A proposal from Anglo Engineering Concepts to meet British Army vehicle capability gaps and drive down support costs by adopting system engineering thinking and a design language that places the designer closer to the user.

Anglo Engineering Concepts is run by an experienced design engineer that formerly worked as one of the three design engineers in the Drawing Office of Alvis. The design engineers’ remit was to bring forward realistic innovation – this approach of creating designs stretching beyond current capability that could be manufactured in the near future from available technology has since remained a core design principle.

In more recent times, this same design engineer was part of the team that created Lockheed Martin’s AVA wheeled vehicles that were exhibited at the DE&S DVD events.

The designs described below have been reviewed by serving Army personnel, by MOD and DSTL personnel, and by various experts in the industry, including the former Manager of the Alvis Drawing Office. Generally (and it is to be hoped not just out of politeness) the designs have been well received.

Some design choices caused concerns, but wherever possible these concerns have been addressed in subsequent revisions. This highlights another core principle behind the design work – that solid direct communication between designer and user is essential to effective vehicle development.

A Short History

When the MOD embarked upon a replacement programme for CVR(T) it at first seemed, under FFLAV, that modern, more capable and better-protected versions of the Scorpion family were sought. This seemed rational; there are tasks ideally suited to small-light-fast armour which MBT-sized vehicles or up-armoured Land Rovers cannot perform as efficiently, if at all.

FFLAV though did not progress to a procurement programme.

The TRACER study that succeeded FFLAV was far more ambitious. As the TRACER programme progressed, the vehicles grew larger and heavier, although still nowhere near MBT size. There seemed to be a capability gap opening up between Land Rover-sized CVR(T) and this new breed of digitised high-tech reconnaissance vehicles.

Many in the industry saw a need for light armour and moved to offer solutions – Stormer 30 being an obvious example.

When FRES described a need for C-130 transportability, simple, light and upgradable armoured vehicles like Stormer 30 were brushed aside as the new programme would deliver exactly that class of vehicle, only better.

Skip forward many years; as we all know, FRES eventually delivered something that is the width and height of an MBT, at half an MBT’s weight and with half an MBT’s engine power.

When FRES turned heavyweight, BAE toyed with what seemed to be a relaunch of Stormer 30, the hull updated and apparently carrying a version of their FRES CV90 prototype turret possibly armed with the Mk44 Bushmaster cannon, but it appeared only as a low fidelity graphic:

This vehicle, it seemed, never reached the prototype stage, but CVR(T) derived designs continue to emerge – there are rumours another Stormer 30 rebirth is imminent but yet to break cover – which only shows how good the CVR(T) concept was way back in the 1970s.

Anglo Engineering Concepts sprang from a conviction that Ajax could not perform the same tasks that CVR(T) suited, and where size and weight were defining requirements. Several vehicle concepts were created, assessed, and either set aside or carried forward for further development.

This coherent design and development process has been ongoing for over seven years. Seven years of design effort aimed at a single family of armour — this is a duration of design effort not seen since the days of the Establishments.

The effect the closures of the Establishment had on UK defence equipment design was fundamental. The MOD assumed the industry would perform all the work previously done by the Establishments, but cheaper!

Of course, it didn’t.

The industry is not a charity; unless there’s a high probability of a good return on its investment, it does nothing. Without a cast-iron contract, or a winnable competition for one, or at least a clear indication from MOD that they have a clearly defined requirement for a specific capability, there will be no design effort in the industry.

And as soon as the opportunity expires, all design effort stops. Dead. There should be no surprise that since the 1990s, nearly every armour bid has been based upon previously fielded products minimally modified to tick the latest requirement boxes, or on products imported from afar, developed on their nation’s taxpayers’ money.

This is perfectly summarised in one simple quote from William Suttie’s book ‘The Tank Factory’, where he is looking back at the 1920s.

“The decision to focus tank design in industry and run down the experienced and innovative Department of Tank Design (DTD) was a significant factor that resulted in Britain becoming a backwater in tank design until the Chertsey Establishment was established.”

Clearly, that was a lesson not learned.

In this modern environment, the sustained focus of design effort is a rarity and has delivered not so much a set of vehicles, as a design system comprising a set of subsystems and components that by use in different configurations permit rapid development of role-specific vehicle types.

The designs resulting from this methodology have been created and developed despite there being no MOD procurement project, formal requirement or funded study.

These are simple honest vehicles designed from the inside out to be effective, maintainable, and achievable, but just as important is the design process that produced them.

Anglo Engineering Concepts — Family of Light Armour

While it has been the norm for the Armed Forces to do the best with the kit which is available, this has at times made tasks more difficult, less effective or in some cases much more dangerous. Gaps in capability place additional strain on the serving soldiers as they wrestle with equipment that is not really the right tool for the job.

What is needed is a wider range of useful tools in the Army’s toolbox, so that the difficult task of the soldier can be made as easy as possible.

The most obvious gap in UK equipment is precisely the space that has been occupied by CVR(T), and FV600 before that, and the likes of the Daimler, Coventry, and Staghound armoured cars before that. Considering the age of FV432 Bulldog and M270 MLRS, ongoing concerns over Panther protection, and the mobility of the Mastiff family, there is a broad spectrum of light to medium armour that might be considered also in need of replacement.

It appears the US Army has determined it too has a similar need for such armour (as reported here:

https://www.army.mil/article/184597/

The vehicles broadly align within the earliest FRES framework; C-130 transportable combat armour fulfilling many of the defined FRES roles. But before embarking on a design, their purpose had to be adequately defined. As one of the VERDI-2 trials operators (LCoH Bright) stated at the end of its trial:

“The main question to be answered before TRACER comes off the drawing board is what is the main role of recce? What does it need to do, collect information or destroy enemy light armour or both?”

The first task faced by any armoured vehicle designer and the user is to understand the role; to scope out something like a Cardinal Points Specification of perhaps half a dozen defining characteristics the design needs to have. Without such a CPS the created armoured vehicle may not fit comfortably into any role – a square peg looking for any vaguely square-shaped round hole into which it can be forced.

Once each role had its defined purpose, a brief study was carried out to investigate the problem space, including reviews of the strengths and weaknesses of earlier vehicles to pick out valuable features to carry forward to new designs. Ever since the invention of the tank, armoured vehicle designers have come up with very clever solutions to problems that are as relevant now as they ever were.

Incorporating these, together with modern systems and approaches is in no way outdated thinking; the external shape of the new designs merely reflects the packaging of the necessary subsystems and human factors, taking those earlier smart solutions which have been brought up to date into account.

There may be raised eyebrows at the imposed C-130 transportability constraint given that the UK now has A400M, but there are sound reasons to work with this constraint. Firstly, the 9ft (2.74 m) by 9ft (2.74 m) gauge and 18t weight limit are entirely appropriate for a family of vehicles to replace CVR(T) and other similar light armoured vehicles.

Secondly, while the UK has A400M many of our allies do not, and the flexibility of deploying as part of an ally’s force seemed worth retaining. Thirdly, complying with the C-130 gauge also makes rail and road transport much easier, ensures slick RO-RO operations, and keeps the vehicles down to road vehicle bulk such that few routes would be impassable using the extant infrastructure.

Finally, holding to C-130 constraints maximises export potential which would be of value to UK PLC.

The counter-argument most often pitched at this is that in the contemporary operating environment, the light armour of such compact form cannot meet the protection levels necessary to survive the most likely threats. This would be a valid argument if the entire fleet of armour was to be changed to sub-20t vehicles. but the Army will still have its 70t MBTs, 38t Ajax, 30t+ upgraded Warrior and MIV, which is likely to be a 35t vehicle.

If threats are so severe, then field the kit appropriately but accept the limitations they bring; the restrictions on routes, the greater logistic tail, and the reduction in stealth (visual and IR but particularly noise). On the other hand, where rapid reaction and get-to-anywhere mobility are key, using a light small mobility-focused armour capability has its advantages.

Different tools for different jobs.

Low weight does not necessarily mean paper-thin protection. These smaller vehicles have been designed with a thick and heavy hide but due to smaller surface areas, the weight of equivalent protection armour is less than would be seen on larger armoured vehicles. There are also some very intriguing new developments in passive and reactive forms of protection, and many active forms of protection are now being marketed.

Clearly, the cost is key as in all projects, but this points towards better-than-expected protection in smaller and lighter platforms.

Those who follow TD’s daily feed of defence-related snippets will recall this comment: “Start with a common engine, wheels, tyres, transmission & other bits, then, AND ONLY THEN, build vehicles around them.

Systems thinking.” Those who cut their teeth in the UK defence industry of the last century have always sought to use common components and subsystems, a discipline that the Government Defence Establishments promoted, encouraged and sometimes enforced. No surprise then that exactly this approach has been followed with the vehicle concepts described here.

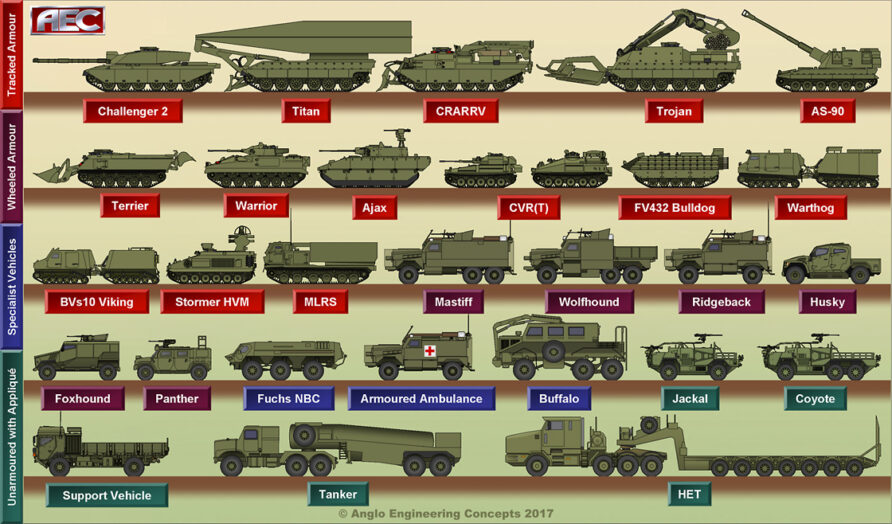

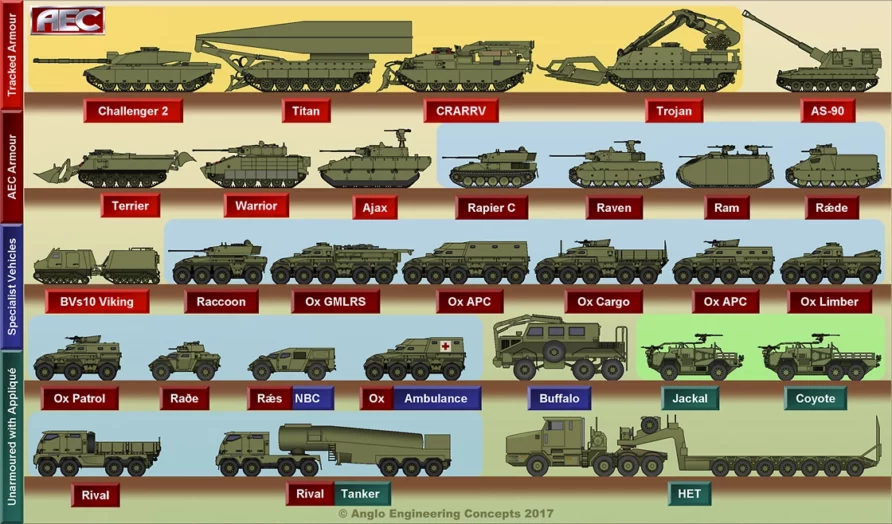

This graphic shows each current vehicle type drawn to the same scale; it is not exhaustive or definitive, for example, no armoured JCBs nor Command or Engineer or Repair/Recovery Variants of all the types depicted, but it does indicate the broad and varied nature of UK armoured vehicles.

Some armour is very new, some are ages old, some have aged well and others badly. Many have been purchased as Urgent Operational Requirements when existing fleet shortfalls were identified, and some of these may not be retained in service in the medium term.

What is quite plain to see is that there are many types, each filling a niche role, all needing their unique equipment care and REME support to keep working. That is a lot of different vehicles with different spare requirements and different maintenance procedures.

Anglo Engineering Concepts — Vehicles

Shown below is a brief outline of the vehicles, their purpose, and some development rationale as the process evolved. They are each valid Light Armour solutions as they stand, but it should be understood that they also serve as examples of the wide variety of armour that the design approach can deliver.

They may be viewed as vehicle proposals or equally a basis for further development. They did not come about all at once but progressed over the development period in response to user feedback and other inputs.

The 3D images are taken from CAD where the vehicles have been modelled. The CAD models are not complete production-ready designs but do serve as packaging exercises and allow some degree of human factor and maintenance assessment.

Anglo Engineering Raven

Role: Fast Light Armoured Fire Support; Reconnaissance Vehicle

Design: The initial concept was nothing more ambitious than a low-profile hull on which either Ajax or Warrior CSP turrets could be mounted to provide obvious commonality and support advantages whilst also providing a lighter lower-profile fighting vehicle than an IFV.

Not as easy a task as imagined, modern turrets are huge compared to those of years ago; a function of larger guns, elaborate feed systems, a lot of electronics to house, the requirement to accommodate physically larger soldiers and the space demands of body armour and wearable personal technology.

There has apparently been a loss of focus on designing armour to the minimal possible dimensions over the years. This may be a simple consequence of moving to CAD – if the design only exists in the virtual world, it’s difficult to grasp the reality of internal space. There is also a significant reduction in the rate of new projects compared to previous decades, meaning engineers are just not using their skills often enough to gain the all-important knowledge that translates to experience and technical intuition.

There is a school of thought that the use of automated design tools in place of experienced designers will make better products, but this is far from proven.

For a combination of some or all of the above, Ajax and Warrior CSP turrets are large. During the evolution of the design process, it became clear they could not form the basis for a CVR(T) sized vehicle and in addition, their asymmetric width creates issues on small vehicles.

After a good deal of concentrated options assessment, a configuration was found that created a balanced vehicle that worked using either of these British Army turrets or either of the two BAE Systems proposed Warrior CSP and CV90 FRES turrets.

This vehicle was named Raven, and for the purposes of illustration, the third-party turret with which it has been fitted is the BAE Warrior CSP turret, selected before the MOD decision was made to buy Lockheed Martin turrets for Ajax and Warrior CSP.

There are some unusual design decisions embedded in the hull design which significantly improve personnel protection without adding weight. This vehicle tips the scales at approximately 14t. As might be expected, it has a crew of three, but perhaps not as expected it also has a high power-to-weight ratio giving a very lively performance.

In subsequent reviews, serving British Army representatives voiced concerns and reservations over some of the more radical technical choices involved in the hull design.

Anglo Engineering Rǽde

Role: Armoured Personnel Carrier

Design: The low-profile Raven hull had its roof plate raised to create a personnel carrier. The resulting vehicle, called Rǽde, has a similar internal volume to the Alvis Stormer APC. But where that vehicle was defined as 2 crew plus 10 dismounts, using the 97th percentile male soldier anthropometric model that is now demanded, reduces the capacity to 5 dismounts.

The current Def Stan requirement is that vehicle seating must be separate and well-defined with restraints and supports, and where possible arranged facing fore/aft. If all the non-mandatory guidance is followed, when there is a seating capacity of five, five is all that can be carried. Older military personnel carriers would be fitted with benches or close-coupled flat-squabbled seating facing side-on.

While there would be a nominal seating capacity, the seating arrangement could take more at a crush in emergencies. Following all Human Factors guidance has implications that must be understood.

In the AEC designs for Armoured Personnel Carriers, the seating for dismounts is blast-attenuating but side-facing, and while the seats are individual and shaped, they are close enough to their neighbours to act as a bench when necessary.

With the cancelling of Warrior CSP, a trial fit of the Rapier remote turret on the Rǽde hull has been given an initial assessment. The turret requires a well in the outer armour of the hull for the ring and RBJ (the slip-ring unit for electrical connection) which constrains dismount compartment headroom, added to which the significant weight of such a turret on a light armoured vehicle would lead to lateral instability.

This IFV version would also exceed the C-130 transport gauge due to excess height. While it might seem an attractive fightable concept, the penalties are not insignificant, and operating APCs in concert with fire support such as Rapier or Raven would probably deliver a more robust combat effect.

Anglo Engineering Ram

Role: Close Combat Support; Assault Gun

Design: With a fixed forward-firing 25 mm Oerlikon KBA or CTA40 and two Selex Enforcer RWS, the Ram is designed for close assault in urban and semi-urban terrain. With one RWS, the opposition may approach if it is focused elsewhere, with two RWS the probability that neither is about to sweep for threats is small.

To aim the hull gun, the vehicle must be aimed much like the S-tank, and like the S-tank the hull attitude can be adjusted in this case by air-suspension units. The flanks are designed to support heavy anti-IED/RPG slab armour, making this vehicle both heavy and wide.

Ram has not yet been transferred into CAD.

Anglo Engineering Rival

Role: Protected Cargo Vehicle

Design: In a complete change of direction, there was a request to investigate if the technology of the tracked vehicles above could be re-engineered into a wheeled chassis, specifically, in this case, a chassis for an existing armoured cab, to be configured as a drop-side cargo truck.

The exercise proved successful and resulted in a cargo carrier of modest size and payload capacities between 8t and 11t and room for six NATO standard pallets on its conventional drop-side load deck.

At a late stage, the Design Authority for the cab decided it was not to be used. An alternative AEC cab was created on the same footprint and with the same mounting interface to suit the chassis. The cargo deck and dropsides were modelled on the excellent Marshall’s products used on current British Army MAN/Rheinmetall cargo vehicles.

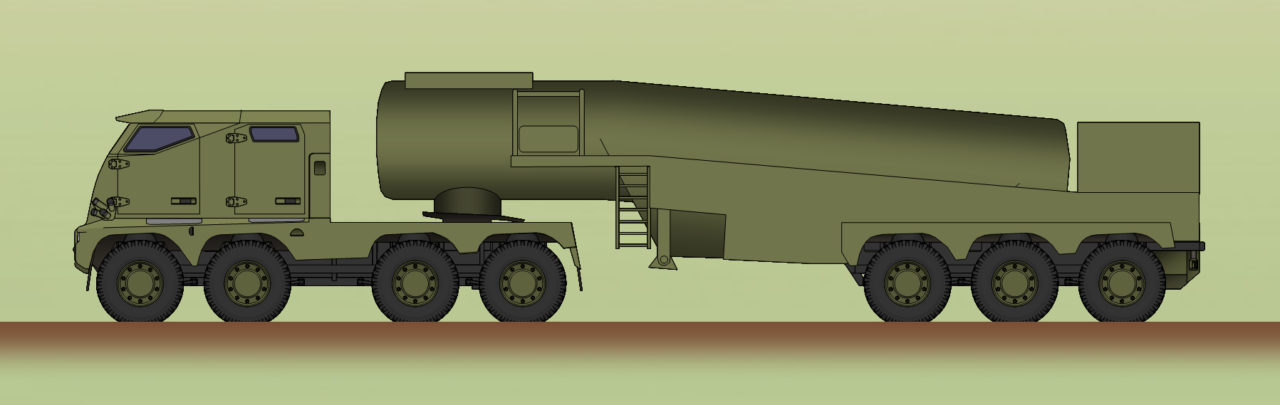

This could also be adapted to the protected tanker role.

Whilst the suspension and general layout meet the requirement, at between 6.5t and 8t per axle it was too demanding on available technology. The axle rating was reduced to 3.5t per axle for all other wheeled vehicles, making these lighter vehicles feasible within current technology, but the geometry and configuration of the suspension remain the same.

A note about this geometry; a request was made to the designer of Jackal, and he kindly defined the trigonometry of the suspension. The suppleness of wheel movement will be equal of Jackal but at 3.5t the axle loading is less and the tyre width greater, which allied to the high power-weight ratio makes the fully armoured vehicles’ theoretical mobility considerably better than the impressive Jackal

Anglo Engineering Ræcc

Role: Autonomous Engagement Capability; Armoured Car

Design: The first of the wheeled vehicles using this 3.5t axle loading was perhaps an odd choice. The lack in the UK Order of Battle of high-speed high mobility firepower capable of long-distance transits and being able to counter a broad spectrum of threats seemed to be a capability gap worth filling.

The four possible UK turrets (one each for FRES and Warrior CSP from BAE Systems and Lockheed Martin UK) did not fit well on a vehicle designed to be small and mobile, not only because of their size and weight but also because the turret basket size did not suit this vehicle’s narrow V-hull. A more comprehensive selection of firepower was also required.

A new remote turret was designed, armed with the CTA40 and with Anti-Aircraft and Anti-Tank Guided Weapons installed conformally. The turret also has an elevating sight – it only rises a few feet, but as one RAC Major commented, he had found standing on the turret top with a pair of binos a very effective way of seeing without being seen; he didn’t see the limited elevation as a handicap.

The hull has room for just two crew, but then the gun has its autoloader and the missiles are in essence ready-rounds, and the 7.62 mm coax was given large ammo can use, so much of the gunnery effort was taken care of by machinery and advance vehicle preparation.

The turret was set on an 8×8 hull of low profile and of a deep V profile in which the crew operated, and sat in a well-protected citadel using the array of electronic vision options for driving targeting and situational awareness.

A point to consider here is that LCoH Bright after the VERDI-2 trial stated the following:

“The trial on Salisbury Plain was a success in as much as it proved a two-man crew can operate effectively for 48 hours in a closed-down environment, and it opened our eyes to what is available to the recce soldier of tomorrow […but…] it must be smaller and faster.”

The Ræcc vehicle concept, like VERDI, is a two-man vehicle, with electronic vision and a remote turret, but packaged small enough to fit C-130 and just possibly light enough for CH-47 lift and has mobility and speed in Jackal’s class. That’s all LCoH Bright’s wishes fulfilled.

It was presented to a group of the Army that has the remit to embrace and assess new developments. But where Raven raised some concerns under review by the User group, Ræcc raised considerable objections. The reliance upon electronic vision, no ability to get the commander’s head out with a clear sight of all sides of the vehicle, difficulties with misfires and ammunition feed stoppages and on and on.

So despite the outcome of the VERDI-2 trial, when offered just what that trial’s team recommended, it was the User who rejected unmanned turrets and solely electronic vision.

Quite disappointing, but the point of the AEC design approach is that the same building blocks may be moved and recombined with a high degree of configuration flexibility, so the rejection of one particular vehicle configuration does not mean a start from scratch.

A redesign then…

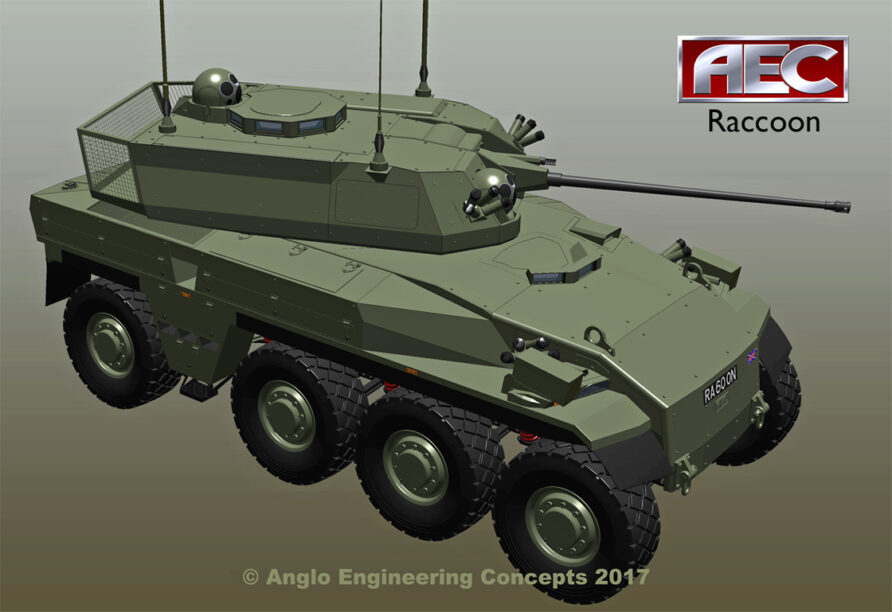

Anglo Engineering Raccoon

Role: Autonomous Engagement Capability; Armoured Car

Design: Raccoon is still an 8×8, but now with a one-man turret.

To accommodate one man, the turret is physically larger and has a reduced number of missiles. And of course, it now has a basket that occupies much of the hull. The hull too needed redesign, with effort upon retaining some crew protection mechanisms employed in the earlier Ræcc hull. It grew a little taller, the turret moved further back.

It is not as compact as Ræcc, but one of the opportunities the redesign brought was the provision of protected missile stowage for two of each GW type, armoured both from the outside world and from the crew citadel within.

Anglo Engineering Rapier-C

Role: Reconnaissance Vehicle

Design: The turret of Raccoon, complete with both natures of guided weapons, is still more compact than the Ajax and Warrior CSP turrets. The next task was to see how much smaller the tracked hull could get if this one-man turret was to be used.

The hull width was reduced as the basket is a smaller diameter; the L/C ratio that defines tracked vehicle steering behaviour allowed a shorter run of track on the ground as the vehicle was narrower, there was (just) enough room to get two crew, driver and gunner, side by side in the hull and room for the engine bay behind the turret basket.

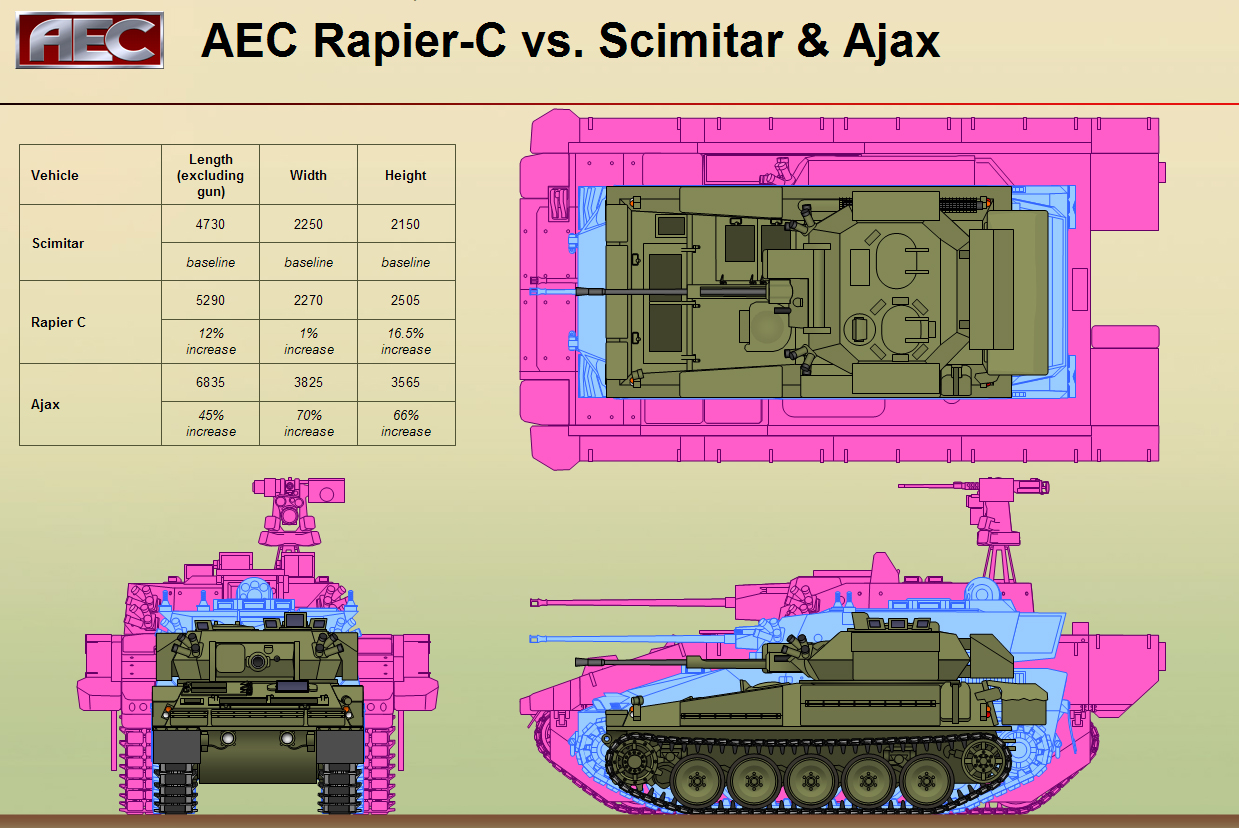

This compact vehicle called Rapier-C ended up very nearly CVR(T) scale.

Rapier-C is a tracked vehicle as narrow as a Scimitar (if track guards are omitted) and a few per cent longer and taller, with a crew of three, and with CTA40, 7.62 coax, ATGW, Anti-Aircraft GW and an elevating sensor.

It has low ground pressure within 10% of that of a Scimitar and a very high power-to-weight ratio that provides astonishing performance. With the removal of track guards, antennas and the upper EO/IR sensor, it fits into an ISO container.

It is perhaps worth pausing here to compare and contrast with Ajax. Many will not have seen Ajax in the metal and will base an idea of scale upon photographs. Face to face, it really is imposingly large as are most new armoured vehicles, but for those who remember the compact dimensions of Scorpion/Scimitar/Sabre, this is a real step-change.

To help appreciate the size difference in absolute terms, the image below provides a comparison, Scimitar the blue-coloured vehicle is Rapier-C, and the pink outline is Ajax. Each to scale

There is no doubt that once in service, Ajax will be a competent vehicle and there will be situations in which it will be the ideal fighting vehicle to use. Would these be situations where similarly armed, similar weight Warrior CSP couldn’t be used with similar success?

Or similarly, armed similar size and weight MIV? Or even Challenger 2 which is similar in width and height and has only 25% greater ground pressure under its tracks?

Possibly, possibly not, but it is a fair bet these other vehicles could be more readily substituted for a missing Ajax far better than an Ajax could be substituted for a missing Scimitar in situations ideally suited to the CVR(T) capability

Anglo Engineering Rapier-A

Role: Reconnaissance Vehicle

Design: A predecessor to Rapier-C, Rapier-A was a concept using the remote turret of Ræcc complete with CTA40, coax, SHORAD and ATGW and its elevating surveillance sensor, offering better personnel protection than Rapier-C in a smaller package yet, but at the expense of Mk1 eyeball direct vision – a proper VERDI-2 capability in a Scorpion sized vehicle – but currently shelved due to the User rejection of reliance upon remote electronic interaction with the outside world.

Anglo Engineering Raðe

Role: Fast Scout and Liaison

Design: Following the FCLV debacle and the continuing run of rumour and disquiet that Panther may not suit the role for which it was procured, and to see how compact a vehicle the standard wheeled driveline and suspension set-up would support, a vehicle similar to Ferret was constructed.

This was Raðe – a two or three-man vehicle, rear-engined. Originally penned to take the Thales (ex-Helio) FVT800 turret, it seems Thales has withdrawn this. So a similar turret fitted with .50 cal and a 7.62 mm chain gun was created. With the one-man turret, there is only room for the driver to sit ahead of the basket front & centre; with a remote weapon station, two personnel would easily be accommodated behind the driver.

Two axles hence 7t all-up mass, overall dimensions not dissimilar to CVR(T) but obviously with greater ground clearance.

For comparison, this is not of the Ferret scale. The reason is simple – there is no way a vehicle of Ferret size could accommodate two 97th percentile soldiers, let alone the three that this vehicle could accommodate. Raðe is similar in dimensions to the Coventry Armoured Car, and both wider and taller than CVR(W) Fox

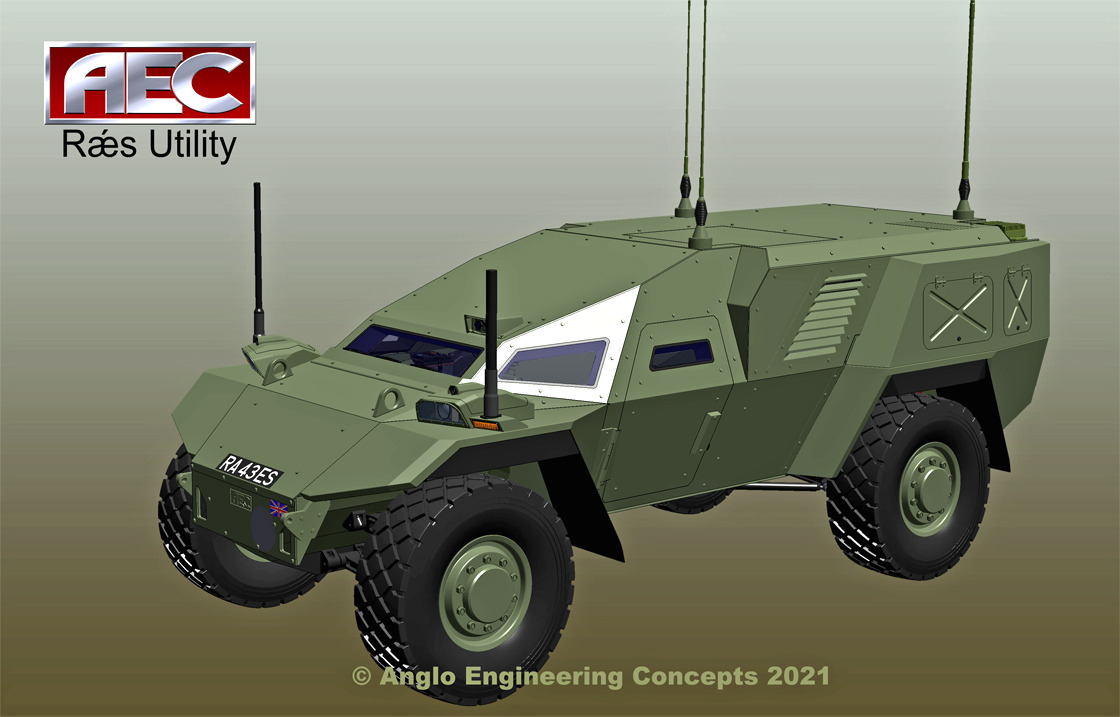

Anglo Engineering Rǽs

Role: Civil Order Policing; Military Utility

Design: Using Raðe as a starting point, a Utility Variant was drawn up called Rǽs. To create a usable rear access cargo compartment, the engine bay was moved to the side just in front of the rear wheel. The wheelbase had to extend to make the space, meaning this is the only wheeled vehicle that fails to meet defined HMLC criteria, due to break-over angle.

While the cargo space is limited, the vehicle retains the same armour protection as all other vehicles. The siting of the engine bay means there is no room for a turret basket, so RWS or a simple head-out machine gun would be the self-protection measures.

The vehicle was designed to adopt roles that FV1611 (Humber Pig) would have undertaken; riot control and civil order policing.

Anglo Engineering Ræcc-R

Role: Autonomous Engagement Capability; Armoured Car

Design: At a briefing to British Army personnel new to the AEC concepts, it was suggested the mix of ATGW and anti-aircraft guided missiles on Raccoon was flawed, not because they were technically incompatible but because the level of training to get one crew competent on both missile types was unlikely to be provided.

Better to fit just ATGW and a gun, they said. Another redesign then.

Removing one of the missile systems allowed the turret profile to reduce back to that of the unmanned turret whilst still having room for the one crew member within. There followed an effort to redesign the first Ræcc hull to suit this smaller one-man turret, which has worked, although some benefits of the earlier design are lost, notably in relation to hull crew protection.

The result was a vehicle looking remarkably similar to Ræcc and using the same subsystems driveline etc, but having an entirely different internal configuration and hull structure.

This is called Ræcc-R, it represents a moderately compact armoured car the likes of which were common Army equipment until the 1970s, armed with the Army’s favourite medium calibre gun, CTA40, and ATGW.

Vehicle performance is on par with the typical Golf TDI.

Anglo Engineering Rapier-AC

Role: Reconnaissance Vehicle

Design: The Ræcc-R turret (or a close derivative of it) offered itself as a way to revive the remote turret Rapier-A recce vehicle. Keeping to a vehicle crew of two, driver in the hull and vehicle commander either in the optionally manned turret or beside the driver, the vehicle remains as compact as the Rapier-A and maintains that vehicle’s crew protection advantages, but now, of course, allows the commander to operate head-out in the turret.

Use of this turret does, of course, mean the absence of anti-aircraft GW, but there remains the 40 mm CTA gun, the coax 7.62 mm chain gun and two ATGW in a conformal silo, as well as an elevating sensor.

A note about sensors here; the preference is to use spherical units as they maintain a constant silhouette as they pan and tilt, which helps reduce their detection.

But fully gyro-stabilised sensor balls are eye-wateringly expensive – each one way more than the cost of the base vehicle – so a more cost-effective adequate surveillance and targeting sensor solution has to be found.

Assuming an affordable optics solution is found, the vehicle design is sound. Still a work in progress, this is Rapier-AC

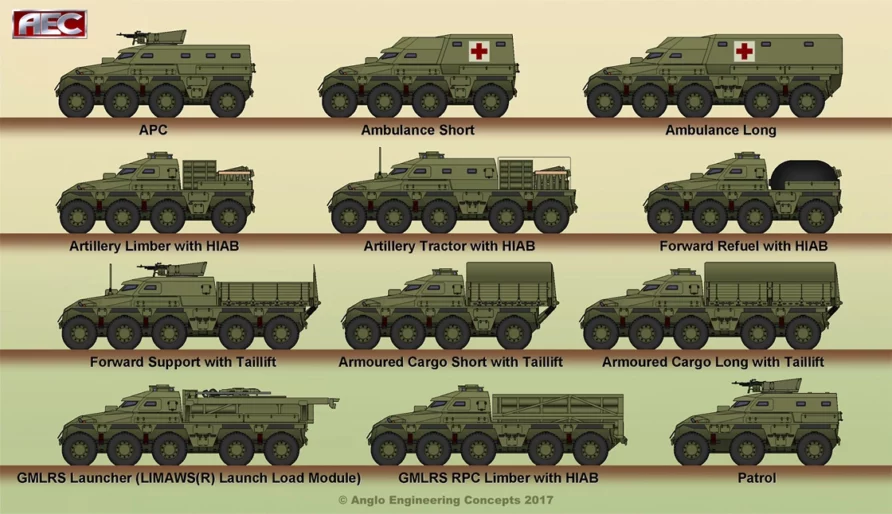

Anglo Engineering Ox

Role: Multi-Role Rapid Reaction

Design: This was the only vehicle in the set that was designed from the outset as a multirole concept based upon an automotive V-hull and a clearly defined and separate ‘mission module’ for the crew and the mission equipment.

However, this is not one vehicle structural design to which role equipment is bolted. Each role requires a separate design of mission module and to support the diverse needs of the role the V-hull may differ in length and number of axles.

The intent is that each vehicle would leave the factory already configured to the role, and that any reconfiguration to a different role would require a return to the factory or at least to third-line workshops.

The design of Ox owes much to FV603 Saracen, a fine design in concept if a little flawed in execution. Not surprisingly, when creating a wheeled V-hulled APC with an engine bay in the nose and crew compartment behind, the result looks like Saracen.

No bad thing; the design was well-considered. The V-hull holds a constant profile for the full length of the vehicle and is the structure upon which all the driveline is mounted.

The mission module sockets into this V-hull behind the engine bay and may take various forms, although each so far considered has a similar driver station.

The following graphic shows some options:

Several variants of the Ox family have been constructed within CAD, showing the variations in V-hull length, number of axles and variations in the mission module.

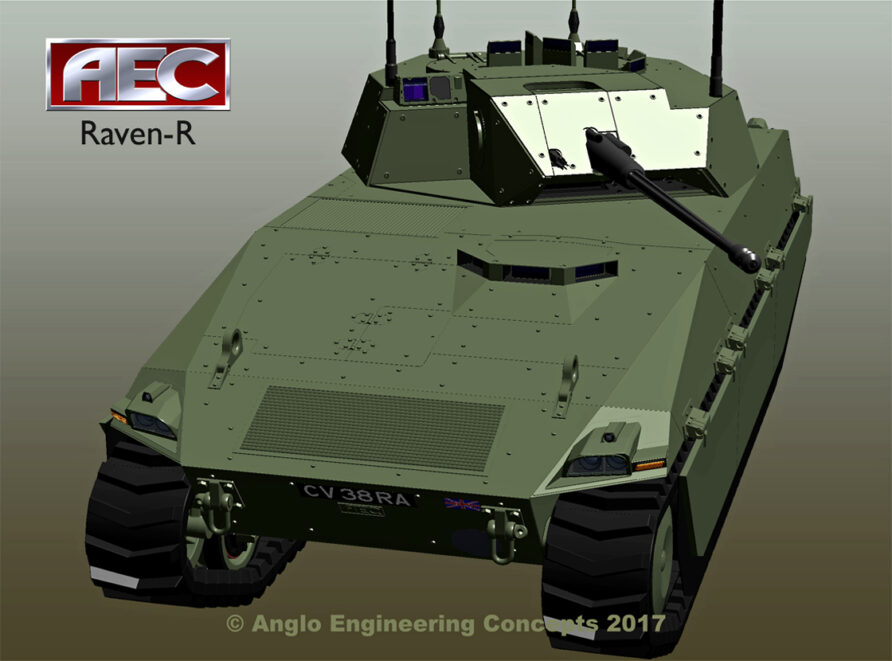

Anglo Engineering Raven-R

Role: Fast Light Armoured Fire Support

Design: Earlier this year, the Raven hull design was reviewed with the Rheinmetall Lance and Leonardo Hitfist 30P turrets; with these more compact units, the hull could be reconfigured, and some radical elements engineered out. This much more conventional, reworked design has been named Raven-R.

Apart from the obviously different turret, it has a forward engine bay besides the driver and a rear escape/resupply hatch, but otherwise shares the original Raven hull’s components, performance, and vehicle role.

What it loses is the unconventional crew protection advantage of the original Raven hull, but its entirely conventional layout would not raise any of the concerns voiced against the original design.

While the vehicle could be constructed at the same weight as Raven, it would be expected that extra blast protection measures would be demanded to offset the higher risk configuration. This would, of course, impact vehicle weight.

While the use of a turret not fitted with CTA40 may prevent UK MOD from considering the vehicle, the use of this hull with either Lockheed Martin UK turrets, Ajax or Warrior CSP, by current assessments is inappropriate due to the long forward overhang in front of the ring which pushes the turret axis far back down the hull.

There would also seem to be significant width of the turret to the right of the centreline in each of the Lockheed Martin designs, which makes fitment to these narrow vehicles far from ideal. It is possible the information available in the public domain is misleading, or indeed has been misunderstood, but until further information is published it seems wise to look at narrower turrets such as Lance or Hitfist.

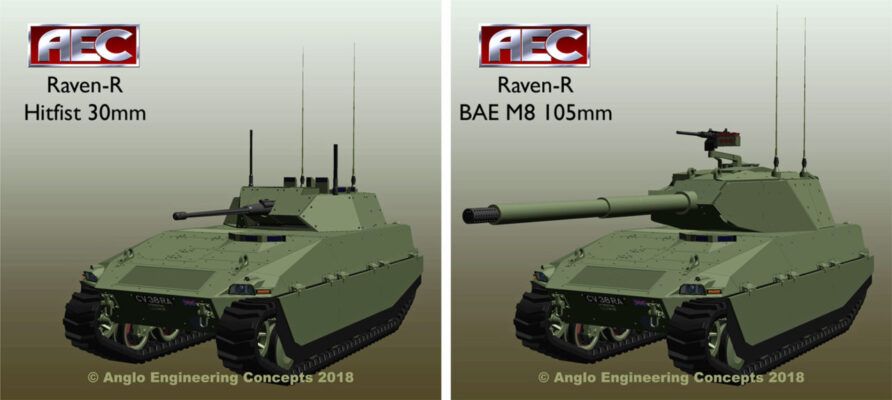

Anglo Engineering Concepts — Large Calibre Turret Assessment

An obvious task is to look at the options for fitting turrets with larger calibre guns. Both Leonardo (ex-Oto Melara) and CMI/Cockerill have 105 mm or 120 mm turrets that are offered for OEM fitment.

A high-pressure gun option would be best, such that MBT armour might be challenged. Initial assessments suggest these off-the-shelf turret options have baskets that are too broad for either wheeled or tracked vehicles of this size; the rings are similarly broad but could be accommodated. It is a shame there are apparently no decent guns being made or marketed in the 60 mm to 75 mm range – such a calibre would suit vehicles of this size well.

But for this task, the turret from the BAE M8 Buford (designed by United Defense) has been assessed for its compatibility with AEC vehicle hulls. This is a 105 mm armed turret with an autoloader, but unlike most of the similarly armed turrets available from the likes of Leonardo or CMI/Cockerill, the autoloader is not mounted in a turret bustle.

In the case of M8, it is a very compact unit nestled below the breech. What this means is that the turret armour is compact and ideally suited to small vehicles with limited hull roof plate real estate. This should be no surprise, as the M8 Buford is itself a small vehicle.

In the large calibre turret marketplace, most turrets are designed for hulls larger than the AEC vehicles. Unusually, the M8 turret was designed to suit a vehicle specifically designed for C-130 transportability; a next-generation Sheridan. It was this design constraint that made the M8 turret the ideal candidate for assessment for its compatibility with the AEC hulls.

The Buford hull and that of Raven-R have a similar width between the tracks. The basket would fit neatly. The depth of the internal volume in Raven-R is greater than that of the very compact M8, but for reasons of internal configuration, the Raven-R roof plate cannot be lowered. However, the same limitations do not apply to the original Raven hull; more of that later.

Looking at the autoloader operation, it would seem most likely to be operated hydraulically. The current Raven hulls are not equipped with hydraulic packs, so this would be a further design update.

But for the basic question “does the turret fit?” the answer is a clear yes.

The size of the turret is illustrated by comparison with the Hitfist 30 mm turret that Raven-R was designed to carry. Big, but not outlandish.

The same turret has been assessed against Raccoon and Ræcc, with the expectation that their steeply sloping hull sides would not allow the M8 turret’s basket to fit. Given the autoloader configuration, it would seem highly unlikely the turret basket, could be reworked to a smaller diameter.

However, the interference in each case is minimal – maybe a 20 mm radius reduction at the basket floor for Raccoon and a 50 mm reduction of floor radius for Ræcc due to its lower hull roof plate – suggesting that it would be possible to engineer a fit.

The hull roof plates of the wheeled vehicles are narrower than on the Raven hulls, which may cause rework if the M8 turret ring is as broad as the armour structure suggests. But again, such changes are possible.

It can be seen that the turret looks larger than the hulls would be expected to carry, despite its compact arrangement. However, even on the taller Raccoon hull, the height of the cupola hatch is within the 9ft (2.74 m) C-130 gauge (just).

Turret weight may be more than desired too, although the complete M8 Buford vehicle was designed for C-130 transport, which suggests the weight of the turret may not be seriously greater than the one-man 40CTA turret that Raccoon was designed to have.

Using the Ræcc hull reduces overall height marginally and moves the turret axis forward nearer to the vehicle midpoint.

The barrel overhang may be an operational irritation, particularly as there would appear to be fairly limited elevation, so running fast over rugged terrain may prove a risky business. But this would be no different to many large calibre AFVs. Indeed, the issue may be more pronounced on the M8 Buford itself, where the turret is mounted on a lower hull but with just as much forward overhang.

This would also apply to the lower profile Raven hull.

So. Back to the original Raven hull reworked for a lower roof plate, named Raven-F. This is to reduce the hull height under the turret ring, which would make for a more stable platform. On the downside, the turret ring is further forward than in Raven-R, extending the barrel’s overhang. But this option does make a better-balanced solution, in proportions that have since the arrival of Centurion been considered the norm for main battle tanks.

Except in this case the vehicle is smaller and because of that, lighter – rough estimate only, but of the order of 16 or 17t. From muzzle to rump it is 8.7m, from ground to cupola it is 2.45m and to turret ring is just 1.435m.

It is little more than the length of Challenger 2’s hull alone; it is just 200 mm longer and 100 mm taller than the unarmed Boxer, and 200 mm narrower. It is also 200 mm shorter and 100 mm lower than the M8 Buford AGS that the turret was designed for, and with a better power-to-weight ratio too.

The obvious question that would be asked is, “Why not just buy the M8 Buford vehicle as it is?” Indeed, if the need was just to buy a tracked 105 mm easily deployable AFV, it would make sense to buy COTS.

But if a 105 mm direct fire capability was desired as just one part of a wider fleet of diverse capabilities, especially if tracked and wheeled were both required, then these AEC hull options make sense.

The commonality is a great advantage.

The OEM option turrets have not been discounted as possibilities and given time and more information than the public domain has to offer, their suitability could be determined. But the apparently comfortable fit of the M8 105 mm turret illustrates such firepower is entirely possible on these compact, high-mobility vehicles.

Anglo Engineering Family Values

Every one of the above vehicles remains within the C-130 gauge for air transport; everyone fits within the UK’s most restrictive W6 rail gauge (for some of the taller vehicles that require the use of Warwell wagons but many could sit on typical flat container wagons).

The 4×4 scout Raðe, the utility Rǽs and each of the Rapier recce vehicles could be moved inside 20ft ISO containers with minimal preparation. These are designed to be easy to deploy in numbers wherever they are needed. Tracked vehicle ground pressure is just 10% higher than CVR(T) at its initial 9t Gross Vehicle Weight, 60% of that of Warrior and 40% of Challenger 2.

Tracked vehicle acceleration would leave most GTIs behind and wheeled vehicle acceleration matches typical family cars, this performance is a result of ensuring enough torque to sustain speed on a 40⁰ climb gradient if ever wheels or track could keep traction. High levels of redundancy within the driveline would offer resilience against damage or component failure.

They are not the world’s most protected armour; they would undoubtedly need to be fitted with RPG protection (Tarian nets would be favourite) and would benefit from being fitted with ABBS VGAM blast protection system; they are not spacious; the turreted vehicles are not armed with 120 mm MBT guns.

Being armoured they are not as light as soft-skinned vehicles and transport under CH-47 would be a challenge for most and impossible for the larger types, but then compromises must be made.

These are simply nimble, small, highly mobile, and reasonably well-protected useful vehicles.

Underlying all the designs is a firm principle to engineering the different vehicle types from common components – common engines and drive systems, common air filtration systems, common instrumentation and controls, for the wheeled vehicles, common suspension, steering, wheels and tyres, for the tracked vehicles common suspension, idlers, road wheels and track-type – with a sharp focus on simple affordability.

Rather than designing a single complex all-encompassing multirole vehicle, individual simpler designs focused on their prime role have been created, but each is based upon the same subsystems and components resulting in very high commonality to ease support burden.

As each vehicle type is freed from the burden of meeting the needs of many roles, they become more compact, lighter, and affordable.

Affordability improves if more types are brought into service as the common support brings benefits in maintenance training, spare inventory, diagnostic aids, and even maintainer currency.

This can perhaps best be illustrated by repeating the earlier graphic of the breadth of UK armour, this time with the above-described AEC vehicles replacing current incumbents:

The shading behind the vehicles shows common support. Consider what such broad common support means; much more accurate spare scaling, streamlined maintainer training, and much-improved maintainer currency, leading to greater maintenance efficiency, lower maintenance cost, and greater vehicle availability. Common support makes sense.

One family of many forms, large and small, tracked and wheeled, this is the sort of joined-up thinking the Army and the MOD needs.

These designs are by no means the limit of possibilities. Given current technology, assume a wheeled vehicle maximum weight of 17t or so, for tracked vehicles that may be increased to somewhere near 28t. This is due to driveline capability, the lower maximum weight for wheeled vehicles down to the larger diameter of wheel/tyre which demands greater torque to achieve acceptable performance.

Note though that the designs undertaken for tracked vehicles have been substantially less than 20t, mostly because this is where the projected UK capability is weak but also because of the self-imposed C-130 transportability constraint. There is no reason why lighter heliportable vehicles could not be designed, as long as lower protection was accepted.

There are challenges not yet met for an amphibious operation, articulation, integration of major hydraulic powered systems (cranes, diggers, winches, lifts) and high recoil force systems (large bore mortar, SP gun), but there are no fundamental reasons why these should be more difficult than in any other armoured vehicle design.

An Echo from the Past

Before Ajax, FRES. MRAV and TRACER, there was the Future Family of Light Armoured Vehicles, FFLAV. Here is what the Alvis team offered for FFLAV:

One view of this offering is to see it in the light of where the British Army is now. In place of VBL, the UK has Panther FCLV. In place of CV90, we have Ajax, remembering, of course, CV90 was the other FRES-SV contender. In place of BMR, we will have MIV.

Was FFLAV visionary? Well, probably not, but it was blindingly obvious good honest robust common sense. So blindingly obvious that thirty years down the line, the original FFLAV solution is roughly what the Army has selected.

There are differences, though. Ajax, as delivered, is far heavier than the 1990 FFLAV version of CV90. MIV is likely to be far heavier and bigger than BMR. And of course, where the FFLAV proposal focused on upgraded and developed CVR(T) and Stormer vehicles, these are now due to retire from UK service.

Taking an alternative view, compare the FFLAV offerings to the AEC family described in the text above. VBL roles are covered by Raðe scout and Rǽs utility. BMR is covered in the same weight range by the various versions of Ox.

Stormer and Rǽde APCs are direct equivalents. Scorpion is matched by Rapier. And while CV90 is heavier than the Raven concepts, there is no technical reason why the Raven driveline couldn’t be used on tracked vehicles up to 28t. And in addition to covering the FFLAV bases there are also the Ræcc and Raccoon armoured cars, and Ram assault gun, and providing driveline technology develops there is the Rival armoured logistics truck too.

And there is VERDI-2 envisioned capability in Ræcc Raccoon and Rapier. And the design approach could deliver many more types of light armour for additional roles too.

The AEC family of armoured vehicles aligns exceptionally well with the FFLAV vision. Except for the one attribute that FFLAV couldn’t deliver – common support throughout the entire range.

Options for Advancing the Anglo Engineering Project

The original design, Raven, was first briefed to the appropriate MOD desk officer late in 2010. Several other briefings have been made since as the text above notes, and the designs have been changed where advice from Users was offered.

The most challenging aspect has been the MoD’s procurement process. Although the MoD has several initiatives in certain product sectors for SME engagement, major vehicle projects tend to be placed only with larger and established companies.

It was suggested at one briefing by a DSTL engineer that would be a good idea to generate a prototype of one of the AEC vehicles to test the concepts, with a view to jointly creating a DSL-owned design for the industry to bid to build (very much as Establishments worked) but he failed to convince his colleagues.

The UK still has a broad spectrum of excellent companies, each expert in their domains, despite the low-volume market for military equipment.

And at all levels too, from stock materials through welding, casting, forging, moulding and fabrication, on through component manufacturers and integrators of specific military systems, to platform level assembly and integration plans to vehicle designers and manufacturers, to complete military product suppliers such as the various divisions of BAE.

The UK has all of this onshore, and it would be perfectly feasible to complete the process through to manufacturing within the UK.

What this means is that there is a broad range of opportunities in how to turn the AEC designs into fielded combat equipment. The following options are, of course, predicated on the Authority and the Army deciding they want this sort of capability.

- Government buys the designs outright and either completes the development of the designs in-house and raises a competitive procurement for primes or manufacturers to bid for the production contract, or raises a competitive procurement for a development and production contract. This would be similar to the process used on Establishment-designed products. The Government has purchased the designs, owns the IP and may change production suppliers as needed. The support contract need not rest with the manufacturer and might be competed separately. This gives the Authority the greatest contractual freedom over the course of the equipment service life.

- Government sets up a collaborative design team, containing Authority, Government scientists, and Army and Industry personnel, all performing tasks necessary for the designs to reach maturity. Somewhat similar to recreating the Establishment’s function, except with the use of Industry players in completing the designs, the IP would need to be shared or purchased. If the latter, this would need declaring at the start of the project so that contributing businesses knew from the outset that whatever they embody in the design would cease to be their IP at the end.

- Industry adopts the designs either by collaborative development or simply by the purchase of the designs by a company of the stature the Authority is prepared to contract, thereafter developing the designs under its R&D budget. The resulting vehicles would be COTS for future competitive procurements; should the Authority choose to buy them, the IP would remain firmly within the company’s ownership.

Each of these options has advantages and disadvantages, but it is probably fair to say the preferred MoD method of standard Competitive Procurement adds significant bid and compliance costs, takes the longest and puts the greatest distance between User and Designer, often allowing User input into the design only at formal infrequent reviews and measuring every User suggested improvement against the contracted Requirement.

It also almost guarantees no commonality either to in-service material or to other projects in the procurement cycle.

It is hoped that reforms at DE&S may provide some future flexibility that reduces bid costs and allows a more integrated and collaborative approach.

A shorter concept to ‘out of service’ cycles would also have significant competitive and industrial advantages

Summary

The AEC concept vehicles described above have all been designed using current technology and were deliberately designed to be as affordable as the technology allows. The Army could benefit from an increase in inventory – more tools in the toolbox – so designing the most affordable solution is in the MoD’s interest.

As such, they would be ideal candidates for streamlined low-cost procurement, where the simple adequacy of the vehicles would be matched by a simple and adequate acquisition process based on free open communication and common teamwork.

It could be revolutionary.

Change Status

| Change Date | Change Record |

| 01/10/2017 | Initial issue |

| 22/07/2021 | Format refresh |

| 20/11/2022 | Minor corrections and updates |

Discover more from Think Defence

Subscribe to get the latest posts sent to your email.

As a civvy this reeks of joined up thinking and cost efficiency.

I’m now crying into my cornflakes!

There is no anti-tank and ground-to-air missile version ?

http://forcesoperations.com/wp-content/uploads/MPCV-600×307.png

Frenchie – the text says Ræcc Rapier and Raccoon vehicle turrets have CTA40, coax machine gun, anti-air and anti-tank missiles. No separate vehicle types with just the one missile system, although clearly such a thing would be possible…

I suspect if you want traction, getting Rapier and the like in to begin with as a CVR(T) replacement is the way to do it. Did you consider hybrid-electric drive and unmanned turrets as options to further reduce weight and size?

wf – not sure hybrid systems save weight – look at hybrid cars; they are no lighter than the mechanically driven models. But they do go a bit faster. As for remote turrets saving weight, surely that depends whether the weapon systems are armoured as ‘mission critical’ systems? The likes of the Raphael 30mm RWS would be lighter but the gun seems (at least on the early models) to be unprotected. If the weapon system gets armourplate then its weight advantage would be down to reduction in overall size only?

Thanks Chris, I did not read carefully, excuse me. This is because I was very interested by the “Raðe”, which is not planned for that and has a design identical to the future VBAE for the little one knows.

https://aw.my.com/sites/aw.my.com/files/styles/news_body_image_1/public/u183517/screenshot0138_1.jpg

Frenchie – cousins!

;-) Chris !!!

Turrets without pilots is practical, but for engines, if you fight in a lost corner of the planet, it is better to have engines not too complex to repair.

Frenchie – agree simple is good; simple means the vehicle crew have a chance of fixing stuff themselves. Unfortunately, because engines have to comply to emissions regulations, and because they need to achieve maximum economy, and because the current engines are made to suit the modern market anyway, it is not really possible to fit mechanically controlled engines any more.

@Chris: hybrid drive weight is much the same, but the ability to eliminate a transmission path and increased flexibility in engine placement has to help. An unmanned turret allows the elimination of the penetration of the turret into the hull as per Bradley TD, allowing more useful internal volume: the latter went from effectively 6 dismounts to 9, all in suspended seating.

http://defense-update.com/products/b/bradley.htm

wf – its noted in the description that the Rapier design with a remote turret came out smaller than the one-man turret version, so yes there is a likely size advantage. But it may not be as pronounced on a low profile (Scorpion-like) hull as the remote turreted Bradley achieved. But possibly academic if the Customer doesn’t want to accept remote turrets.

Fascinating read. Too much to take in at one go. I too was wondering about Hybrid as providing more flexibility and commonality and meeting modern eco considerations. Also the possibility of limited silent movement.

Well, to paraphrase a certain Vulcan – Fascinating ! Don’t see you getting any traction on the tracked light recce, there is no stated requirements after all, but if only we could have all those Ox variants as MIV / MRV-P then the Strike Brigades might not be quite so laughable.

jedpc – no requirement, but still a fast approaching capability gap? Maybe gap is the wrong term as other nations’ armies get by without CVR(T) sized armour, but its definitely a capability that will be lost with CVR(T) retirement. More than a few soldiers (both serving and ex-Army) have muttered that loss might hurt.

Thanks for writing this and doing the work. Looks like some good solid thinking has gone into it, and resisting the urge for shiny new stuff.

Some questions that jump out to me: how much protection do the vehicles actually have? And how often do we expect to operate in threat environments that this is consistent with?

Hannay – possibly delving into detail that isn’t for public discussion there – all design work on military kit here in the UK is governed by export controls so some things have to be kept below the radar. As for the ‘how often would it be usable?’, as noted near the top there would still be heavier armour in service if that’s what the situation requires? Also, there is a school of thought that states the ability to use unexpected routes made possible by light weight small size and high mobility is a method for enhancing survivability beyond the physical protection level (probably a degree thesis in that).

@Chris

Indeed, but those are some of the key questions to answer for a UK acquisition programme. I’m not sure on how best you should try to sell this; maybe addressing a light armour capability gap; or regenerating UK design and manufacture; or playing heavily on the exports and prosperity angle; or all of them

Really needs some interest at 1* or above level to get UK moving I think

Hannay – yes all of those arguments and more. If only the MOD had a defined ‘new ideas’ 1* to go talk to…

How do I go about ordering 200 x Rapier-C?

…As long as it has 30mm frontal and .50 cal protection everywhere else.

Has anyone thought about twin engines?

It must be cheaper to install two 2.0l mass produced turbodiesels?

Diesel-electric then works pretty well split left and right. Either that or use a limited-slip-diff to bind both sides together?

On the weight of vehicles and protection, I think that we decide which missions should be able to make a military unit, and then comes the choice of vehicles to carry out the mission. A rapid reaction force, (I don’t know how to qualify the Strike Brigades) can not work with the vehicles that are planned to endow it, it is impossible logistically.

And I agree that the article is great of course.

Simon – assuming you represent Her Majesty’s Government I would guarantee you and AEC could start discussions right away about development, proving and acquisition strategies…

Unfortunately Chris, I represent Ernst Stavro Blofeld and his aspirations of world domination :-)

You are aware SIMON stands for Subversive Information Manipulation OrganisatioN aren’t you?

Janes, 25 Sept 2017, “Valhalla Turrets reveals new 57mm remote gun system development”. “The Hildgard 57 MRGS uses the 57mm L/76.6 rifled weapon from the Russian S-60 towed anti aircraft gun”. Has a co-axial 14.5mm heavy machine gun. Ammunition handling system will have 33 rounds of 57×348.

That turret on a modernised, upgraded Stormer hull, would be hard hitting & deployable.

Sorry Simon – I’m afraid that’s: No sale!

Frenchie – agreed if there is a need for genuine Rapid Reaction then a Brigade of 35t+ vehicles is not the right resource for the task, and something smaller and lighter is needed. The alternate perspective is if the plan is to only use 35t+ vehicles, then best forget dreams of Rapid Reaction, at least if needing to deploy by air.

@Chris

Maj Gen Chris Tickell as D CAP might be the right place? Turns out Army structure is a nightmare compared to the other services. I’ll try and do some more digging too.

Hannay – thanks, and really good of you to take the trouble to dig the details out; all such potential contacts are welcome.

Having commonality of core components is key to keeping the long term ownership costs of vehicles down , ask airlines who opt for an all Boeing 7** fleet or Airbus 3** fleet.

The turret options are key to the acceptance by the British Army as the feedback shows but adaptability to overseas customers turret options for export orders are equally so as these will possibly be the ‘local’ content they will need to use to sell the design to their own supplier base i.e. votes ( as well as power plant?) .

All in all were we need to be to re-establish ourselves as an armour manufacturer and design supplier of outstanding kit. C2 will need replacing eventually so staring with a solid base of light/medium armour will be a great beginning.

The British Army need to get behind this!

“Raðe” looks like a twin of the Panhard CRAB.

https://i.pinimg.com/originals/fc/73/98/fc739836485eaf5b340c125100f2b442.jpg

“Ox” looks very similar to GeFAS, which utterly shocked me when I saw it on display at Eurosatory. Computer drawings don’t give you a proper impression of the sizes, particularly when there’s a car-like engine hood: Such vehicles are ridiculously huge!

http://i27.tinypic.com/2pozcx5.jpg

SD – thanks for the vote of confidence!

SO – Yes Raðe and CRAB are very similar. I hope both equally good vehicles too. GeFAS though is a very long creature with an exceptionally long nose, so I’m not sure the resemblance to Ox is there. But you are quite right about military vehicle size; the text makes clear the AEC vehicles are within the C-130 transportability gauge, but that still allows up to 2.7m width and height which is not small. The fact that most modern military vehicles exceed these limits shows just how big the average armoured vehicle has become.

JH – just seen your comment about the Bofors 57mm turret – really quite interesting, and they have evidently made prototypes. Worth further investigation. Thanks for the pointer!

One thing to consider regarding extant turrets is that the cost, for the most part, is not in the structure. You could aim to use the same sights, electrical and electronic systems gun control equipment and guns that have been proven to work together but enclose them in a new structure.

For a general purpose missile turret you could consider the Thales multi mission system that can run Starstreak and lightweight multirole missile at the same time.

Very nice article and some good designs. Two things I would like to bring up though.

Why have you never looked at the Toutatis unmanned turret that the French developed for the 40mm CTA weapon system? I know it lacks guided weapon systems and you have been keen to include them into designs. But the UK has been more than willing to field turrets without missile systems on vehicles in the past and even currently. Such a turret may offer the same advantages as the Lance and Hitfist turret, while still retaining the 40 CTA weapon system with the rest of the fleet.

Secondly, I think the Ram design, while it certainly brings a good amount of protection for an assault vehicle. The need for active suspension systems and the gun being the same 40mm gun as the rest of the fleet, it would be a rather costly vehicle with a very small niche to fill. I assume a 90mm Cockerill or larger gun can not be fitted due to their size or lack of autoloader on designs.

With that said the L9 165mm gun is of rather compact size and well suited to the task of assault gun. Or is it still too large due to the need of a dedicated loader?

mr.fred – note the words under Rapier-AC about the cost of EO/IR sensors. Huge expense. But with the incredible numbers of digital camera sensor chips (in every phone now) capable of high definition imagery in poor light conditions, and solid state uncooled IR cameras, and the anti-shake digital post processing in a lot of dedicated digital cameras, you have to wonder if a perfectly adequate sensor ball couldn’t be created at a tiny fraction of the cost of gyro-stabilised stirling engine cooled high spec FLIR balls? Weapons will though remain expensive. Can’t help that. If I recall correctly the combined cost of the Rarden gun, the Spire sight and the turret’s Rotary Base Junction was almost the same as the cost of the rest of the Scimitar vehicle. But I might be wrong there.

JH – a note about the Hildgard 57 MRGS you referenced – while interesting I can’t imagine use of a Russian AA gun using Russian ammunition in any British Army vehicle. Not for the foreseeable future. But something to bear in mind where export potential is concerned.

Some things

JohnHartley

Janes, 25 Sept 2017, “Valhalla Turrets reveals new 57mm remote gun system development”.

never die (haven’t sees the Janes piece… does the new one in it look anywhere close to this old one?)

http://i58.fastpic.ru/big/2013/1029/f3/7c7f4d57e55a05fb991a607e996e65f3.jpg

Taurevanime – Toutatis was investigated and has influenced the designs a lot. It was a sharp and well thought out design. There is of course no reason why it couldn’t be fitted to an AEC hull if that’s what the customer desired. As for the Ram vehicle, its very much a niche thing, really valuable when its necessary but quite pointless at all other times. It has had less design effort so far precisely for that reason. As for bigger calibre weapon, the overall length of the vehicle is much the same as the Raven, and a barrel length over 3m would become a bit of an issue, let alone the size of the breech, the recoil motion and the ammunition stowage. One of the CTA40 round natures (GPR-PD-T) is described as capable of penetrating more than 200mm of reinforced concrete – this seemed a reasonable amount of punch for starters. But if a customer wants this sort of vehicle but with a bigger gun, it can be looked at.

@Chris

Re the FLIR requirements COTS solutions are available . A marinized FLIR , gyrostabilized , with a very broad operating range is offered by

http://www.flir.com/marine/m400

SD – I used as an example device a full mil FLIR sensor (more accurately two of them) on the CTA40 turrets. I had the opportunity to directly ask their price a month or so back and was fairly horrified at how much they’ve apparently gone up by since I’d last checked the price (although that was years back). The challenge is to get the right sort of optical performance and the necessary aiming stability at a price that doesn’t multiply the vehicle price several times over. Sounds like a Uni project to me.

I had noted the comments in the article about the cost of electro optics. It struck me as odd that these were identified as the sole high cost items in the vehicle when There are numerous other systems that are going to be up there as well. Stabilisation and gun control equipment, for example.

On the cost of the electro optics, I’ve no doubt that the proliferation of sensor technology will, eventually, bring costs down, but simply slapping a smartphone into a tank is not going to work as well as people imagine it might. If it were so easy to make a low cost sensor system, wouldn’t people have done it? For pure observation anti-shake would be ok, but if it’s part of your gunnery system how do you account for it when directing your gun? Gunnery requires very, very accurate systems.

Then there is latency, safety integrity levels and resilience to the armoured vehicle environment, which is fairly unforgiving.

Which sets up another thought. If the design IP is let, shared or whatever, to a party, who then have to do a bunch of work to make the system work correctly and safely, who owns the IP at the end?

mr.fred – I accept lots of systems have the potential to be a lot more expensive than you might at first imagine, but seven-figure price tags for each sensor system struck me as steep. As for shared IP, such issues have rumbled around the technological industry for a long time now. Personally, with a taxpayer’s hat on, I favour the system the UK once used almost universally, where the Gov’t paid for stuff to be designed (either in-house at Establishments or out in industry as funded development or Cost-Plus) and then there was no argument – the IP was owned by Her Majesty’s Government and it could licence manufacturers as it felt fit.

I’m rubbish at posting links, but see if this works (for the 57mm Valhalla turret).

http://www.janes.com/article/74361/valhalla-turrets-reveals-new-57-mm-remote-gun-syste

I kind of agree: the IP should reside with the person who paid for it.

Although with increasingly optimised and specialised designs required to obtain advantage on the last generation, in some cases you are reliant on manufacturers IP to make the design work.

And optics are really, really expensive. From what I’ve seen you can tell the difference. Whether that difference is worth the cost or not can only be answered by a whole heap of operational analysis that the MoD don’t seem to do anymore.

Little question; isn’t anybody else irritated by the gimballed sensors in the 3D images? Those sensors would barely have horizontal vision (not really if there’s camo material on top), and in many directions the dead angle against crouched infantrymen might be dozens of metres!

Less so because there is a statement about how the roof mounted ones are on short masts and as such are presumably seen here in their recessed states. I assumed it counted for all of them.

I was more bothered about the lack of protection for any of the sensors, but that seems to be a bit of a trend for modern fighting vehicles.

SO – sorry you are irritated. The text explains the sensors in the turret top are on elevating platforms = the images show them retracted where they would be best protected in transit. The ones set in the turret front, like those in the same position in Lance, the Puma E8 and the Kongsberg MCT-30 remote turret, are for targeting so the right place for them is at the height of the gun and as close as possible to it to minimise parallax error. Pointless having a targeting sensor that has a better field of view than the gun has an arc of fire.

JH – thanks again for the link. If you check this page: http://www.valhalla-turrets.com/calliber-57/ and scroll down past the Hildgard RWS with its russian gun you will find the larger Odin remote turret with the Bofors 57mm naval gun. I think for western powers the Bofors option would be more acceptable?

mr.fred – correct deduction. I considered dropping the upper sensors into a protected housing but the elevating mechanism cannot collapse lower so it added more height than I thought sensible. The sensor can of course be rolled to protect the ‘windows’ leaving the back of the ball to field twigs and the occasional stone. But these are, as has been stated a few times, concepts that in discussion of an interested customer would be modified as necessary.

Ræcc – the telescopic mechanism would need to be in or right next to the breech, which looks misplaced.

http://u0v052dm9wl3gxo0y3lx0u44wz.wpengine.netdna-cdn.com/wp-content/uploads/2017/10/170828AEC-RavenR-RaeccR-Rade-OxMLRS-OxAMB-1a1120.jpg

The tracked vehicle on the right appears to be too narrow. There’s a golden middleground for track contact length to gauge ratio. A too slim ratio like this will make pivoting and turning generally difficult. The increasingly compact powerpacks allow for much shorter vehicles than the 1970’s generation (see Leclerq) , so this ratio is against the trend.

The Ox appears to overemphasise protection. The ratio between cost of the vehicle and actual payload seems to be horrible. It would replace near-COTS trucks that got uparmoured (RHA + cheap slat armour) cabins in some roles!

The tracked vehicles appear to use continuous band tracks. Segmented band tracks are much better, as they allow for much quicker and easier repairs and for carrying a spare segment for repairs after a hit. No such spare segment is mounted anywhere.

There aren’t enough smoke projectors. Raven seems to lack them entirely.

The panoramic mirrors on Ræcc and Rapier look wrong. The user’s head would need to be so close that he would bump into the mirrors all the time.

SO – I’m sorry the description text is not more clearly written. To take your points in order:

The sensor ball on the front of the turret does not elevate because it is the gun’s targeting sensor and as the previous response to you stated it has to remain at the mantlet trunnion height and as close to gun axis as possible to do its job. The sensor on the turret roofplate does elevate.

It is noted in the text above that L/C ratios have been central to the design of the tracked vehicles. The ratio is close to the theoretical ideal, and on a par with Warrior. If the CAD graphic fails to give that impression then that’s beyond my control. Perhaps the impression is caused by the vehicle configuration; these are light armour and like CVR(T) the track edge is in line with the outer edge of the armour. Many armoured vehicles have tracks inset in some cases by best part of half a metre, often a result of years of added applique armour along the flanks that has increased the hull envelope width far more than the length.

Ox protection is on a par with the other wheeled vehicles. Is it over-emphasized? Well, as the point was to design high mobility well protected armoured vehicles, the emphasis has to be there. As for arguments over cost of purpose-designed armour vs. up-armoured cargo trucks, you are right they have to be determined to be good value in terms of their operational utility for the customer to decide to buy. Perhaps the question is better aimed at the Armies that are buying expensive wheeled armour – why for example did Bundeswehr buy 400 Boxers when it could have bought much cheaper armoured cab Rheinmetall/MAN SX and HX trucks? Clearly they thought there was value in the more expensive option.

Continuous vs. segmented band tracks? Yes there are downsides to continuous bands. I took pains to put those arguments to a supplier of both types of track, continuous and segmented, and was in turn presented with some sound but unexpected downsides that relate solely to segmented track. The choice is far more balanced than it seems at first sight. Those arguments might have been slightly influenced by the manufacturer’s potential profit advantage of the one track type over the other but the engineering rationale was sound. I’m not going to broadcast their products’ weaknesses because that would not be good ethical practice.

Smoke grenade launchers – in most cases I have put a pair of launchers on the vehicles. As the text pointed out for Raven-R, this was a design put together for COTS turrets, the two mentioned being Rheinmetall Lance and Leonardo Hitfist – I chose to make a CAD model of the Hitfist turret because there is more public domain technical data for that. The technical data does not show a ‘standard’ smoke grenade discharger fit although the Polish turret has a set on the left hand side only, six tubes angled to cover both left and right arcs. I could have fitted what are pretty much the UK standard grenade dischargers but as the text points out without a CTA based turret the chances are the UK wouldn’t take on the vehicle, and as it seems each nation has its own favoured smoke grenade system there seemed little point bothering to second-guess what that might be. Yes the vehicle would need smokes; that I didn’t model any on a COTS turret already fielded with smokes fitted hardly proves the design deficient. As for total numbers of smoke grenade launchers on the rest of the vehicles, with the exception of Ajax which now has four off four-tube launchers, the UK fielded vehicles have until now been fitted with one four-tube launcher per side. I checked the current state of Megatron, ATDU’s Challenger 2 reference vehicle used to check out latest design modifications and it too it seems has just one launcher per side. Again, if the demand changes then the number/type of launchers can be revised without issue.

Periscope positioning – you may be right. As with other aspects in the design these things can be amended when a customer engages. Bear in mind these designs are deliberately as small as possible so they are not palatial inside; it is far easier to design oversized products than minimal sized ones, but there are penalties if sharp concentration on constraining dimensions lapses. As I recall, on the subject of periscopes and their positioning, in CVR(T) the driver’s scope has a foam rubber pad fixed above the glass for the driver’s head to rest against – the manufacturer’s data for the driver sight shows the design eyepoint approximately 40mm from the glass. And it is arguable that reducing the distance between head nominal position and obstruction (in this case the sights) reduces the velocity the head can reach before smacking into them, possibly making the more confined space less damaging in reality.

I trust the above text has helped put some of your concerns to rest. There is no such thing as perfection in design, the best that can be achieved is the optimum set of compromises to suit the priorities of the requirement. Some customers might prefer a different balance of compromises. But for the constraints I imposed on the designs, the compromises made have justification.

Chris

The Bofors 57 turret looks good, but would the extra ton+ weight over the Valhalla, be a problem on an evolved stormer hull?

JH – you may note from the selection of vehicles that the one variety not present is an IFV. When it comes to high mobility light armour, my view is that firepower and infantry transport are best separated into focused platforms. The APC prime role being to avoid getting in harm’s way as far as is possible so that the troops may be deployed safely and fighting fit where needed, the armoured car (for want of a better role designation) deliberately putting itself in situations where it can take action to protect the APC and its occupants. One APC/Armoured Car pair probably capable of transporting as many dismounts as two similarly sized IFVs, but having more operational flexibility, the ability with the dedicated armoured car to mount a more capable array of firepower than could be perched atop a high roofed hull, and as a consequence ending up with two vehicles of lower profile than the ‘APC + turret’ IFV. So, the question of putting a heavy turret on the roof of an APC is not one that is foremost in mind. The potential to fit the heavier Bofors turret (or indeed an AEC turret fitted with the Bofors gun) on either wheeled or tracked low profile hulls does strike me as something deserving of consideration.

As for the use of Stormer itself, that’s something that lies in BAE’s court. Obviously I believe the designs I have come up with offer many advantages over Stormer, but that’s far from saying the CVR(T) based vehicles are useless. They have proven useful platforms and over the years have improved with upgrades born of operational experience. Maybe though after 50 years its time for a newer concept to pick up the challenge.