Work has commenced on a new port facility at Port Stanley that will replace the post-conflict FIPASS.

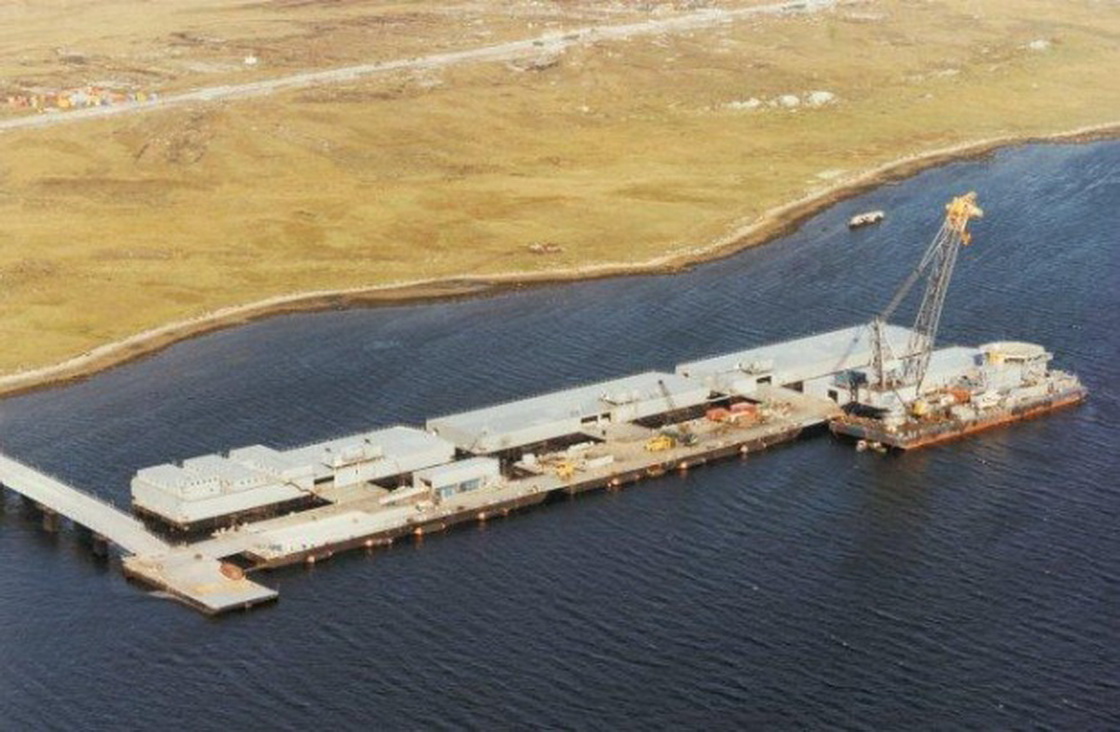

Probably the most ingenious and revolutionary bit of ship-to-shore logistics capability that no one has ever heard of, FIPASS was deceptively simple.

It was not used until a few years after the conflict, but is worth describing here as it sets the scene for recent developments. Soon after the liberation of the Falkland Islands, the construction phase for the airbase at Mount Pleasant and Mare Harbour commenced.

This meant a considerable influx of construction personnel, equipment, and materials.

The existing techniques of offloading using Mexeflote’s and RCL, whilst ideal for amphibious operations, simply could not cope with the increasing volumes. The offload facilities at Port Stanley were woefully inadequate, despite some improvement works completed by the Royal Engineers.

This resulted in excess demurrage costs and a large bottleneck as ships were unable to unload in good time.

The Government advertised for innovative solutions to the problem and the tender was won by the Middlesbrough company, ITM Offshore, which had considerable experience in offshore construction. Unlike the other proposals, their solution was planned to be operational in 5 months.

Based on technology and systems developed for the North Sea oil industry, the Falkland Islands Intermediate Port and Storage System (FIPASS) was designed to resolve several issues; port access, refrigerated warehouse space and personnel accommodation.

Six North Sea oil rig support barges (about 10,000 DWT each) were connected and linked to the shore via a 600-foot causeway, with a final and smaller barge acting as a floating link span. This was also used as a RORO interface. The facility also made provision for stern-on mooring and 300m of conventional berthing.

Four of the barges carried warehouses, with provision for refrigerated storage. In addition, there were accommodation offices, which included a galley and messing facility for 200 persons.

A key point is that it was not only a berthing facility but also had significant storage.

The linkspan and causeway were designed and installed by MacGregor Navire (now Cargotec), Harland and Wolff the accommodation facilities and Nuttall installed the mooring dolphins.

After construction was complete, it was transported south on two heavy-lift FLOFLO vessels, the Dyvi Teal and the Dyvi Swan in a phased lift that matched the construction schedule

The heavy-lift ships were faster and safer than towing.

The large ships also carried a crane barge that was used in the construction process.

Once in the Falkland Islands they were floated off the heavy lift vessels and installed by ITM staff and Royal Engineers who had previously built all the necessary connecting roads, including one to the Mount Pleasant construction site.

The first cargo ship to use Flexiport (MV Leicesterbrook) unloaded 500 tonnes of general cargo and 60 ISO containers in 30 hours.

By way of comparison, the same load/offload using Mexeflote took 21 days. Larger vessels would take up to a month to unload using Mexeflote’s, it was a massive improvement.

Writing about the harbour after FIPASS was up and running, a writer for the Falkland Islands newsletter wrote;

Latest reports from the Falkland Islands are that Port Stanley now looks rather empty

All this cost £23 million, or about £50 million in today’s money, but it saved a small fortune in keeping refrigerated vessels offshore and floating cold stores. It also speeded unloading up immeasurably. In fact, it paid for itself in less than 2 years due largely to the excess shipping costs being eliminated.

A couple of years after its initial deployment, FIPASS was gifted to the government of the Falkland Islands.

Since then, it has operated continuously and is now managed by ATLink

As part of continued economic development plans, it is now about to be replaced. The existing facility is old, and a recent incident where a Spanish fishing vessel collided with it whilst berthing caused a temporary closure.

Nutall (now BAM Nutall), the company responsible for the FIPASS pile installation, will complete the construction of the new facility. It will have a solid structure, not piled and floating.

Read more (Amazon Affiliate Link)

At the end of the project in 2024, FIPASS will be removed after 40 years of service to the islands.

Discover more from Think Defence

Subscribe to get the latest posts sent to your email.