a winch that could be used to haul pallets onboard.

This was the Mk 1, shown below.

More research with 5 Airborne Brigade resulted in the Mk 2.

The MoD formally created a revised requirement called the All-Terrain Mobility Platform (ATMP), the Mk 2 Supacat vehicle competing with twenty other designs, including the Rasant Berktrak mower-derived Rolba Goblin and Land Rover derived Esarco 6×6 shown below

Although the Robla Goblin would enter service for a different requirement (EOD equipment carriage), the Supacat vehicle won and the ATMP name stuck.

Thirty-six Mk II’s entered British Army service in 1988, following trials the year earlier, and the two trials vehicles were also converted to production status.

Supacat designed the vehicle but was unable to manufacture it in quantity, so entered into production-sharing contracts and in 1984, the production vehicles were manufactured by Williams Fairey Engineering Limited (of bridge fame).

Some were tested on the Falkland Islands, confirming their suitability in an environment that generated the requirement in the first place.

ATMP were used by the British Army during the 1991 Gulf War, with some being converted as Rapier missile towing vehicles, and for RAF airfield operations.

Following the conflict, twenty ATMP were quickly reverted to the standard configuration, and a crane was added and deployed with Royal Marines to Northern Iraq supporting the Kurdish minorities, OP HAVEN. The C130 stacking pallet and forklift handling proved to be very useful, and the low ground pressure reportedly allowed it to be driven into a minefield to recover an injured soldier.

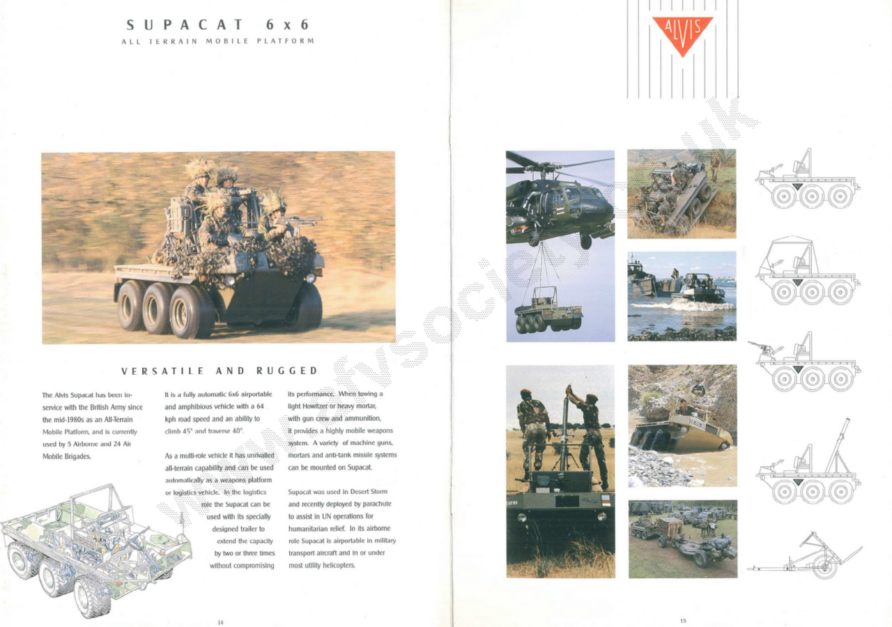

In 1995, an agreement was made between Alvis (now BAE Systems) and Supacat in which Supacat would retain design and production rights for civilian markets, but Alvis would be responsible for military markets.

An additional order for 86 ATMP and 84 SLLPT trailers was let for approximately £4 million in 1996.

Operation AGRICOLA was the name given to the UK contribution to KFOR, UK forces were responsible for securing a route to Priština from Macedonia. This route included the crucial Kacanik Defile, a narrow gorge with a series of bridges and tunnels.

5th Airborne Brigade consisted of elements of 1 and 3 PARA, reinforced with the 1st Battalion, The Royal Gurkha Rifles. In addition to 657/659 Squadron AAC Lynx helicopters, the main lift was supplied by eight RAF Chinook and five Puma helicopters.

ATMP were included in the main lift and were used to establish radio rebroadcast locations, among many other tasks.

An ATMP was used in the recovery operation at the Pentagon after the 9/11 attacks.

In the early 2000s, most of the ATMP vehicles were disposed of and in the run-up to operations in Iraq, many of them were repurchased from the civilian market, and pressed back into service.

Yes, this really happened.

The Parachute Regiment used their ATMP in 2003, Operation TELIC (great article here)

In 2005, Supacat regained sole marketing rights.

In Afghanistan, ATMP were used to support C-IED efforts, Apache Attack Helicopter refuelling points and in their traditional logistics role. Due to years of neglect, a lack of investment, insufficient spares holdings and questions over continued support for a non-Euro compliant engine, they were withdrawn in 2001. 2010.

Reliability in the hot weather of Afghanistan was poor, the availability of 50% of the deployed fleet on any given day was considered to be good.

The cost of spares was proving to be high and taking up valuable space on the air bridge.

An environment mitigation package was considered before withdrawing the vehicles, but it was assessed as being equivalent to a complete redesign and therefore, a new acquisition. Supacat informed the MoD that, given their workload at the time with Jackal, it would be unable to deliver such a redesigned vehicle for two years.

The MoD then considered further options for the Land Force’s Load-carrying Platform capability, and it was judged that a quad bike and trailer did not have the payload to fulfil the role.

Several manufacturers were asked to ‘express an interest’ including…

Roush (Balter 2)

Development Engineering and Enterprise Limited (WVL-C6-AS)

Enhanced Protection Systems UK Limited (Tomcar TN5)

John Deere, Yamaha Corporation, Honda Motor Company Limited and JC Bamford Excavators Limited declined to bid.

In April 2009, Enhanced Protection System was awarded the contract for 78 Springer vehicles at a total cost of £3 million, although other sources have that figure at £7 million.

A Tomcar magazine article stated;

The company’s Business Development Director, John Stoddart, who had just returned from a specialist training area in the Southwest where he had been involved in a driver instructor programme. As a former soldier with 35 years under his belt, first as an infantryman and then commissioned REME, who served out the closing years of his armed forces career in Defence Procurement, there can be few better qualified than Stoddart to carry out this urgent operational requirement through from drawing board to frontline deployment

In what was an interesting turn of phrase, Dr Andrew Tyler (Chief Operating Officer for the MoD’s Defence Equipment & Support) stated;

The Springer dune buggy will be an added capability for the troops

The article went on to state;

EPS, which is primarily known for its supply of ballistic protection to the UK MoD but is also a key supplier in the UAV scene had doubled its workforce to cope and subcontracted out some of the work. In its current configuration Springer is fitted with a 1400cc Lombardini diesel engine although larger options are available.

Taking a quote from the MoD’s website

Lack of armour is a benefit. Armour would be paid for with impaired versatility. In any case, Springer’s main purpose is to carry casualties and cargo between relatively safe helipads and base facilities.

Driver training was established at Leconfield and in Germany.

The delivery of 29 Springer vehicles into Afghanistan started in July 2009 and ended with the last batch, consisting of 2 Springer vehicles, received in Afghanistan in July 2010.

Transportation of the Springer vehicles, to and from Afghanistan, was via land and sea. The balance of the fleet was used for training and development purposes.

In September 2009, the Sun reported problems with the Springer fleet that had emerged during initial driver training.

And to add to Mr Brown’s woes, fears have been raised over a £7million fleet of off-road Army vehicles set to be flown to Afghanistan next month. A military source said that despite being passed fit for use, there had been “real problems” with steering during testing of the Springer vehicle. The concern over the 40mph Springer buggies came during tests at the Defence School of Transport at Leconfield, Yorks. Seventy of the two-seater buggies have been bought to help transport casualties between helipads and bases.

One tester of the Springer said the vehicle needed bigger rear tyres and more power. And a senior military source told The Sun the teething problems were worrying.

He said: “We have a real problem with the Springer. This is meant to be a tough go-anywhere vehicle capable of high speed over rugged ground. To have steering columns damaged by a few bad bumps in Yorkshire is of some considerable concern.”

The MoD denied any problems, of course with an MoD spokesman telling the newspaper;

There have been no reports of problems with the vehicle. Springer has successfully passed its trials with the Army, has been declared fit for purpose and is going into service

The deployment continued.

Jane’s also described a Springer 2 revision, retrofitted to existing vehicles as a result of operational experience but these would not solve the fundamental problems.

Springer was removed from service in March 2011, recovered from Afghanistan and declared out of service by September 2011.

All 78 vehicles were sold to civilian users for about £7-10k each and for the rest of operations in Afghanistan, quads and trailers were used, despite the MoD judging they were unsuitable, the very reason for the Springer acquisition was initiated.

A rare UOR failure

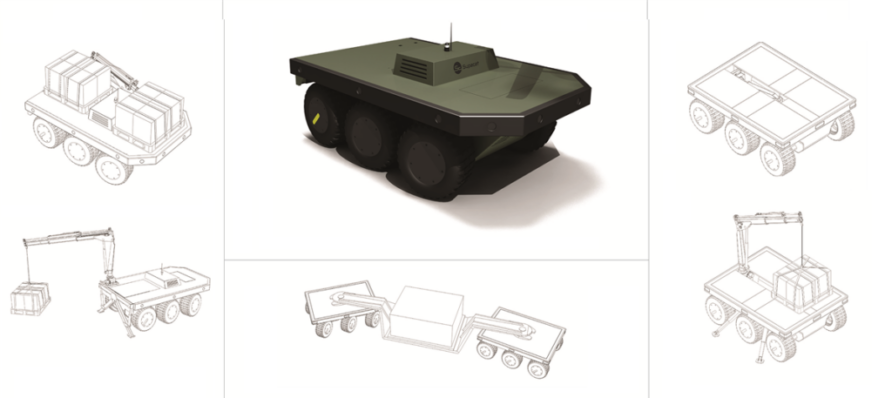

At the Land Forces 2014 exhibition in Australia, Supacat showed off its concept for a new and improved Supacat, the Mk IV.

Commenting on the updated design, Michael Halloran, MD of Supacat Pty Ltd, the Australian subsidiary of Supacat, said:

When we looked around the market, we found that there is nothing that combines the payload, mobility and robustness of the ATMP, so in developing this concept vehicle we decided to look at maintaining the fundamental strengths of the platform while updating the human interface and the automotive and communication systems.

At the Royal Navy’s Unmanned Warrior 16 exercise, an ATMP MkIII was used to support the QinetiQ team.

Subsequently, the MoD issued a tender requirement for a range of support services for the maritime autonomous trials team (MASTT).

In 2018, Supacat announced it would collaborate with the University of Exeter on a modernisation programme that would both address obsolescence issues and also develop a hybrid drivetrain.

The video below discusses the hybrid ATMP development

Development of the H-ATMP continued, and an optionally unmanned variant was shown at DSEi 2019.

The ‘optionally manned’ demonstrator utilises a terrain detection and response system for enhanced mobility and optimised endurance. An object categorisation and response system for obstacle clearance or avoidance during technical off-road driving, which can be tailored to the capabilities of the vehicle, driver or a remote operator, and a path planning and motion behaviour system using simultaneous localisation and mapping (SLAM) for the navigation of lead and follow on vehicles.

This programme culminated in a demonstration of eATMP

ATMP continues to be in demand in the specialist civilian sector, examples include pole carriers and even an all-terrain drilling rig from Structural Soils Ltd.

Export customers included Malaysia, Canada, and Brazil.

Before reading on, would you mind if I brought this to your attention?

Think Defence is a hobby, a serious hobby, but a hobby nonetheless.

I want to avoid charging for content, but hosting fees, software subscriptions and other services add up, so to help me keep the show on the road, I ask that you support the site in any way you can. It is hugely appreciated.

Advertising

You might see Google adverts depending on where you are on the site, please click one if it interests you. I know they can be annoying, but they are the one thing that returns the most.

Make a Donation

Donations can be made at a third-party site called Ko_fi.

Think Defence Merch

Everything from a Brimstone sticker to a Bailey Bridge duvet cover, pop over to the Think Defence Merchandise Store at Red Bubble.

Some might be marked as ‘mature content’ because it is a firearm!

Affiliate Links

Amazon and the occasional product link might appear in the content, you know the drill, I get a small cut if you go on to make a purchase

ATMP Capabilities

Dimensions and Automotive Capabilities

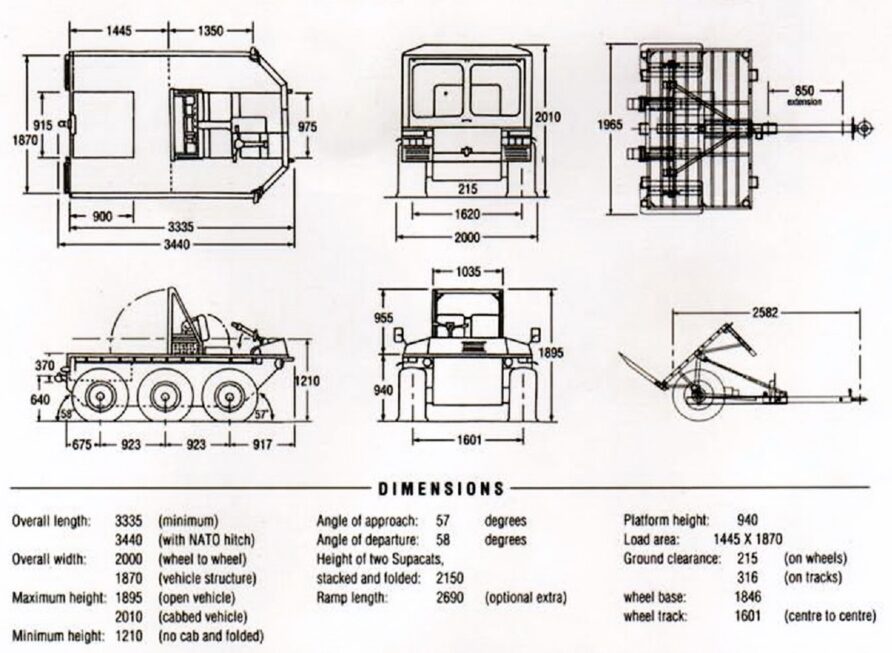

ATMP is a 6×6 vehicle that uses both skid steer and Ackerman-type steering (front two wheels steered)

It originally used low-pressure Terra-Wrangler tires, and with a ground pressure of 0.2 kg/cm, it was highly mobile, through several industrial consolidations, these are now Alliance 221 Tredlite tyres available under the Yokahama brand.

Originally powered by a 1.3L Citroën engine, the later versions had a 1.9L Volkswagen-Audi engine and automatic transmission.

Specifications include a 750-1,000 kg payload, increasable to 1,600 kg with reduced performance, gross vehicle weight of 3.45 tonnes, limited amphibious capability, and a top speed of 64kph.

The minimum ground clearance of the ATMP is 0.22m. The approach/departure angle of the vehicle is 45˚ while its fording depth is 0.6m.

The fuel tank has a 50L capacity, increased in later versions, providing a range of approximately 850 km.

ATMP is fully amphibious but only with a load of 400 kg payload.

Beyond that, and to provide additional stability, a floatation kit from All Terrain Vehicles can be fitted

ATMP has been fitted with Milan and Starburst/LML-guided weapons.

They have also been fitted with various roll cages, weapons mounts, and cabs.

H-ATMP features electric motors made by Dana TM4 and the vehicle can also export power to various off-board equipment. Further details here.

Click here for more information on KTPs at the University of Exeter.

Because the focus for ATMP was air manoeuvre and logistics, a great deal of thought was put into cargo handling ad weight/dimensional compatibility with in-service aircraft.

Towing and Load Handling

With a drawbar pull of 2.1 tonnes, ATMP has an impressive towing capacity.

In addition to clearing landing sites, the ATMP was also used for towing the L118 105 mm Light Gun complete with ammunition trailer, total carried and towed payload being exceeding 3,500 kg.

ATMP can tow a standard 3/4 Tonne Land Rover trailer

An ATMP-specific GS-type trailer fitted with the same tyres was also available.

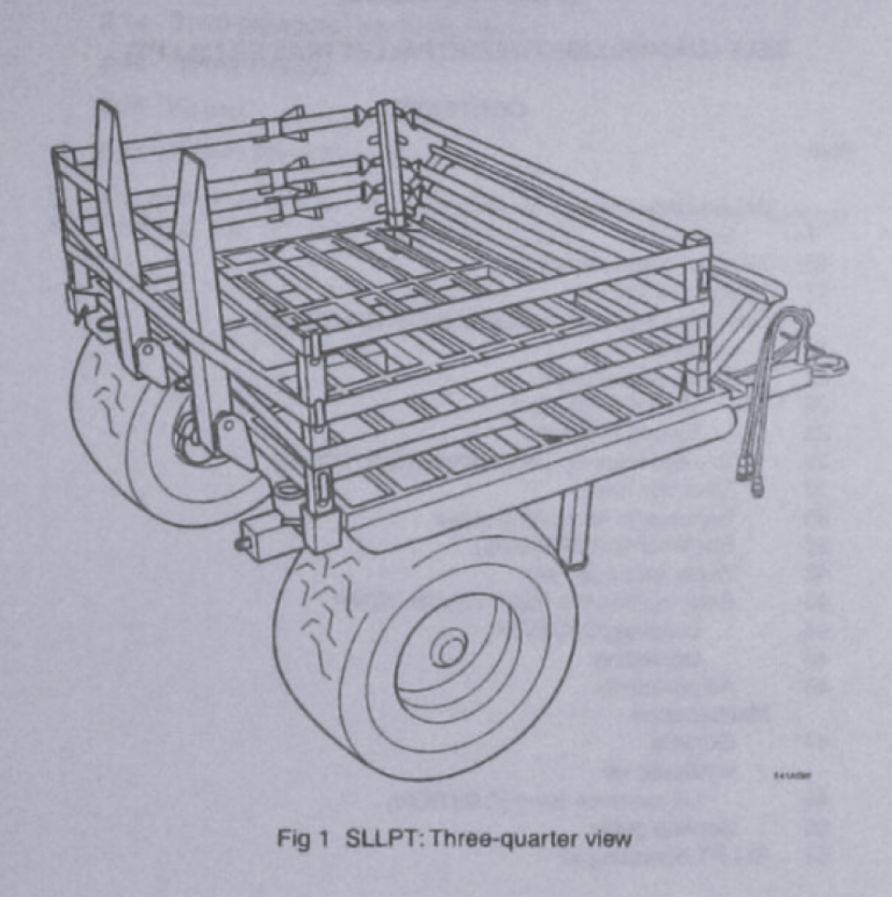

To increase carrying capacity and flexibility a pair of specially developed trailers were also introduced…

- FLPT (Fork Lift Pallet Trailer)

- SLLPT (Self-Loading Lightweight Pallet Trailer).

Although there are several variations, the basic trailer had a hydraulic tipping mechanism and pallet forks.

The driver would simply tilt the trailer into the down position, reverse onto the pallet, tilt the trailer back up, and drive away.

The maximum payload for the ‘flipit’ trailer was 1,400 kg, and it could also be converted to carry three stretchers.

Demountable corner posts could also be used to form sides for loose loads, with ratchet straps used to secure the load.

A 910 Litre Water Carriage Pack (WCP) was also available.

The conversion took only a few minutes and the posts were carried on the trailer.

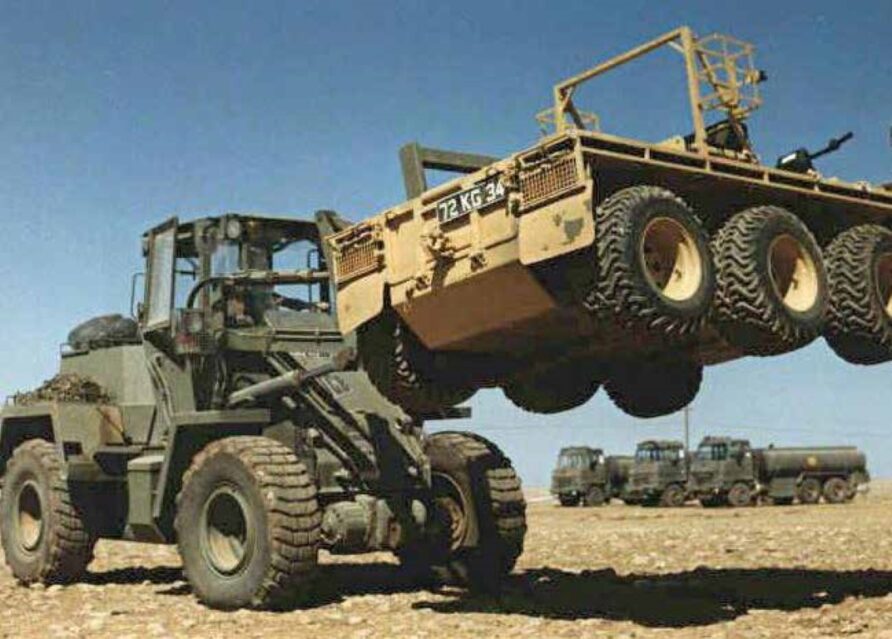

Both of these are unique, no other military all-terrain vehicle has this, loads have to be manually broken down or some form of external handling equipment or loaders used, as the image of Springer below shows well

It’s the little things.

The stowable ramps and winch could be used to haul loads onto the load deck.

Hydraulic lifting jibs were fitted to the Canadian export models for use by their Disaster Assistance Relief Team (DART)

Other users have also fitted similar equipment, able to lift a tonne at 2m outreach.

Although a civilian conversion, there is even a tipping load bed available.

Transportability and Deployability

The stowable ramps could also be used for short gap crossing, although Vickers Defence did create an MLC30 Short Gap Crossing systems that could be carried by ATMP.

The total weight was 710 kg but no single piece was heavier than 140 kg, the overall length was 5.2m, the maximum gap that could be spanned being 4m.

The bridge could be emplaced by a team of six in less than 15m.

Air portability was a key requirement

Between 1992 and 1993, ATMP was authorised for Medium Stressed Platform use, either two vehicles or one vehicle and a 105 mm Light Gun or trailer.

An Air Mobile Infantry Battalion would typically be scaled for 15 ATMP.

They could be carried by various helicopters as a sling or netted load.

Given the length of time that ATMP was in service, all necessary Joint Air Transport Establishment (JATE) clearances were obtained.

Chinook can carry four ATMP as an underslung load, two on the front hook and two on the rear hook, rigged as pairs. Sea King, Puma, Merlin, and even Blackhawk carriage schemes were approved.

Merlin and Chinook internal carriage were also certified.

Multiple stacking options also exist for carriage in larger aircraft such as the C130 and C17 on 463L pallets.

These stacking options also facilitated efficient vehicle transport.

It can even be moved by a forklift or telehandlers.

Specialist Versions

A fire tender version was produced.

The final ATMP version of relevance is the GKN FuelCat.

This was a system designed to support Forward Arming and Refuelling Point (FARP) operations for helicopters and fixed-wing aircraft.

One vehicle contains a generator, pumping equipment and fuel tank, and the other, a crane and trailer for another fuel container and pipelines.

GKN make the Air Portable Fuel Containers, currently in service in the Mk5 guise. The balloon-like, Kevlar-reinforced, containers, can hold up to two tonnes of fuel.

When full, the containers are 1.37m in diameter and can be towed, slung load under various helicopters and parachuted from tactical transport aircraft.

Between the two vehicles, they can carry 4,000 litres of fuel, pump it to multiple aircraft simultaneously, and provide aircraft towing and a gas turbine starting rig.

Summary

It is hard not to be impressed by the Supacat ATMP and yet, it is a good example of the British Army’s somewhat poor capability husbandry.

By not making timely investments in support and development, it had to resort to asking industry for an alternative when it was most needed because the OEM was busy with other things. Springer was a multi-million Pound mistake when a fraction of that money invested on a more timely basis would have prevented the waste.

The British Army has also invested considerable sums of time and money investigating alternative, mostly non-UK, vehicles. For exactly the role it invested in ATMP, the Robotic Platoon Vehicle (RPV) and more recently, the Low Technology Mobility Platform — Light and Low Technology Mobility Platform — Medium.

£4.5 million for the former and £2.5 million for the latter, perhaps these will include ATMP?

For the cost of one Ajax or CR3, we could probably revolutionise platoon and specialist load carriage.

Over the years, they have seen service with airborne forces, the Royal Artillery, Royal Air Force and Royal Marines, and with the MoD on range duties.

It is mature, flexible, adaptable, strategically and tactically deployable, and extremely capable, and now right up to date with electric and autonomy features.

Whilst 6×6 and 8×8 high mobility vehicles are common enough, none have the military heritage of the ATMP or have design features so well suited to practical load handling and transportation optimisation.

As I said above, it is the little things, that few notice, that make the difference, payload, load handling and transportability.

Nothing else comes close.

Change Status

| Change Date | Change Record |

| 08/03/2017 | initial issue |

| 04/05/2023 | Update |

Discover more from Think Defence

Subscribe to get the latest posts sent to your email.

With the Future All Terrain Vehicle (FATV) programme the Army may soon acquire another ATMP-type platform. This is a new requirement to support dismounted infantry by reducing the weight burden. It was recently described to me as 21st Century Bren Gun Carrier. Sounds interesting and if it can live-up to the Universal Carrier’s solid gold reputation, it should be great little asset. Not much is known at this stage, but we should learn more later this year assuming it doesn’t die.

A wheeled, AMTP style, amphibious capable, Universal Carrier concept, with a reinforced (pallet-sized) bed and optional jack legs for using as a solid platform would likely be incredibly useful.

i.e. An ATMP

Monty – I could be wrong but I think you have your wires crossed. The FATV is the replacement for the BV206, not a requirement for supporting dismounted infantry.

The experiments around supporting dismounted infantry has seen the DSTL buy Milrem THeMIS, Rheinmetall Mission Master and HORIBA MIRA Titan UGV’sfor testing. Also unfortunately I am not sure the unmanned ATMP Is included in that testing.

Just like to add a little further information on the FuelCat ATMP variant. The attached photos show the world’s first Supersonic Landspeed Record car, Thrust SSC: The FuelCat proved to be extremely versatile in not only refueling the Thrust Car at the end of each run but also towed the Car out onto the desert tracks, provided gas turbine engine start support, electrical power back-up and vehicle recovery

(additional photo)

In the picture of the loaded up Springer I think I am the guy cropped out on the right. I know the other 2 guys. If I remember right there was over 370kg of PE4 and barmines plus detcord, shock tube, sledgehammers and other ancillaries. Personal gear dumped on top. We used it all. That was a good day out!

Interesting to hear this “The FATV is the replacement for the BV206, not a requirement for supporting dismounted infantry” in the comments as I have been sure that some effort is ongoing, but totally unsure of the alternatives being looked at.

Marines are ‘dismounted’ a lot of the time… but of course they are not called ‘infantry’. And the logs support, often and in rough terrain specifically, is by BV206s.

It's such a good vehicle you have to wonder why the BA haven't gone all in and made the max use of it? What's not to like? Home grown too! Especially given the proponderence of light infantry…

Maybe it needs a make over? One thing I think it could maybe do with is a suspension system. It is very low to the ground and it must be hellish uncomfortable ride off road…

I seem to remember sending a Supacat out to the Falklands just after the war for trials. Memory not what it was but I think they may have crashed it!

blanket stacker. You are correct. I was in Falkland Islands from November 83 to April 84 serving in RAF. It was 'on trial' as far as we were told and only a Corporal, who had been trained for it, was allowed to use it. I cannot find any pictures of this Supacat 6 wheeler wearing it's rap-a-round rubber tracks, but I have them. We kept it and it's tracks in a 20 foot shipping container in the corner of the MT yard known as 'TRANDET' (Transport Detachment).