The accusation that the British Army is wedded to massive tent cities, resistant to imaginative thinking and meaningful change, is unfair and incorrect.

Whenever you discuss deployed command posts and headquarters one is left with the impression that everyone is acutely aware of the issues. British Army officers are professionals, they are not blind to recent conflicts where loitering munitions and UAS-guided artillery play havoc.

No one is sitting on their hands, there is plenty of work going on to experiment with different concepts, all designed to improve agility and survivability, by HQ ARRC, 3 DIV, 1 DIV, the Land Warfare Centre and many others.

That said, I do get the impression this is disjointed across the Army, it is being done at the unit level, without an overarching programme to manage outputs and budgets, exploiting external expertise to develop standards.

I am probably wrong on this and more than happy to be corrected, not everything that happens is visible from the cheap seats outside, after all; meaningful change doesn’t always need DSTL and a multi-million Pound contract to happen.

What are we talking about…

Terminology changes, I think deployed headquarters below Brigade size are now called Command Posts, but forgive me for using the terms interchangeably.

People with experience and expertise absorb information and collaborate to make decisions, communicating those decisions via appropriate means.

They might not look like offices for knowledge workers but that is exactly what they are.

With the warning that I am 99% unsighted on what is going on in the Army on this subject, a few semi-random thoughts.

Change Drivers

Change is driven by numerous sources but they all point to a need to be quicker, more efficient and streamlined, and adapt to the threats of pervasive surveillance leading to near-real-time targeting by complex weapons, loitering munitions and even old-fashioned artillery.

As younger people, so used to device portability and constant connectivity, move into command positions, they will bring their expectations with them. There is no point whinging about the younger generation (I generally detest that stuff), we must adapt to them, not the other way around. That said, streaming some banging tunes whilst posing for an Instagram post might not necessarily be the best use of the electromagnetic spectrum.

Every single person in a CP/HQ has several support personnel; drivers, cooks, guards, signallers and many more. The bigger an HQ the more personnel it consumes, every one of these must be drawn from a fixed overall force size. Any reduction will have a ripple effect, remove one person from an HQ and you potentially remove one or more from the support pool.

The form must follow function, bloated HQs are a result of process and risk, no one gets up one morning and just decides to double the size of a Brigade HQ. This means any conversation about HQ/CP agility must ALWAYS start with outputs, processes, and inputs, set against a backdrop of risk management.

Go too far though, and you diminish resilience.

Clearly, there are benefits from HQ/CP size reduction, but this is easy to say, very difficult to do.

Distribute command functions across multiple nodes, and you will potentially improve survivability, but you increase the demand for connectivity between them. More connectivity might actually mean more detectability and a reduction in survivability.

Open Systems Standards

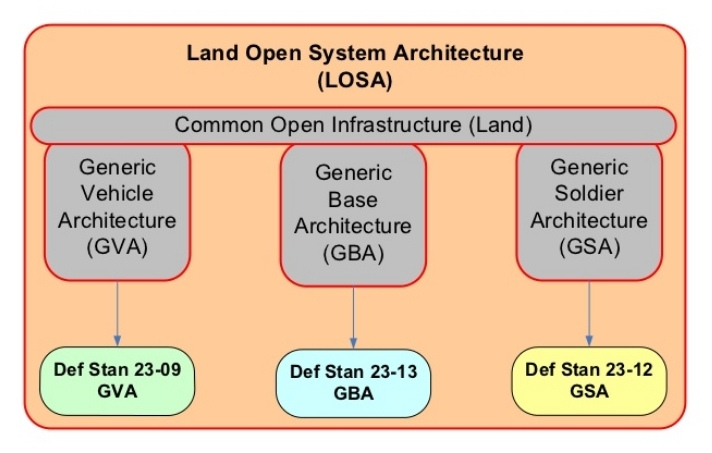

The smartest thing the MoD has done that hardly anyone has heard of is the Land Open Systems Architecture (LOSA).

Many might have heard of Generic Vehicle Architecture (GVA) but this is a subset of LOSA.

For vehicle-based command posts, especially those in A vehicles, GVA absolutely applies, a German Boxer command post variant is shown below.

But there does not seem to be a Generic CP/HQ Architecture.

This might be a gap and one which seems ripe to exploit as a method of driving standardisation through the organisation, reducing duplication and capturing good practice.

Standards develop over time, especially if we own them.

GVA has taken some time to mature and be adopted across NATO, but the work the MoD wisely did many years ago is now beginning to bear fruit.

I hope we can do the same with HQ/CP’s.

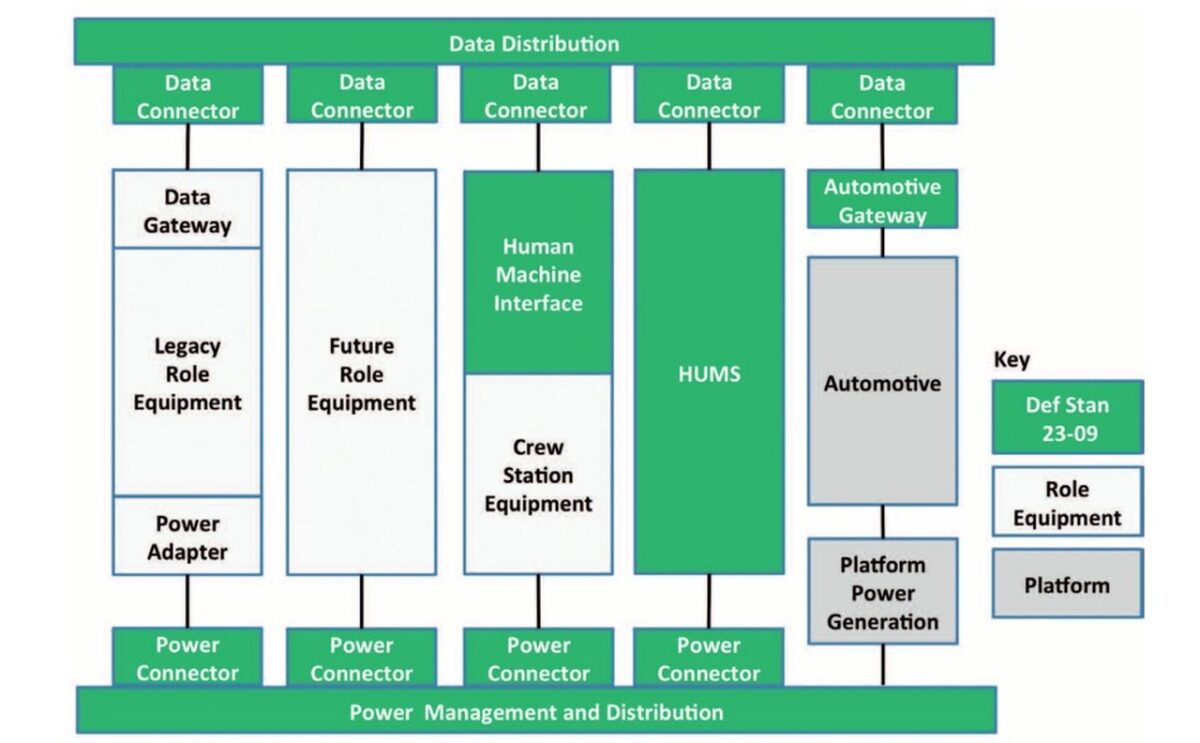

Technical Infrastructure

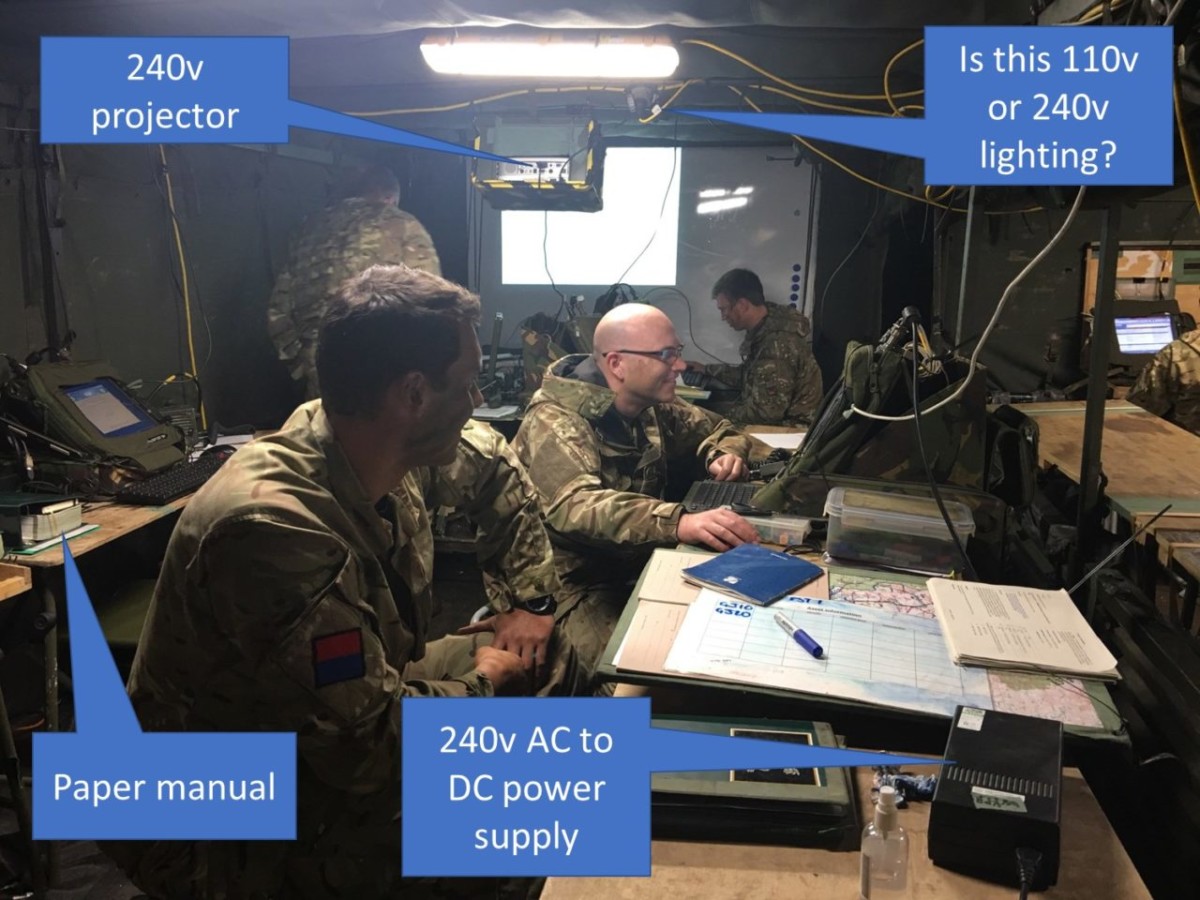

Look at any pictures of deployed HQ/CP’s and you will always see 240v devices.

Look at any pictures of deployed HQ/CP’s and you will always see whiteboards.

Look at any pictures of deployed HQ/CP’s and you will always see a projector.

Look at any pictures of deployed HQ/CP and you will always see laptops and chargers.

Look at any pictures of deployed HQ/CP’s, and you will always see thick manuals and aide-mémoires.

We need to challenge all these things.

I am going to pick on 1 RIFLES to illustrate my point (sorry)

Before that though, this Tweet from the CO is an absolutely brilliant example of the improvisation and experimentation I was talking about earlier in this post, the kind of thing that the British Army gets accused of not doing, I hope when people talk about the lack of ideas and experimentation they look at this. They used a pair of 6-tonne MAN SV trucks parked side by side to form a workspace, quick to set up and move, and all using existing equipment, fantastic.

You can glean a lot from just looking closely at these images and start to think about those challenges described above.

Look at most others, and you see the same things, this is not an isolated point image that it would be unfair to extrapolate from.

When you start thinking about the power demand, the inefficiency of stepping voltages up and down, and the resultant heat load that has to be managed, you can start to see how viewing a CP/HQ in terms of power management is crucial. The more power they consume, the more diesel they will need for generators, the more diesel they consume, the bigger the logistics burden, the more heat they generate the more difficult it is to mask. Diesel generators are noisy and produce their own heat, if we want to avoid being seen and heard, this matters.

So my question comes in two parts…

Do we genuinely understand what is driving power demand in deployed HQ/CP?

Do we have a programme of works to dramatically reduce it?

Can we use -48v DC?

Anything below 50v is generally considered safe, an important factor in deployed locations that are often wet and might be subject to damage.

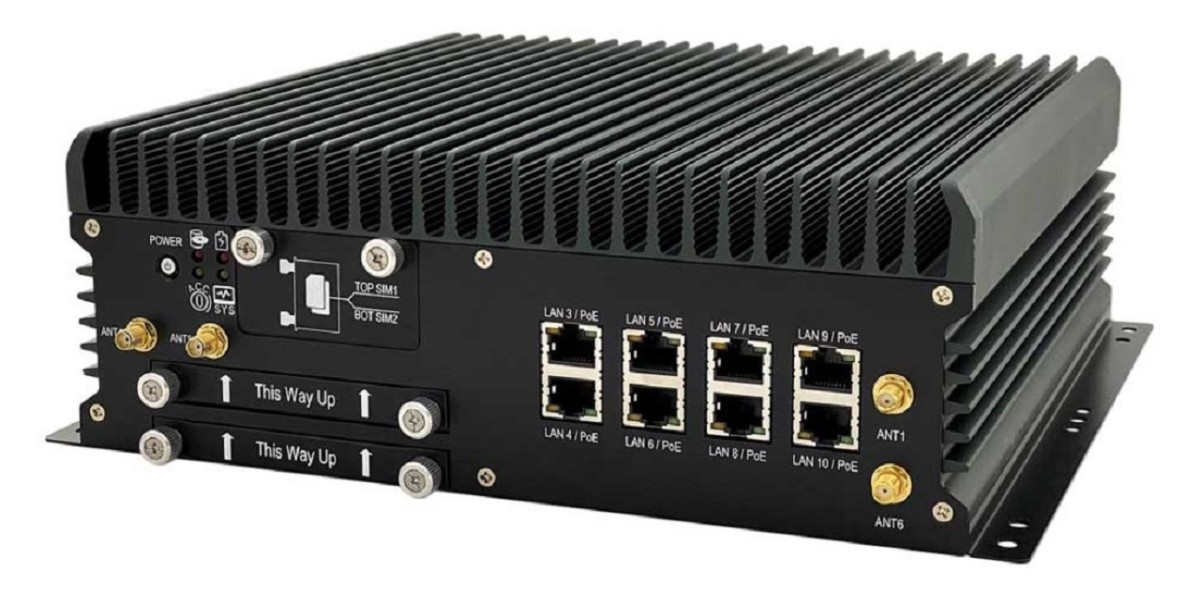

-48v DC is widely used in the industrial and telecommunications sectors for switching equipment, servers, and edge computing devices. Whilst there are disadvantages in terms of conductor size/weight/cost, there are many advantages. Whilst industrial computing and network devices that use -48v will certainly be capable of handling the physical environment, there be additional standards compliance and certification activities to be completed before they can be used in a military environment.

Most dedicated military equipment in this field tends to be 16-32v, designed around 24v vehicle power systems, but as vehicles move to 48v, this will change

Adopting Solid-State Drives (SSD) will also bring power reduction benefits, with manufacturers like GRID in the UK and many others offering them across their range of specialist defence computing devices.

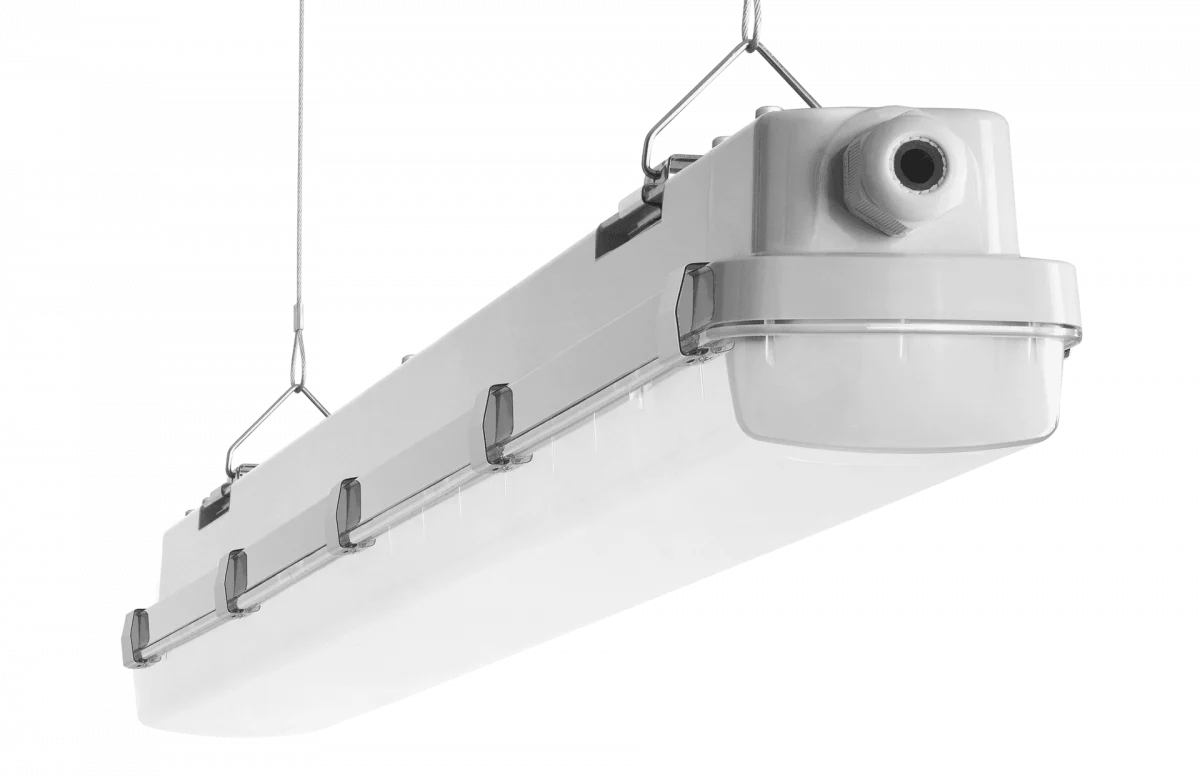

Many LED track and industrial lighting systems use 48v DC.

With the increasing prevalence of hybrid vehicles, 48v is also becoming more widespread as an auxiliary device power system, with -48v DC air conditioning and heating devices now available. -48v might eventually replace 12v/24v systems in vehicles, and it could be worth looking at the viability of adopting it as the single DC power system for HQ/CP environments.

Power over Ethernet and USB Power Delivery (USB-C)

USB is now a universal interface for many devices.

USB has evolved from a data interface capable of supplying limited power to a primary provider of power with a data interface. Today many devices charge or get their power from USB ports contained in laptops, workstations, docking stations, displays, cars, airplanes or even wall sockets. USB has become a ubiquitous power socket for many small devices such as cell phones, tablets, portable speakers and other hand-held devices. Users need USB to fulfil their requirements not only in terms of data but also to provide power to, or charge, their devices simply, often without the need to load a driver, in order to carry out “traditional” USB functions.

The USB PD3.1 specification now supports 240w power delivery at voltages up to 48v DC.

The USB PD3.1 specification defines a choice of three new fixed voltages: 28V (above 100W), 36V (above 140W) and 48V (above 180W) joining previously defined 5V, 9V, 15V and 20V fixed voltages. A new adjustable voltage mode enables a range from 15V to one of three maximum voltages (28V, 36V, or 48V) depending on the available power allowing the device being powered to request specific voltages to a 100 mV resolution. Safety requirements for products in the 100 – 240W range are also more stringent than lower power products and are defined by the applicable safety specifications dictated by the regulations for each country where the products will be sold.

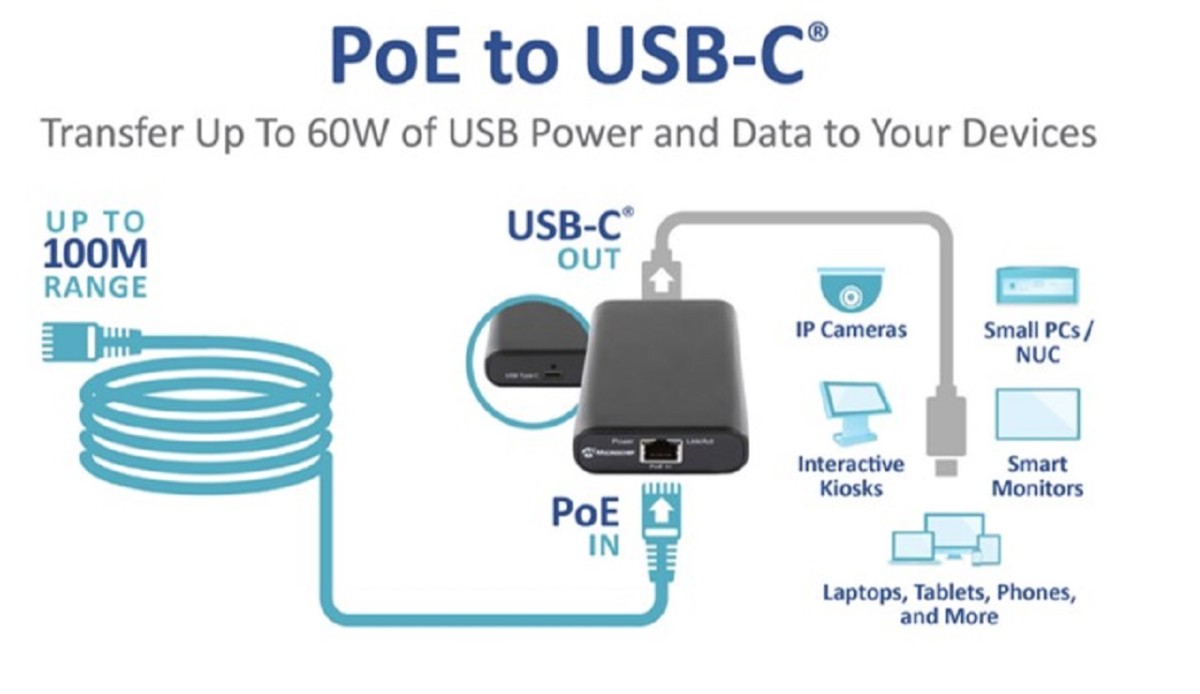

This opens up several possibilities like powering screens and computing devices via Power over Ethernet, another possible means of removing 240v completely from the HQ/CP environment.

Using Power over Ethernet to deliver both networks and USB-C Power Delivery would be an interesting experiment in cabling and power management.

The network and power network for user devices would be the same, instead of plugging a big power brick into a 240v socket to turn that 240v into 24v (plus heat), we can use the humble RJ-45 connector to deliver DC power and network connectivity. This might also provide opportunities for low-power devices such as thin clients and integrated monitors/PCs.

Do we need a projector to show graphics, maps and status boards, I cannot answer that question, but this brings us to large-screen display technology. Would a 40″ rugged display with an input voltage of 19v work better than a 240v heat pump we usually call a projector, and could be powered directly over structured cabling with a POE endpoint?

It is also worth investigating the rapidly expanding professional power pack market for solutions that avoid running generators.

Ecoflow is a good example, with a range of products to cover multiple scenarios.

e-Ink Displays

Most people are familiar with e-ink or e-paper, who doesn’t have a Kindle?

Beyond e-readers, they are increasingly used for retail signage, warehouse rack displays, and travel information at bus stops.

Whilst refresh rates and colour depth continue to evolve, current e-ink displays are persistent, have extremely low-power requirements, excellent readability and clarity, are viewable from wide angles, non-emissive and very rugged.

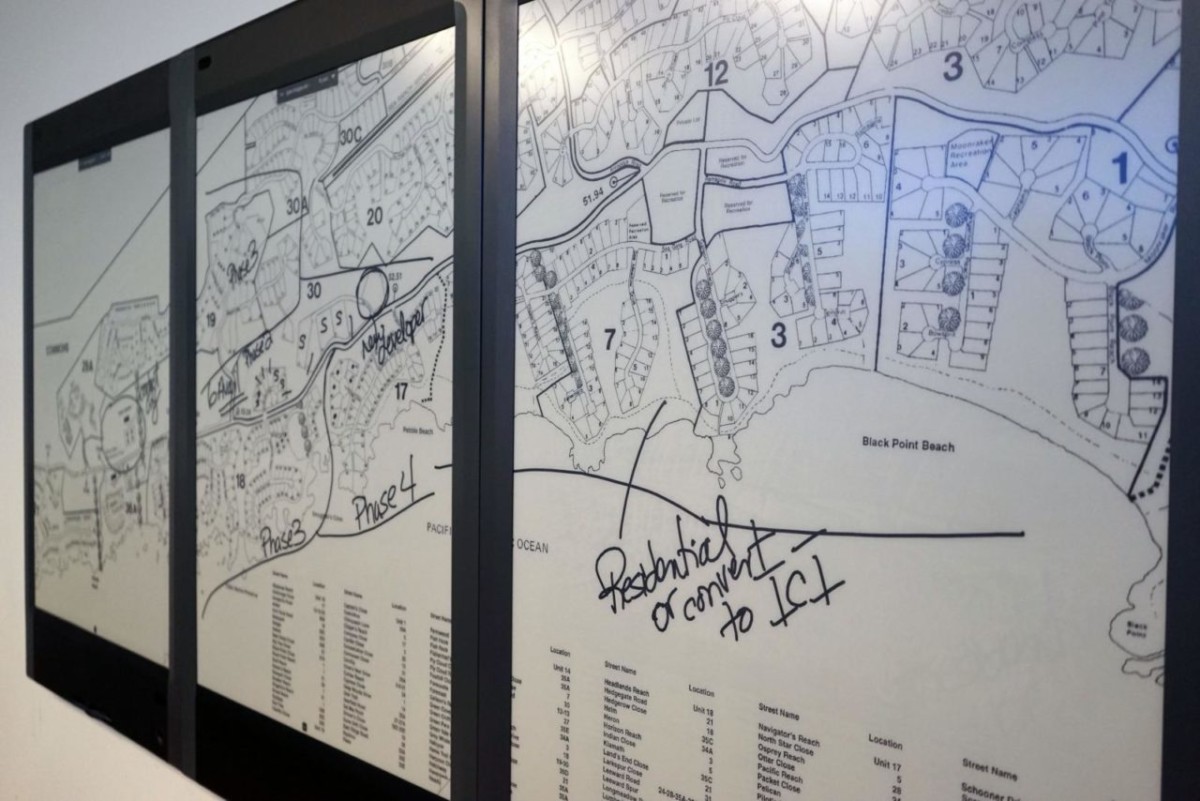

Linking them to command and control, inventory, telemetry and other systems across a CP/HQ network would allow them to act as status boards, location trackers, timezone clocks, alert states, timers and almost anything that doesn’t need high-definition colour and fast refresh rates.

They can be interfaced and driven from low-power computing devices like single-board computers and run from small batteries.

Some large devices can be tiled together to make massive displays, some can even be used as a whiteboard.

We take information from computing and telemetry systems, and transpose that to a whiteboard, making sure to use the correct pen, is this the best we can do in 2022?

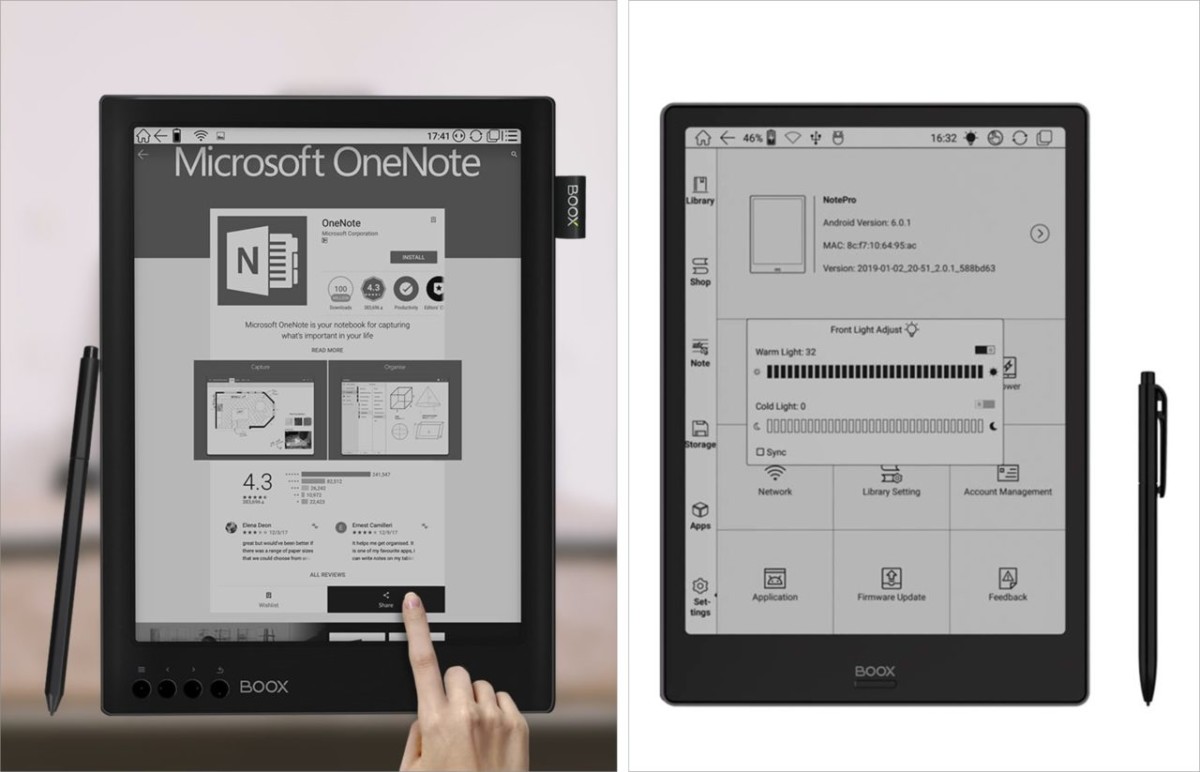

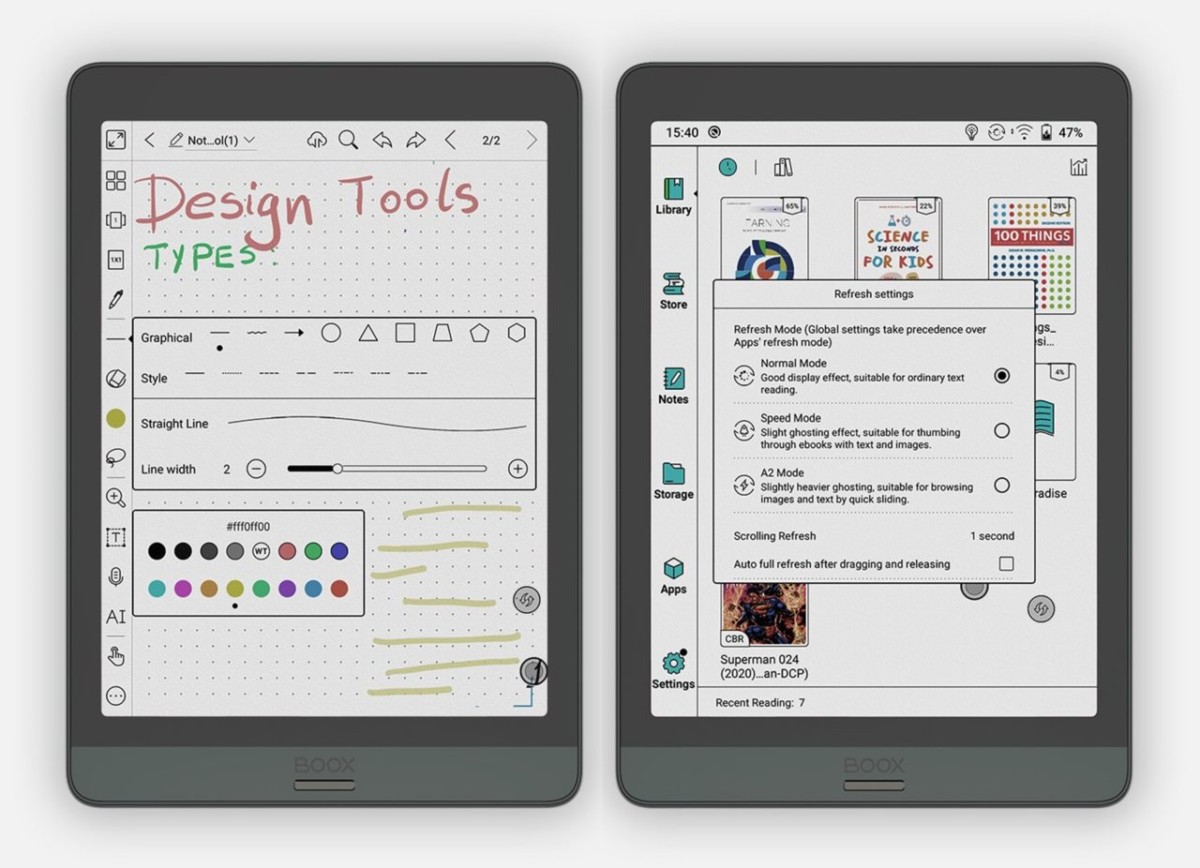

e-Ink Computing Devices

With many defence workflow applications built around form filling on screen, I also wonder if some laptops could be replaced with an e-ink tablet.

Unless there is a need for full-motion video or high colour depths, we should be looking at the low-power potential of e-Ink tablets.

Using a document management system, the latest TAM or manual could simply be distributed to thousands of devices quickly and easily. No need to print, no need to carry 4-inch thick binders, who knows, maybe one day we will be able to replace the Nyrex folder and Moleskine notepad?

Power Tool Batteries

As I discussed in this post on commercial power tool battery technology, we should pick a platform and expand its use beyond engineering and artisan trades, into the HQ/CP environment.

Want a coffee or a NATO Standard, easy, issue these.

Fancy something cooler, or a warm pie, is also easy.

A bit warm, put the fan on.

I don’t want you to think this is a thinly masked advert for Makita (and have deliberately avoided their battery lighting, which is excellent) but by thinking about power across the whole of the HQ/CP environment, we can achieve improvements in safety and resilience, simplify cabling and reduce power demand (and we all know the benefits of that).

Human nature means someone will always want to bring a 240v device, so just issuing an edict to ban them won’t be effective, we can recognise this problem and adopt something like a power tool battery solution.

Silent Running

Once we have reduced the power demand, there is potential to run a CP/HQ on battery power between moves, using vehicle charging whilst in motion to prepare for the next stop.

Adopting power tool batteries is a quick and simple means of providing USB power to portable devices, especially those with USB-Power Delivery or lower power demand like those e-ink tablets and displays described above.

Modern defence communications use a significant amount of power, so low-power user devices are not a panacea, but they are certainly contributory. For large HQ/CP environments, it will be extremely challenging to move away from diesel generators, but there is certainly a lot of work ongoing to make it happen, the more we reduce demand, the easier that job becomes.

Before reading on, would you mind if I brought this to your attention?

Think Defence is a hobby, a serious hobby, but a hobby nonetheless.

I want to avoid charging for content, but hosting fees, software subscriptions and other services add up, so to help me keep the show on the road, I ask that you support the site in any way you can. It is hugely appreciated.

Advertising

You might see Google adverts depending on where you are on the site, please click one if it interests you. I know they can be annoying, but they are the one thing that returns the most.

Make a Donation

Donations can be made at a third-party site called Ko_fi.

Think Defence Merch

Everything from a Brimstone sticker to a Bailey Bridge duvet cover, pop over to the Think Defence Merchandise Store at Red Bubble.

Some might be marked as ‘mature content’ because it is a firearm!

Affiliate Links

Amazon and the occasional product link might appear in the content, you know the drill, I get a small cut if you go on to make a purchase

Ergonomics

Let’s look at two ends of the scale.

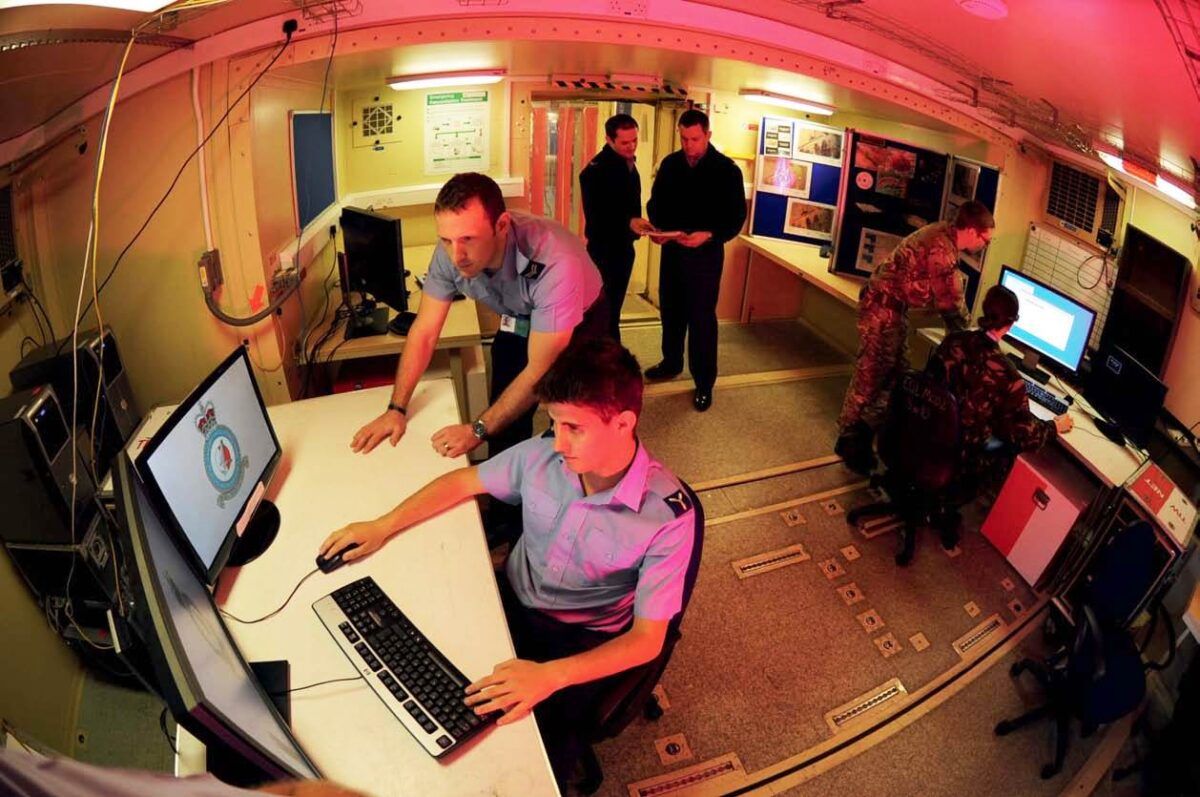

HQ ARRC is about as big a deployed headquarters as you are going to find…

And inside people are working on computers

Watching someone present a slide deck in a meeting room.

Teams working in a multi-monitor cluster with a large display board.

In short, all the components and activities of a modern office.

At the other end of the scale, we have a manager delivering a presentation.

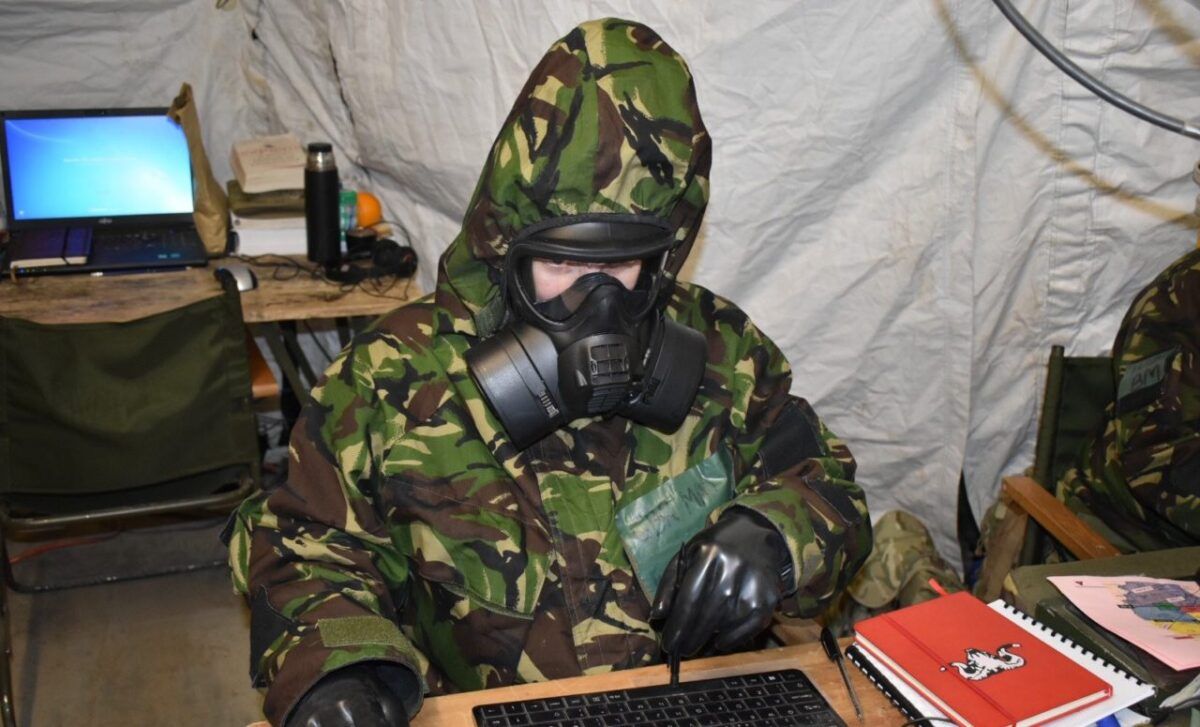

And an information worker dialling into a conference call

Whilst an agile squad listen to a scrum leader talk about the latest sprint.

I am being relatively playful, of course, but the command post and tactical HQ environment are no different to any modern office. That environment differs in the simple fact that most modern offices don’t have to move at the drop of a hat and don’t have a group of people with a very particular set of skills, skills acquired over a very long career, skills that make them a nightmare for people like, I am sure you get the point!

What do you see in all those pictures above?

A 6ft (1.83 m) folding wood table and Land Rover chair. Look at that second ARRC picture, someone bending overlooking at a tiny screen, crowded desks and hardly any space, and this is the largest deployable HQ there is. Where there are external monitors, they look tiny. Cables taped to the floor with hazard tape and extension cables.

None of this says modern office, and the word ergonomics seems to be a stranger to any Army HQ or command post environment.

You are probably laughing at me now, I get that, but study after study that looks at human performance in the built environment tells us that the environment and ergonomics have a large part to play in effectiveness.

Modern tactical headquarters and command posts, therefore, have the almost impossible task of creating a well-lit, spacious and modern work environment that meets societal norms and expectations (younger people moving into command positions) whilst being deployable, mobile, as invisible as possible, and survivable.

These lads don’t need to worry about light discipline.

And these people certainly don’t have to concern themselves with cam nets and enemy loitering munitions

There are no easy answers, are there ever?

Just dialling into yet another bloody Teams call.

But we should think about ergonomics, the impact on the performance of poor ergonomics, and build relevant metrics into any emerging Generic HQ/CP Architecture Standard.

Look at the image below, large clutter-free desks that are a neutral colour, large screens, decent chairs, plenty of space, someone gets it.

That someone is the RAF, with their TARDIS vehicles (they are called that, Tactical Air Reconnaissance Deployable Imagery System)

This brings us to shelter design.

Shelter Design

I am going to start this section with a great challenge from Ryan

https://twitter.com/RyanNoordally/status/1155517147931652101

Do read the thread, a more than fair challenge.

Ryan concludes…

Wellington’s army, pulling a trailer with a Landy across Salisbury Plain and wasting a copious amount of my and my det’s time building tents, moving furniture in, using map boards and pins, remoting UCDs, UDTs and ancills and digging a very misnamed LFG? Why?

Why indeed?

To start at the smaller scale, an RE Squadron or RA Battery CP, 3 or 4 people, Land Rover FFR and a 9×9. This setup seems to endure, resistant to any kind of change or improvement. Just making a quicker-to-deploy tent would be a big improvement, yes, we would have to consider light leakage and durability, but ‘batwing’ style shelters are hardly rocket science.

They take a few minutes to deploy, plus some time to add wall panels

Watch the video for just how quick, and compare that to a 9×9.

Although quicker than a traditional tent, you still have to move the tables and chairs, whiteboards and technical infrastructure, adding time and inconvenience. Even at this scale, there are more integration solutions.

Weatherhaven in the UK (among many more) offer a trailer-based solution called the Tactical Redeployable Expanding Container Configuration – Trailer (TRECC-T)

It is small and light enough to be very transportable, able to be carried on a single 463L pallet or underslung by a Merlin or Chinook, for example. It takes 5 minutes to deploy and has enough space for a couple of people to operate. They also offer a 463L pallet-based version of it.

Larger versions are also available, fantastic products

Light commercial vans with integrated workspaces are another option.

And yet another challenge to the notion we are not trying these things

Of course, we don’t have light commercial vans in service beyond the White Fleet, but the potential is obvious, and if you want more space for a briefing area, those smart people at ICC Offroad in Germany have an idea for you.

Rolling Unit in Estonia is another interesting company with some intelligent products.

There is no shortage of options for this type of 2-6 person shelter, trailer or vehicle-based, there are all out there from a wide range of manufacturers.

Moving up the scale to ISO Container solutions, the choice becomes even wider. I should probably do a separate post on these because there are so many, expanding or non-expanding.

We already use these in various forms, for the RE mapping teams or REME instrument technicians.

The non-expanding types offer the possibility of command on the move, this example being the Elbit Rhino

Go even larger, tent cities are already in service, and stick out like bulldogs you know what, so why not blend in with the type of surrounding most likely to be found in many urban areas? A Zap Shelter is a good example of this, already used in defence, just not for HQ/CP’s. They are surprisingly fast to build and very scalable.

More importantly, they don’t look exactly like a deployed headquarters, park some engineering plant and a couple of dozen pallets nearby, and they blend into almost any industrial environment.

It would be good to compare build rates for one of these compared to the image in the post header.

This is also an area where it looks like one part of the British Army is not talking to the other half, look at the Deployable Engineer Workshop (DEW), with its containerised air handling units and expanding containers, could this be the basis for a decent large HQ?

If we are concerned about blending in, a few of these might not be an altogether bad idea.

Simply put, there is a tonne of shelter options, each with varying degrees of integration, but it is this integration I want to address in the next section.

Before reading on, would you mind if I brought this to your attention?

Think Defence is a hobby, a serious hobby, but a hobby nonetheless.

I want to avoid charging for content, but hosting fees, software subscriptions and other services add up, so to help me keep the show on the road, I ask that you support the site in any way you can. It is hugely appreciated.

Advertising

You might see Google adverts depending on where you are on the site, please click one if it interests you. I know they can be annoying, but they are the one thing that returns the most.

Make a Donation

Donations can be made at a third-party site called Ko_fi.

Think Defence Merch

Everything from a Brimstone sticker to a Bailey Bridge duvet cover, pop over to the Think Defence Merchandise Store at Red Bubble.

Some might be marked as ‘mature content’ because it is a firearm!

Affiliate Links

Amazon and the occasional product link might appear in the content, you know the drill, I get a small cut if you go on to make a purchase

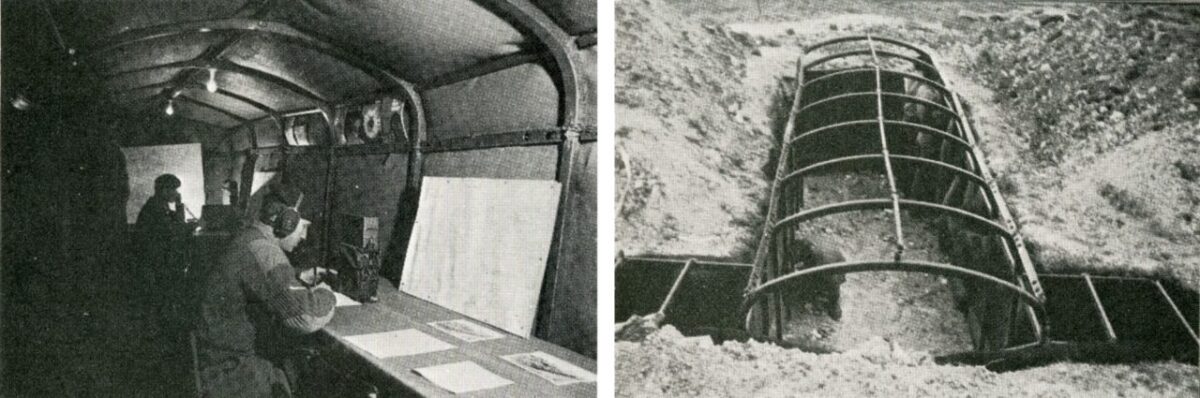

Exploiting Spaces of Opportunity

The main problem with those highly integrated solutions is vulnerability consequences. Integrate a costly command and control facility with a truck and should that truck have an engine problem or flat tyre, your expensive command and control facility is immobile and potentially useless. It also means that you are wedded to the truck or container. Should you want to exploit an Aldi supermarket or warehouse, block of flats or barn, you might be unable to.

Looking at all of this, think we need to break the link between what is happening inside a shelter and the shelter itself.

This means we need everything inside a CP/HQ to be moveable, demountable, able to be carried by two people and no more.

Great if we can palletise to make things quicker.

But in general, small building blocks should be the rule, certainly for the smaller CP/HQ’s

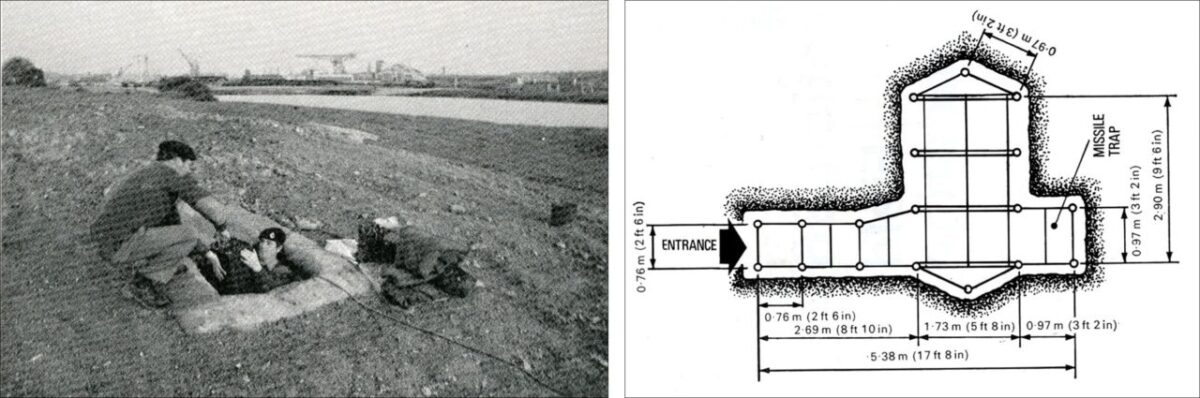

Like this.

This is one of the biggest take outs for me, we should have clever people with clever stuff, doing their clever things in ANY environment.

And that includes a hole in the ground.

This is why I am less keen on those very complex integrated shelters, resilience, and options.

Packing Efficiency

You didn’t seriously think you were going to get through a Think Defence post without some mention of pallets and containers, did you?

As we start to develop a more systems-led and standardised approach to CP/HQs, a consequence is the ability to optimise packaging efficiency to improve deployability. There are quite a few of these types of solutions, but these images give a good overview.

Load up your stores inside the G10 frame system

Get your friendly forklift driver to put them inside an ISO container

Secure for transport

Load

And at the other end, do the reverse.

Cam Nets

Cam nets and poles are a perennial problem, time-consuming and frustrating.

In an urban context, does the traditional setup work?

Wondering if there was a better solution and just for a bit of amusement…

And a reply!

Probably not as mad an idea as one might think!

Have a look at the Saab Barracuda Camosphere for something with a bit more street cred, and certainly something more like.

As 32 Regiment Royal Artillery have recently shown, concealment in an urban or semi-urban environment needs a lot more thought than just stringing a cam net up.

Summary

We spend enormous amounts on vehicle and communications programmes, but how much do we spend on HQ and CP spaces?

They are the fulcrum on which every single operation pivots, yet we still have expensively trained officers stooping over wooden desks in Land Rover chairs, using technology that someone from the nineties would recognise.

They will be mercilessly hunted by the other chaps in almost every operational scenario, and yet we are still using diesel generators and old-school cam nets.

How much do we understand, across all units in the Army, what the power demand is?

Do we have a standard non-operational model environment for each level that people can experiment in, try new things, and then roll them out across everyone?

Are we exploiting the best that modern technology has to offer?

I genuinely don’t know the answer to any of these, but it strikes me that we need to spend more and do more in this area.

Civvies pay thousands for this :)

Further Reading

https://cove.army.gov.au/article/electronic-warfare-threat-command-post-perspective

Discover more from Think Defence

Subscribe to get the latest posts sent to your email.

perhaps more a question than a comment, I presume all electronics “leak”EMF, do these command posts/HQs have shielding for this? looking at the vehicle solutions again presumptuous, these would/could have built in faraday cage ??

What about COLPRO? Yes I know CBRN isn’t as trendy as UAVs, and loiter munitions, but if you don’t factor it in then it isn’t a fully deployable HQ. Also why does ARRC’s CP need to be on the battlefield? We remote UAVs from RAF Waddington to conduct strikes in *insert country name*, why does the uber high up command team need to be there too. Saves manpower if they can work out of a building in Gloucester. Top Brass could always do Zoom/MS Teams Orders Groups, or hologram in! It would reduce footprint and tactical concerns, but would mean the One Star was able to check if the ‘boots fitted, and the mail got through’.

Excellent post as always. Taking the obvious and then reviewing the arches that support. You challenge the status quo. In this case the power source for a CP/HQ. These are all heat signal and potentially, obvious, physical give aways. I love the idea of everyone getting high tech, my fear is that we lose “low-tech’ skill sets.

Ukraine is a good example, moving from electronic and digital comms for ‘defensive’ locations to land line.

My gut is that we still need the armed forces to have a neolithic capability as back up, whilst making them cutting edge, technologically.

Perhaps we shouldn’t sell off all of our old kit, mothball and train groups o it, just to keep them current. After all the T-64 is now working the Donbas, the Douglas Skyraider worked well in Vietnam and the 4T UBRE was able to dish the goods in GW1.

Solar, wind generators and portable LiFEPo battery’s should be a consideration as well maybe ? Not just during vehicle charging but in situ for a CP. Will cut fuel usage and allows for more reliable comm’s.

One of the most interesting and important of your posts. Having been on the staff of divisional fire-centres, I have always been concerned about the piles of equipment, antique telephony, paper maps, folding stools, and the rest of it, and, principally, the wonderful target such a tent city represents. In this case (only) thank you Mr. Putin for ringing the alarm bell for the rest of us.

I'm glad to see you have included the ECOFLOW power pack

As many of the fundraisers for the Ukrainians use them

Very popular!

Helping to charge and power up vital equipment