Trailers, storage, and stowage are essential parts of any quad bike ATV replacement and as an integrated solution, they should ideally be acquired jointly under a single programme.

Quad bikes are not used to transport bulk supplies; mixed loads of ammunition, water, fuel, tools, batteries, radios, defence stores and other military equipment will be the norm, plus in some cases, casualties, and additional personnel.

This diversity means that any trailer or on vehicle stowage options have to be flexible, avoiding over specialisation.

On Vehicle Stowage

Conventional quad bike ATVs are generally fitted with a front and rear mounted cargo rack, allowing the drive to secure them using ratchet straps, bungee cord or small cargo nets.

After market solutions include soft storage bags and hard plastic or metal boxes.

These might be useful, as could more integrated solutions such as modular systems like Rotopax fuel and water containers.

Molle panels could be fixed to the racks to improve stowage flexibility, but in general, the simple front and rear rack on most ATVs provide a suitable approach for the majority of use cases.

Securing longer items such as missiles or crew served weapons is difficult, and in most cases, these would be moved to a trailer, but fold out racks such the Quadcrate Butterfly could be added for very little cost.

With a more defence focus, LV-TEH in Latvia makes a similar range of storage rack fittings.

Quadcrate also makes a dog carrier that can also be fitted to the trailer hitch.

As the threat from uncrewed ground vehicles increases, a quick deploy post and wire barrier could use a quad ATV mounted barbed wire dispenser. Arguably too specialised, but civilian markets can be exploited for defence requirements

Thinking about storage options upfront, and the means of securing onto the ATV body and load racks, is a simple way to maximise value from any replacement programme for relatively minor cost and time overheads.

Trailer Basics

Most quad ATV have relatively modest payload capacities on their front and rear racks, typically no more than 100 kg.

A trailer therefore allows the vehicle to move heavy and bulky stores.

Dimensions and Payload

In the previous post on ATV replacement options, I split the contenders into those that could be despatched to ground using a double Container Delivery System (CDS) skid board, and those that were too large.

If it applies to the vehicle, it also applies to the trailer.

A one size fits all approach could work, where that size is bounded by 96″ long, 48″ wide, and 83″ high, or 2.44m × 1.22m × 2.1m, constraints of a double CDS.

The width of the trailer is likely to be somewhere near the width of the quad bike itself, with most of them already within the 1.22 m CDS width in any case.

Height is unlikely to be a significant problem, so the decision rests on length.

The Logic trailer bodies are approximately 1.4 m long, which is OK for Bergens, jerrycans, ammunition boxes, and demolition stores. However, pickets are 1.8 m long, infantry bridges and ladders tend to be around 2m long, a stretcher is 2.2 m, and a typical 9m telescopic radio mast is between 2 m and 2.5 m when collapsed.

I discuss pallets later in the post, but a 2.16m × 1.0m, 1,120 litre Dolav ACE SL2160 could be used for pre-packed unit stores.

The LADX Easibridge system uses 1.7m long components.

An ISO shipping container is approximately 2.33 m wide, and a typical quad bike ATV is between 2 m and 2.4 m long.

This means that a trailer with a load bed length of between 1.8 and 2.2 m would be ideal, depending on which of the various items of equipment listed above were to be included.

The coupling assembly adds additional length, but there are folding options available to make transport easier.

The Logic trailers have a folding coupling assembly, shown in the image above, in the raised position.

Collapsible designs are available, but these are mostly used to reduce storage space, not transport.

A dedicated ‘airborne trailer’ could be a realistic option within the context of a wider purchase if other users wanted something longer.

Configuration

For simple trailers, the configuration options are relatively limited, the load bed can sit above the wheels, or within them.

A flat load bed with wheels underneath maximise clear load space, but they raise the centre of mass and can reduce mobility. For a given width, with wheels outboard designs have reduced load bed space, but have a lower centre of mass.

A stepped, or inclined trailer body design aims to get the best of both.

The in-service Logic SMT 171/172 trailers are good examples of a stepped body design.

The in-service Logic trailers use the same wheels and tyres as the in-service Yamaha quad ATV, neat. Any new design should do likewise.

Double or single wheels per side would be largely determined by payload and stability requirements. The example below shows a trailer with a flat load bed and a double wheel suspension design.

Integral ramps and prop stands could be added if needed, easier to integrate with a flat load bed design as above.

There is some relevant UK legislation for trailers, mainly that they have to have a braking system if the total weight exceeds 750 kg. Larger quad bike ATVs tend to average at about 600 kg max towing weight and tongue weight, and the in-service Yamaha Grizzly 450s have a maximum towing weight of 600 kg.

The in-service SMT 172B ATV trailer has an unladen weight of 243 kg, with a maximum gross weight of 450 kg (207 kg payload) at 60kph, but this is reduced when carrying a stretcher to 40kph, although the gross towing weight is increased to 600 kg or 407 kg payload.

Any new trailer design would have to meet or exceed these.

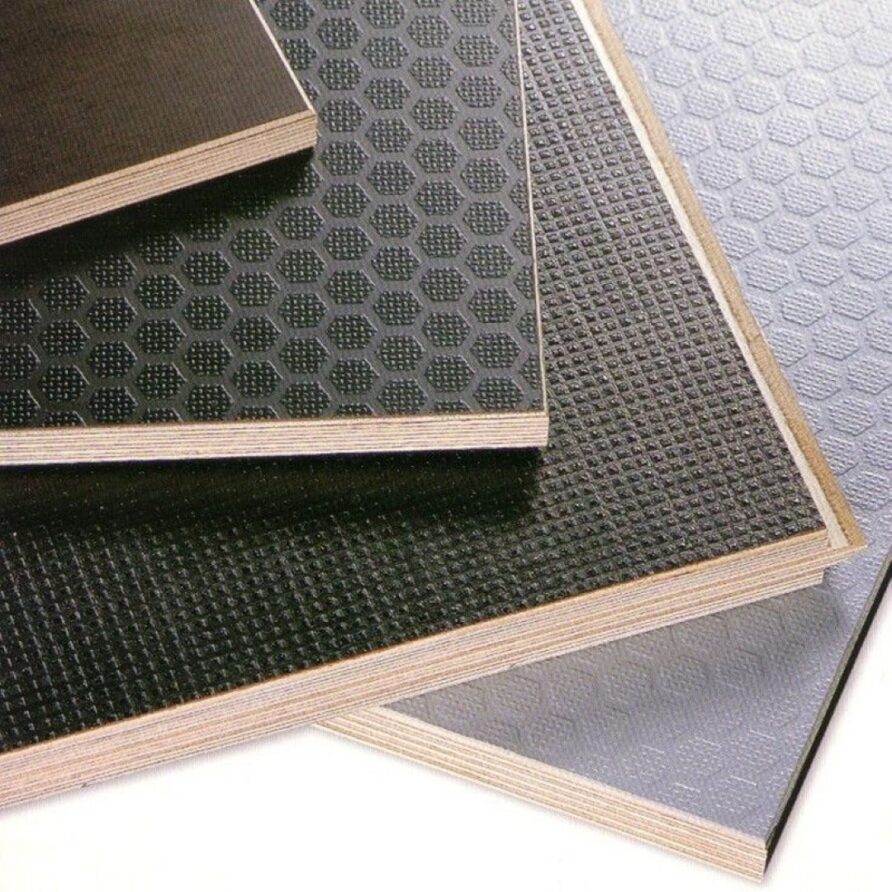

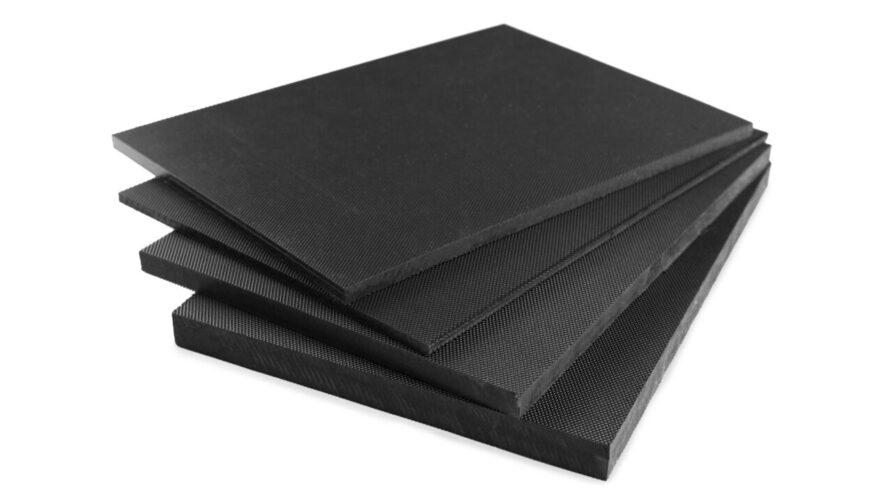

Construction Materials

Most trailers will be made of galvanised steel for cost and durability reasons, either of a monocoque design or using square or round tube.

Some variation exists for load bed materials.

Phenolic plywood with anti-slip embossed coatings like those from Wisa are used for trailer and horsebox floors, van floors and other similar uses.

Stokbord is a proprietary product that uses recycled plastic.

Other sheet products that also use recycled plastic are increasingly available, likely much more durable than plywood, although they are pricier.

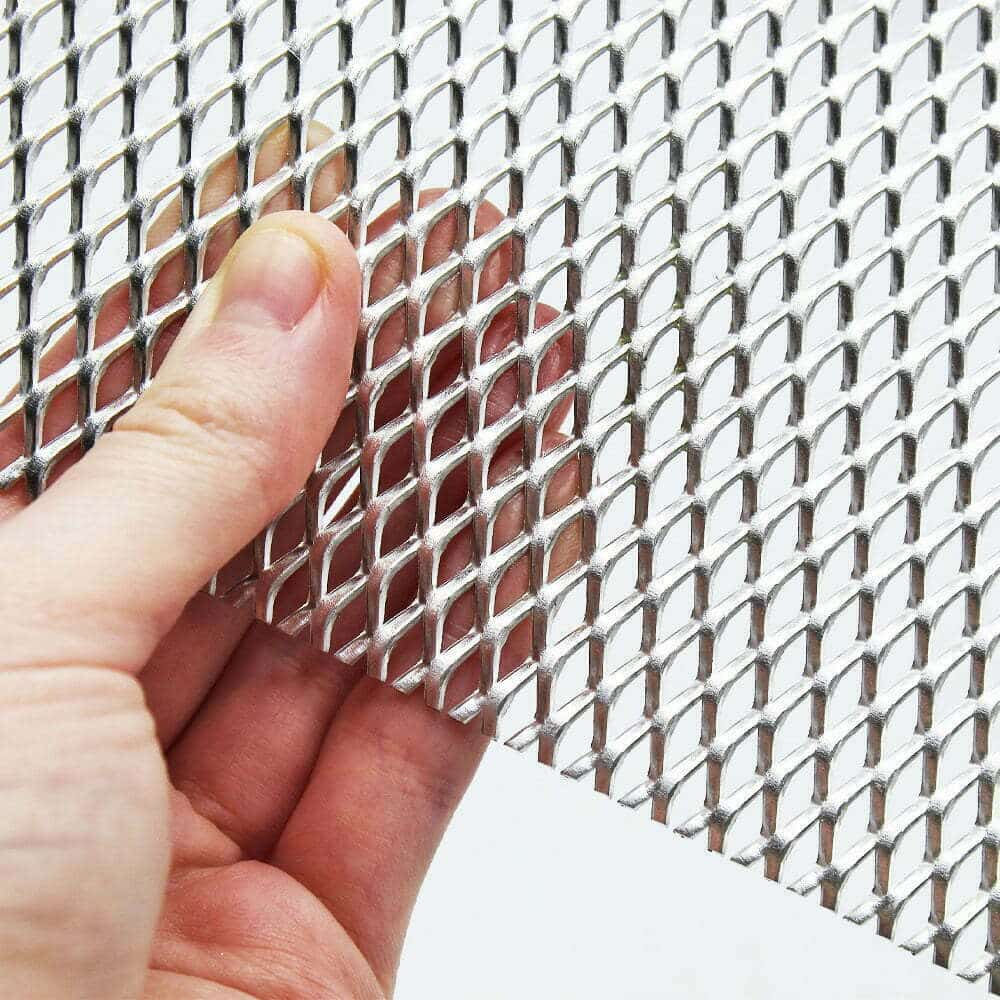

Perforated or Expanded steel or aluminium, expanded aluminium mesh can be lighter than plywood or plastic

And they would be free draining.

Load Restraint

Whichever dimensions, configurations, and construction materials are selected, loads have to be secured to stop them falling out when the vehicle is moving.

Lashing points and D Rings are the cheapest way to do this, simply screwed, bolted or bonded to the load bed or frame,

These can be used with ratchet straps, cordage, canvas covers, and cargo nets.

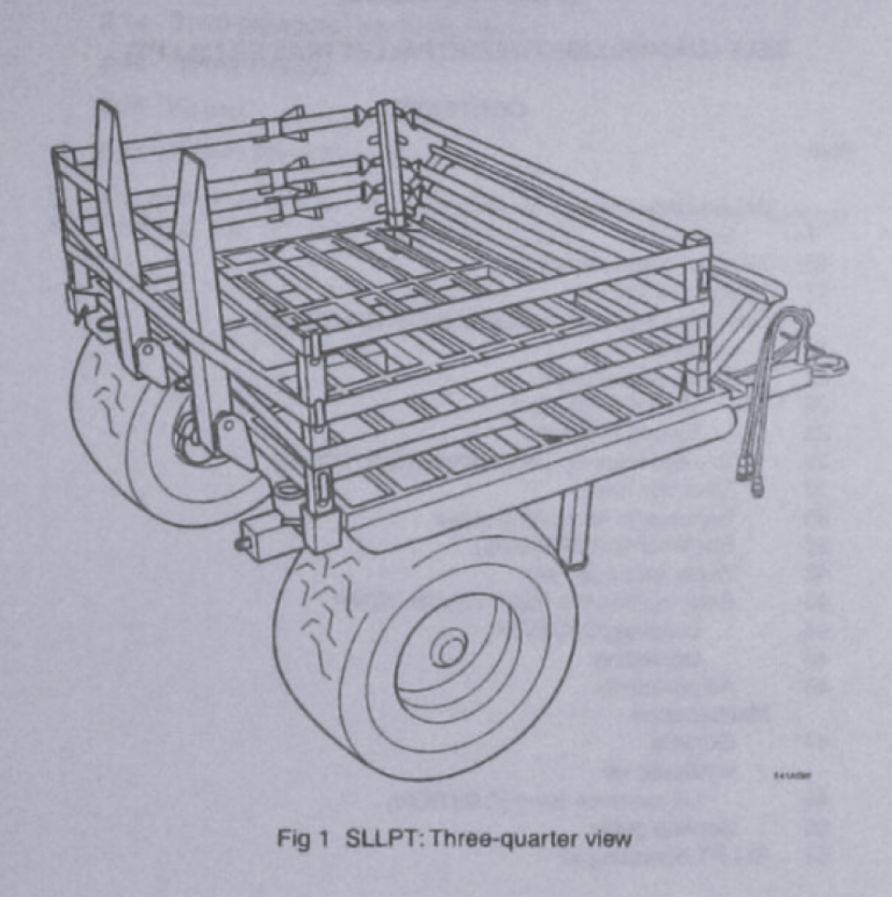

A flat bed design can also be easily fitted with restraining sides. The image below shows a ‘drop in’ design approach, the restraints simply fit into receptacles on the frame and are secured with split pins.

This approach could also work with outboard wheel configurations to extend load carriage volume.

Tubular, or expanded mesh over a framework, work equally well, although the tubular design is perhaps a little easier to fix straps to.

More conventional drop side and extension systems could also be used, none of these are unusual.

Another option could be to fit the frame or body with a rail system, allowing fixtures to be moved and secured at any point.

Extruded aluminium profile such as Bosch Rexroth (and its numerous copies) would provide top, side, and bottom securing options, suitable for 10 mm captive fixings, at the same time as potentially providing the structural members.

This would be flexible and lightweight, but it might not be ‘squaddy proof’ and suitable for use in muddy conditions.

Aluminium extrusions can also be used to create demountable risers

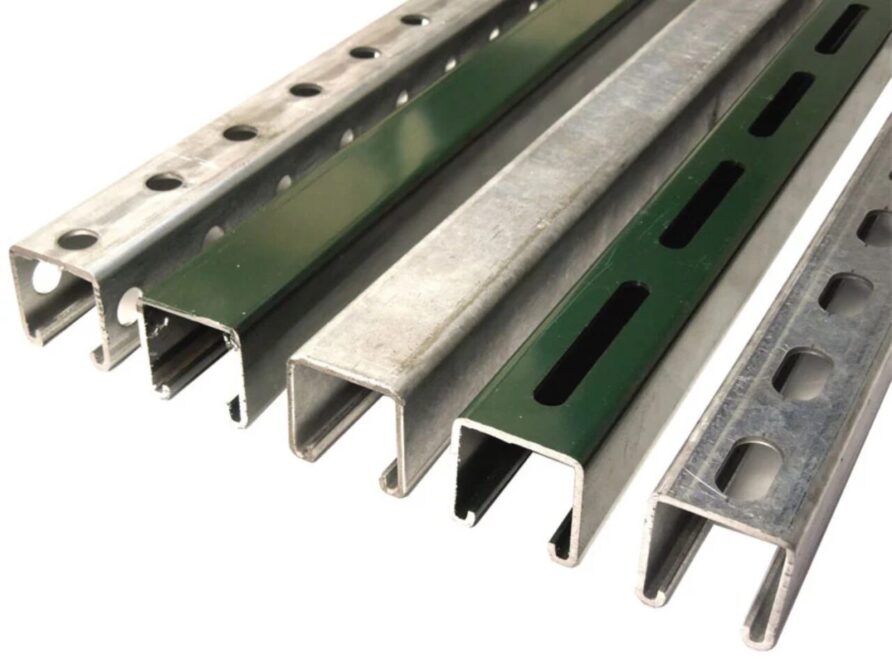

At the other end of the cost and robustness scale, Atkore Unistrut (and also, its numerous copies), could be bolted or welded onto the frame top and sides, or it could even form the frame itself.

Galvanised steel, stainless steel or powder coated, slotted or plan, and in different sizes.

Unistrut would allow fixtures and securing rings, clips, brackets, and lifting eyes to be easily affixed using spring nuts (zebs), 10 mm bolts, and a 17 mm spanner, or other fixings.

Although not a trailer, the image above shows something similar in use on a pickup truck.

Cargo rails used for trucks would be another popular option, there are two main designs commonly in use, the 1805/1806 and E-Track (shown below)

E-Track can be retrofitted by simply screwing into a bed floor or sides, and fittings are widely available.

The Polaris trailer shown in the image below uses E Track components as part of the load bed sides.

Captive tracks, commonly used for securing wheelchairs and vehicle seats, provides another option.

Supacat use rail systems from Koller Engineering on the HMT family of vehicles, so there would be natural re-use. Although these rail systems have origins in the disabled mobility sector, they have been rigorously tested and assured against significant impact loads for wheelchairs and seats.

Rail systems could also be fitted into fixed or drop sides.

A Koller Engineering floor system with integrated load-securing fixture rails would provide even more options,

Tool-holders shown in the image below would complement rail systems.

Finally, Modular Lightweight Load-carrying Equipment (Molle), and derivative, panels could be fixed to multiple trailer locations, and are widely available.

And these could, in turn, also be fitted with tool and Rotopax holders, they are incredibly versatile.

The point of a trailer is to carry cargo, any combination of the approaches described above would contribute to effectiveness, ease of use, and efficiency.

Additional Mobility Options

A simple hydraulic Robson Drive is often used on smaller forestry trailers and could be used on a larger ATV trailer.

In the video below, you can see how they work.

They obviously need a hydraulic power pack and associated hoses/control systems so they would only be worth investing in for larger and heavier trailers, or where there were specific mobility requirements.

With an increasing focus in the High North, it would also be worthwhile to have the ability to replace wheels with skis, or fit over-skis. For skis, the simplest of options is to just attach them to the wheels of the trailer, it is as simple as that, as this video from Iron Baltic shows.

On snow, specialist ski trailers can significantly improve load carriage.

Helicopter underslung load and pontoon attachment points (like the Pac Rat trailer from the USA) would be useful additions.

For commonality, those pontoons could be from the in-service Infantry Assault Bridge.

Casualty Carriage

Specialist rescue trailer are available, the ATR Trailer from All Terrain Res-Q in the US for example.

The trailer folds for easy transport, so could be optimised for CDS compatibility.

Although not strictly a trailer, LV-TEH in Latvia also makes a folding rack that can be used to secure a casualty, not sure how well though!

But for this application, casualty carriage would ideally be done using the same trailer as for other uses, as per the in-service Logic trailers in the image below.

Another example might be a flat load bed trailer, as the image below.

Tipping Load Beds and Pallet Carriage

With a quad ATV, a tipping trailer might also be useful for some specialist users, and for quickly dropping off stores, without manual handling.

However, it adds complexity for what should be a simple piece of equipment.

Another niche capability is pallet handling.

If we take the ability to lift a single pallet as the baseline, and we don’t want complex mechanical, electrical, or hydraulic arrangements, a simple forklift trailer can be used.

Something like in the video below for ATVs and quad bikes.

This is not dissimilar to the Supacat ATMP flipit’ trailer, although this had a higher load capacity than would be required of a quad bike ATV version.

The maximum payload for the ‘ was 1,400 kg, and it could also be converted to carry three stretchers. Demountable corner posts could also be used to form sides for loose loads, with ratchet straps used to secure the load, and a water carriage pack turned the trailer into a water bowser.

Pallet bins or boxes could be used for loose items, and not even demounted.

Orchard bin trailers use tilting load beds, chain drives, and either PTO-driven hydraulic pumps or a hydraulic take-off from the tractor unit to energise chain drives and tilting mechanisms to quickly load and unload the bins. Orchard bins are pallet boxes by another name.

A simple bin trailer is shown below, the trailer is reversed onto the pallet, secured and then the vehicle drives away.

Pallet boxes are available in various sizes, and with lids, drain plugs, dividers and in various colours (thankfully). Disposable liners are used to transport liquids. The US Army used a similar design a few years ago for air despatch, called the Lifeliner CUBE.

By utilising the standard pallet footprint, different types of load can be carried and quickly deployed by relatively small vehicles

Imagine a small UGV dropped off by an ATV, a quad pack of VLS ATGW, a non-explosive means of entry tool kit for assault pioneers in an urban setting, or just a collection of defence stores, the possibilities are endless.

Weapons and Personnel Carriage

The majority of the designs are above are relatively compact, and light enough to be towed by small quad ATVs.

However, in the previous post I highlighted a collection of larger vehicle options that, in turn, could be used with larger trailers.

The LV-TEH Combat Support Platform from Latvia is an example of a trailer that would benefit from a larger ATV.

Originally intended as a towed mobility platform for a 6×6 ATV and for weapons like the 12.7 mm HMG and 40 mm GMG, they have evolved the concept to include several ‘modules’

All interesting.

In addition to those above is a personnel carrier version, equipped with four seats.

These would sit across the ATV/UTV space, but included here for completeness.

The next and last post in this series will summarise, and suggest a few paths forward.