OK, so I realise RORO ramps and link spans aren’t a secret, or even interesting, but how many people have heard of them?

In any expeditionary or disaster relief operation, the likelihood is we will be sending vehicles and stores by ship. Those ships will normally be of the Roll On Roll Off type and equipped with a folding ramp of some sort for vehicles and cargo to be loaded and unloaded quickly, without the use of dockside cranes or other infrastructure.

A RORO ship can access a port using either conventional reinforced surfaces are more link spans.

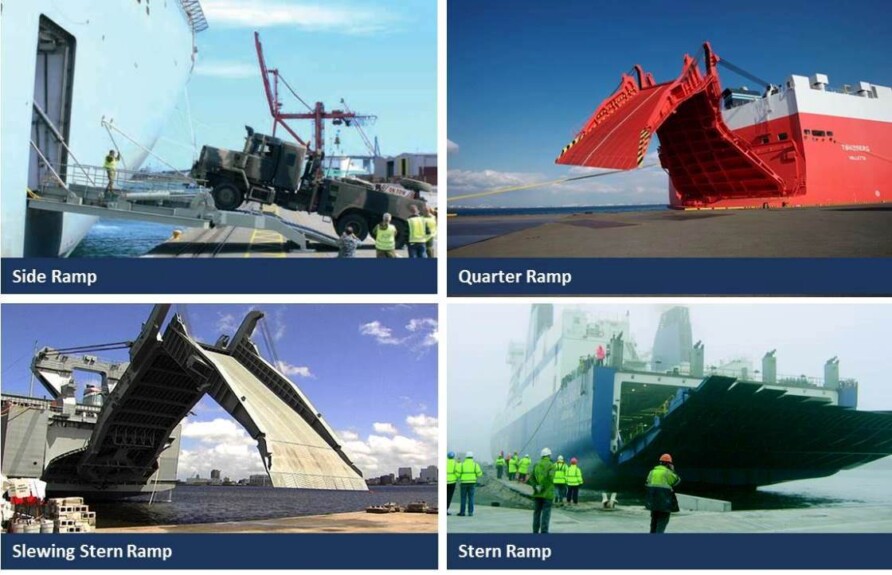

Different types of RORO ramps place restrictions on how and where they can be used. A stern ramp, for example, can only be used if the ship is moored stern-in.

Each of these different types of ramps has advantages and disadvantages. The UK’s Point class strategic RORO vessels only have side and stern ramps, for example.

The US T-AKR class of fast sealift ships use a slewing stern ramp to enable them to discharge from the port side, starboard or centre, a very flexible, although heavy and expensive, solution.

The image below shows Anvil Point moored side-on with a small pedestrian ramp used for access, but vehicles cannot be offloaded like this.

Ports that have a high tidal range may need alternative arrangements that allow ships to load and unload regardless of the tide or their ramp configuration. The first method is to use a ramp or slipway, this is the simplest and lowest cost and therefore most common for smaller and lower-volume ports. They can be of earth or concrete construction and fitted with mooring bollards, fenders and connecting roadways.

These may be aligned parallel or perpendicular to the shore to allow for different types of ship and mooring arrangements.

The other method is to make use of a device called a linkspan.

A linkspan is an intermediate device that evens out the different heights of the ship’s cargo deck/ramp and the quayside.

The mechanical support linkspan uses hydraulics to raise and lower the ramp onto which the RORO ship’s ramp is landed. The support housing is secured to the seabed using piles. Tidal range and different ship deck heights can be compensated by raising and lowering the deck, and the more complex types have multiple ramps for fast loading and unloading of vehicles and foot passengers simultaneously.

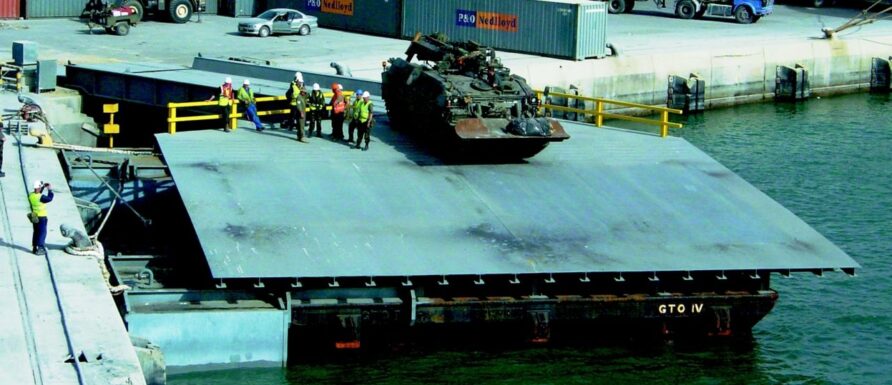

A floating linkspan falls and rises with the tide, the main structure being buoyant. Some ramp height variability can be accommodated using tank ballasting, and they are usually of single-deck construction, although some multi-deck floating link spans are in use. The landing area and tank create a large water plane, resulting in good resistance to traffic loads.

They comprise two main components, the landing platform (typically incorporating the flotation tank) and the connecting roadway.

Floating link spans tend to be simpler than mechanical link spans, as is evident from the image above.

The recent use of a linkspan in a UK defence context is that for the build-up in Kuwait in 2003 before Operation TELIC. As coalition forces were being built up in Kuwait in January 2003, port space was at a premium at the main port of Shuaiba. There were many vehicles to offload from chartered RORO vessels, and the berths available for 24×7 operation (No 11 and 12) had no slipways or RORO link spans available. The port also had a wide tidal range

Some kind of floating linkspan would be needed.

527 Specialist Team Royal Engineers (STRE) were tasked with sourcing one and consulted the Engineer and Logistic Staff Corps (ELSC), a network of senior civilian engineers. E&LSC is a little-known organisation comprising senior executives of sixty British logistics and engineering organisations that retain military rank but have no military duties or pay. They exist purely to provide expert advice, often characterised as ‘all rank and no file’

After consulting E&LC, the Royal Engineers turned to Transmarine in Newcastle, the same company responsible for FIPASS in the Falkland Islands. They faced a tough challenge, the linkspan had to be in place by the planned arrival date of 24th February 2003. After examining potential options, Transmarine decided to purchase a pontoon in Bahrain and design and fabricate the superstructure and bridge deck in Dubai. The final linkspan consisted of a 28m by 14m steel pontoon with two additional 4m × 7m flotation sponsons permanently fixed to the pontoon.

The superstructure and hinged 17m bridge deck could be set at an angle to accommodate ships with stern ramps and different tidal ranges. The assembled construction was secured to the quayside by a series of tensioned rope moorings. It could accept the heaviest and largest military vehicle loads, including Heavy Equipment Transporters (HET) towing a trailer with Challenger 2 Main Battle Tanks and variants. Difficult and awkward cargo such as Chinook helicopters could also be accommodated.

The whole thing from start to finish cost £1.2 million.

Op BROCKDALE was the recovery of British Forces from Iraq.

Perhaps whatever comes after the Point Class Strategic RORO service will specify the more flexible slewing linkspan like the T-AKR ships, or we might retain some kind of floating linkspan in service.

Or not.

Read more (Amazon Affiliate Link)

Discover more from Think Defence

Subscribe to get the latest posts sent to your email.

Nice article! as a terminal planner this has been very educating to me. Thank you

Interesting read. Amazing engineering in it all. Thanks for posting it!