Nellie was the nickname used for a unique trenching machine that owed its existence to Winston Churchill, it was not, however, a great success.

Nellie — The Early Years

When Germany invaded Poland in 1939, Neville Chamberlain appointed Winston Churchill to the Cabinet as First Lord of the Admiralty. Wasting no time, he immediately revisited some of his older ideas about advancing to a trench line using mechanical means.

He foresaw an attack against the Siegfried Line as being an eventual necessity, and to do so, an armoured vehicle would be used to cut a trench through it. Other vehicles and dismounted personnel would follow behind and break out beyond the fortifications.

Although there are some different opinions of the origin of the concept. It was undoubtedly a widely held opinion that tanks would be as helpless against defensive works like the Maginot Line as infantry were against the trenches of Flanders, so it is easy to understand the general thinking.

His original requirement was for a machine that would burrow under the ground and emerge only at the required time.

The original nickname for the machine was ‘White Rabbit’.

After discussing the idea with the Director of Naval Construction (DNC), Sir Stanley Goodall, it was then passed to a former ship designer named JH Hopkins.

The concept developed slightly and estimates of a top speed close to 1mph (1.61 km/h) could be achieved, with the spoils forming a parapet to increase protection.

The project was moved to a new department in the Ministry of Supply called Naval Land Equipment, or NLE, or Nellie in short.

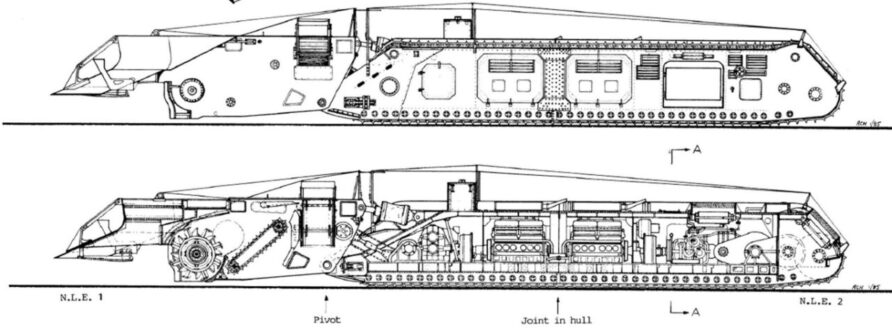

As the project progressed, the design evolved to include a combination of a plough that would remove the top half of soil on top of a drum cutter and a conveyor that would deal with the bottom half.

An examination of commercially available earthmoving equipment concluded that the Lincoln manufacturer Ruston-Bucyrus (who were in turn connected with the US manufacturer Bucyrus Erie) would be an invaluable source of expertise.

Together with Bassett-Lowke, a model was constructed for evaluation by the end of 1939.

Demonstration of the model was carried out in a sandpit in the basement of the Admiralty and in France, to a collection of British and French officers including General Gort.

It was reported that all were suitably impressed and, following a further demonstration for the Prime Minister and Chancellor of the Exchequer, authorisation to build 240 machines.

This initial batch was going to be split between forty large machines called ‘Generals’ or ‘Officers’ and two hundred smaller machines called ‘Privates’ or ‘Infantry’

The codename Cultivator Number 6 was adopted, and it was at this point that problems started to appear.

The original design used a Rolls-Royce Merlin engine but the Air Ministry had none of that, all Merlin engines would be for aircraft.

No other engine available had the power-to-size ratio that enabled the machine both to move and excavate within a reasonably sized body.

The team enlisted the help of Sir Harry Ricardo (yes, that Ricardo) who suggested the only practical alternative was a modified Paxman-Ricardo diesel engine.

This engine was called the Paxman 12TP, a twelve-cylinder high-speed diesel that developed 600 bhp.

It was developed from the 8-cylinder VR8, the TP standing for ‘Three Pieces’.

This was an important change that allowed the complex and difficult-to-machine VR8 engine components to be manufactured in quantity by a much wider range of manufacturers, with mass production considerations trumping all else.

Another opinion is that TP stood for Tank Propellant because the first TP prototype was actually for a heavy tank called TOG1, a design reminiscent of the WWI tanks.

Regardless of the origin of the term, the 12TP was no doubt an excellent engine, and diesel had many advantages over petrol for use in vehicles, but it was no Merlin.

This meant two engines, not one, a redesign resulted in both a larger and heavier vehicle which in practical terms meant it was unable to be transported by any in-service vehicle or trailer.

Work then started on 50-ton lifting jacks and tracked trailers to enable the prototype vehicle to be moved in three parts and assembled at its start point.

In May 1940, Blitzkrieg was unleashed on France and Low Countries, the tank was indeed still a key weapon, dispelling much of the conventional thinking at the time.

With trench mentality now firmly consigned to the history books, the concept that underpinned Cultivator Number 6, likewise.

In June 1940, Brigadier L Ling was appointed as a liaison officer between the NLE and War Office and after the fall of France, the codename Cultivator was dropped.

With this, so were quantities required, by the end of July 1940, the original two hundred and forty had been reduced to no more than thirty-three, twenty-five narrow and five wide, a training machine of each, and the prototype.

It was then thought it would be of immediate use in excavating tank traps or even destroying airfield runways in the face of a German invasion force, desperate times indeed.

Nellie Prototype and Testing

By June 1940, Ruston-Bucyrus had partially produced a prototype that could be tested but exposure to a broader range of ideas resulted in questions about what would happen if it broke down, and how would vehicles travelling behind get out of the trench.

Several others commented that in the era of dive bombers, the long trench would create a perfect aiming mark for the aircraft to align with.

A rear ramp was suggested, but this was soon dropped as the prototype progressed towards more comprehensive trials.

Side View

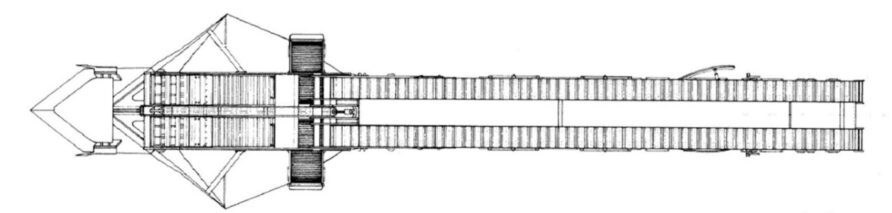

Overhead view

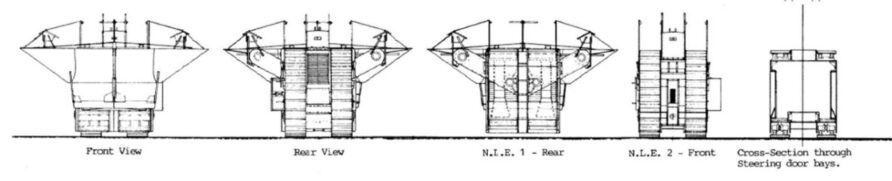

Rear and Front View

Even Churchill realised there were problems with the concept;

The change which has come over the war affects decisively the usefulness of “Cultivator No. 6”. It may play its part in various operations, defensive and offensive, but it can no longer be considered the only method of breaking a fortified line. I suggest that the Minister of Supply should to-day be instructed to reduce the scheme by one half. Probably in a few days it will be to one-quarter. The spare available capacity could be turned over to tanks.

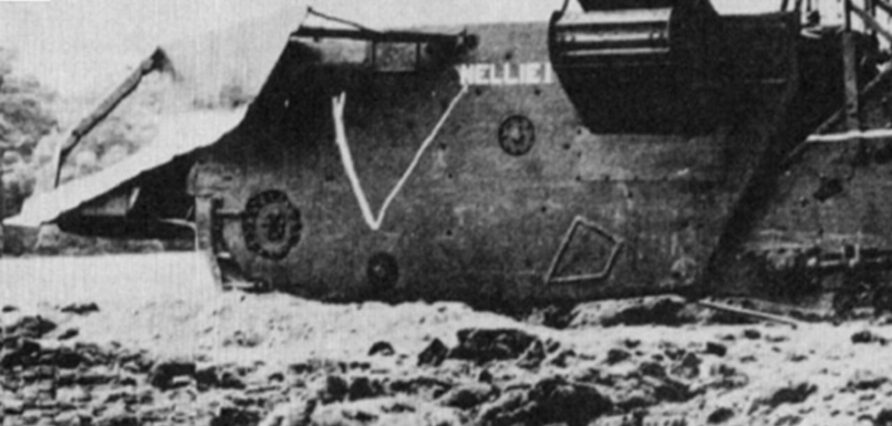

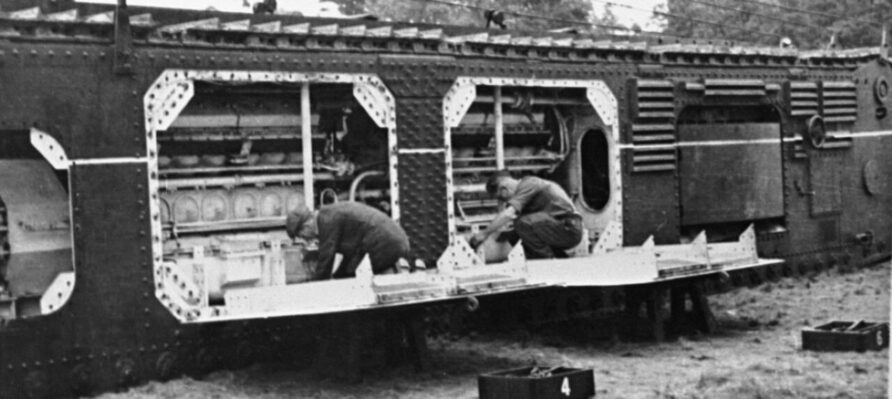

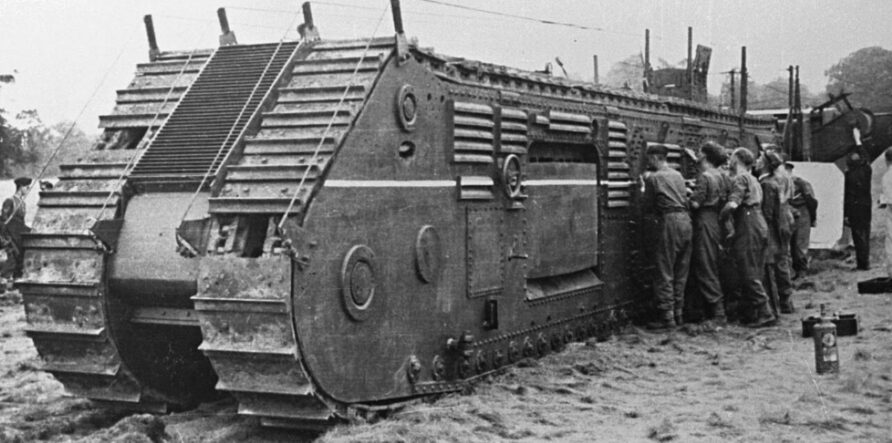

The ‘narrow’ prototype was completed in April 1941 and moved to Clumber Park Nottinghamshire in June for trials and testing.

Clumber Park was a former home of the Duke of Newcastle but at the time was abandoned, it was therefore away from prying eyes and the soil conditions were thought to be representative.

With a detachment of Royal Engineers (769 Company) the Ruston-Bucyrus team assembled the 90ft long machine but by the time the first demonstration was made in August, production requirements had reduced further to nine, with only one of the wide type.

The smaller ‘infantry’ variant was 77 feet (ca. 23 metres) long, 6 feet (ca. 183 centimetres) 6 inches (15.24 centimetres) wide and 8 feet (2.44 m) high.

It weighed 130 tons (117 tonnes) and had an articulating joint connecting the two sections.

The smaller front section contained the plough and trenching equipment with the rear section containing the two engines. A mile of trench produced approximately 7,000 tonnes of spoil that was arranged in 3-foot-high parapets on either side of the trench.

The operator was provided with an armoured ‘conning tower’ with two additional crew members squeezed into the cramped hull.

Conditions were said to be unbearable for even short periods of time.

Steering was also reportedly, ‘impossible’ although it must be observed, in the soil conditions it was intended for, it did the job it was designed for.

Winston Churchill visited Clumber Park on November 6th 1941 to see Nellie in action.

Further tests demonstrated that Nellie could be used as a mine plough, and it was moved from Clumber Park to Lilley Hoo near Hitchin in Hertfordshire for trials in heavier clay soils.

It was during this move that 769 Company RE discovered just how difficult moving a machine with a 1-mile turning radius would be.

The specially designed twin-tracked bogie 23-ton trailer required two Caterpillar D8 bulldozers to move (slowly).

The trailer was unbraked so going up or down inclines was especially challenging, requiring an extra pair of D8s.

The maximum speed was 4mph (6.44 km/h).

The War Office reduced the order again, clearly, without Winston’s enduring support, it would have been cancelled long before.

A requirement by General McReady to reduce its enormous turning circle and ensure it could produce a defilade every 100 yards (91.44 metres) was effectively the end of the project.

Despite that, it limped on until 1943 when the War Office formally cancelled the project, Winston Churchill declaring;

I am responsible but impenitent

Winston Churchill insisted five were retained, just in case, and they were moved to the 9 square miles of Royal Engineer stores at the Long Marston Engineer Stores Depot (1ESD) in Warwickshire. In 1946, four of them were recycled and the last one a few years later.

The site was sold to St. Modwen in 2004 and is now a housing development called Meon Vale.

All trace of Nellie, gone.

Legacy

Although it could be considered a failure, both in concept and delivery and a significant waste of resources, there were two things that came from the project that had value.

The first was the trailer, after additional development, it was eventually used as a recovery trailer for the Churchill Armoured Recovery Vehicle (ARV), called the 45-Ton Tracked Recovery Trailer, designed by Cranes (Dereham) Ltd and manufactured by Boulton and Paul.

It was used on the Normandy beaches by the 79th Armoured Division and to move locomotives from LCT’s.

Perhaps more significantly, the Paxman Ricardo 12TP engine was adapted to meet a Ministry of Supply requirement for landing craft engines. It was modified to make it suitable for marine use with a deeper sump and other marinisation features. The 12TPM went on to power more or less all British Landing Craft (Tank), with over 2,500 being delivered.

Read more about Paxman engines at the superb Paxman History Pages

Footnote

In 2019, The National Trust commissioned a replica of Nellie to commemorate the role of Clumber Park in WWII

Change Record

| Change Date | Change Record |

| 07/03/2018 | initial issue |

| 11/09/2020 | Update to National Trust replica section |

| 22/07/2021 | Format refresh |

| 30/08/2023 | Update and new images |

Read more (Affiliate Link)

Discover more from Think Defence

Subscribe to get the latest posts sent to your email.

Thx TD, I knew about Nellie, but locomotives delivered to the Normandy beaches… and beyond (thanks to the project)! Learn something new every day…

My dad was the pilot of Nellie in Clumber Park, he was driving it when Churchill was there to see it. He used to tell me about when it got stuck and they had to dig him out!! My dad was originally from Preston it’s how he met my mum in Worksop and married.

Thanks Kev, great story

In addition to the immediate spin-offs, I wonder if this project ultimately "broke ground" in the development of technologies that would lead to things like the tunnel boring machines we have, today. It's interesting to look at so-called "failed" projects and speculate that, but for that experience of failure, and all the research and development of components and designs that went into them, would there have been the legacy of technical expertise that was needed to develop other technologies, decades later?