A proposal for the UK MoD, DFiD and industry to generate a port opening and augmentation capability to be used for defence engagement, military operation enabling and disaster relief purposes.

I have written on the subject of port opening, repair and enablement in both a defence and disaster relief context a number of times, with the longest at the links below.

Opening the Port of Cherbourg, 1944

Over the Shore Logistics at San Carlos and Beyond, 1982

Disaster Relief following the Haiti Earthquake, 2010

Opening the Port of Umm Qasr, 2003

In doing so, and observing more recent deployment and disaster relief operations, I believe that we probably should devote more resources to a port survey, repair, augmentation and operations than we do. It is also an area where, despite an almost unlimited potential for spending money, we can gain usable uplifts in capability for relatively modest sums.

Joint Port Opening Capability in Context

Disaster Relief and Climate Change

With seemingly an increase in global instability and a definite increase in extreme weather events, establishing and maintaining a broad set of response capabilities will align with a number of national objectives and resultant strategies, especially as described by the Integrated Review.

It is clear that the UK sees ‘stability’ as a significant part of the remit of Overseas Development Assistance (ODA) and that funding will follow. It also demonstrates that it is well established; organisationally, doctrinally and financially. With the Modernising Defence Programme, new National Security Objectives and the emergent Fusion Doctrine, there is a conscious effort to provide even greater alignment and direction across departments, or joined-up government in the old fashioned vernacular. A less well-known aspect of the recent changes to the UK’s strategic outlook has been work completed on Cross Government Funds, if there is cash for proposal, it may well find its roots in this work. Click here to read more.

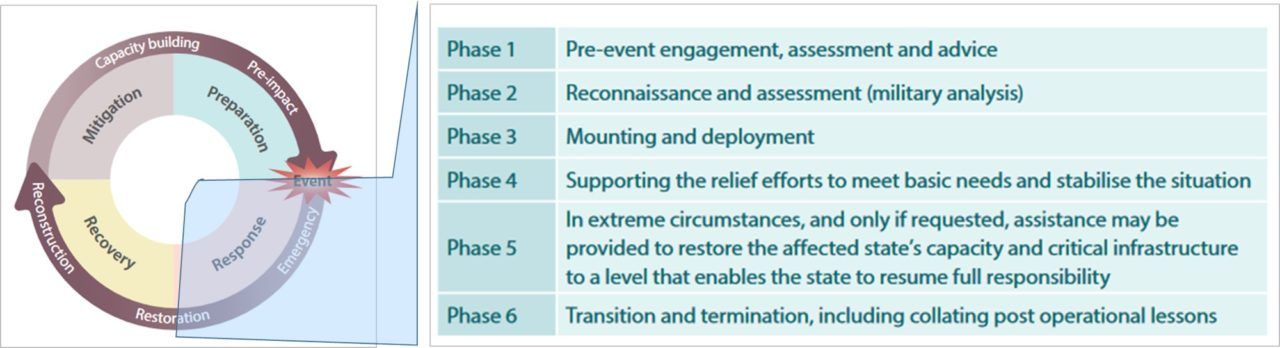

We can, therefore, place the requirement for a port repair and operating capability in the wider context of the Governments strategic approach to stability but dropping down to the operational level we should have another look at the disaster response doctrine publications published by the MoD. Disaster relief operations (JDP 3-52) provides guidance for planning and conducting military support to humanitarian relief efforts overseas.

This text is particularly important;

UN guidelines, commonly known as the Oslo Guidelines state that civilian assets are to be preferred over the military when providing humanitarian assistance; this is linked to the principle of last resort. Therefore, DFID will normally only request military assistance when there is an acknowledged gap between humanitarian needs and the civilian resources to meet them, and where the response is acceptable to the local population and in support of the wider relief effort. The military response must have a comparative advantage over civilian options; such advantage may be: speed of reaction, the scale of effort or availability of specific resources.

And it is here where there is space for a joint capability set, owned by all three services and the FCO.

It also describes the generic phases of disaster management and establishes the military response element to the lower right quartile of the cycle, perhaps reasonably.

As fusion doctrine matures, potentially, these distinctions and dividing lines will blur.

[the_ad id=”53392″]

Expeditionary Operations

In a conventional defence amphibious operation, the amphibious force would land on a beach, then create a lodgement area where materials could be gradually built up and additional forces landed. Once sufficient mass had been achieved, the combined force would push inland towards the main objective with follow on stores and forces reinforcing the initial landing force.

The advent of the helicopter meant that the beach could be bypassed to some extent but it was always acknowledged that for any operation at scale there was no avoiding having to create a lodgement area and transit point for sustainment stores and follow on forces. With the advent of long-range precision weapons having a lodgement area close to the final objective was seen as too risky and the various sea basing and other ‘ship to objective manoeuvre’ concepts evolved to counter this threat by ignoring the beach, projecting and sustaining the manoeuvre force to its inland objective directly from a seabase. The seabase would be a collection of logistic support vessels anchored far enough offshore to be relatively safe. This is a logical counter to anti-access technologies such as precision weapons and advanced mines but it places a great deal of emphasis on aircraft and other extremely expensive equipment.

With the seabase established safely fifty or sixty nautical miles offshore, the cycle time between it and any objective is critically dependant on the speed of the connectors. Fine if those connectors are helicopters but for traditional landing craft and pontoons plodding along at 5 to 10 knots, the buildup of force density and sustainment stores becomes frustratingly and dangerously slow. This then led to thinking about high-speed connectors like hovercraft and fast landing craft using novel hull forms and propulsion systems, adding yet more cost and support requirements. Those fast connectors then needed large safe lanes, free from mines and surface threats, this added yet more cost and capability to achieve.

Our doctrine had developed to avoid opposed landings many years ago in any case, so the general approach would have been to land where the enemy is not, gets ashore fast enough and in enough mass to avoid falling victim to an enemy counter-attack, and then secure a port from the land side. This theory rests on the port in question is close enough to manoeuvre to from the beach lodgement area, heavy forces that can invest a large port, generally speaking, are logistics heavy and somewhat difficult to move across large distances, especially if being logistically supported from the seabase across a beach.

For the UK, this was simply unsustainable, which might explain why 3 Commando Brigade looks very different now and the Future Commando Force emphasises raiding, not putting a force ashore to provide a pathway for a larger mechanised force from the British Army. With the Royal Marines becoming a raiding force, one of the LSD(A) sold and another about to be converted to support the emerging maritime strike groups, it looks very much like the UK is out of the amphibious game.

By default, this then means any expeditionary theatre entry needs ports.

The Changing Coastal Environment

The MoD’s Development, Concepts and Doctrine Centre (DCDC) regularly publish a document called Global Strategic Trends which describes the context for defence and security out to 2045.

It is available from this link

https://www.gov.uk/government/publications/global-strategic-trends-out-to-2045

Global Strategic Trends is an excellent document that should be used to inform capability generation.

One of its themes is that of urbanisation.

With 70% of the global population likely to live in cities by 2045, urbanisation will be a particularly important theme in developing countries. Urbanisation is likely to enhance economic and social development, but – without mitigation measures – may also lead to pressure on infrastructure (and the environment) which could contribute to social tensions within the urban population. Urbanisation and the effects of climate change are likely to result in an increase in the magnitude of humanitarian crises, particularly since the majority of urban areas will almost certainly be either on, or near the coast, making these cities vulnerable.

The United Nations also publish information on urbanisation.

http://esa.un.org/unpd/wup/Highlights/WUP2014-Highlights.pdf

Migration to coastal regions is common in both developed and developing nations and population density is observed being higher in coastal cities than in other areas. If the current trends in population growth, urbanisation and migration continue over three-quarters of the world’s population will be living within 150km of the coast.

By 2030 it is predicted that the coastline between Sao Paulo and Rio de Janeiro will be a single urban sprawl housing 40 million people. In South-East Asia 75% of all cities with a population in excess of a 2.5million are on the coast. Closer to home, the Mediterranean basin has one of the highest population densities anywhere. The Sustainability Observatory reports that a quarter of Spain’s seafront has been extensively urbanised.

Population growth results in an increased level of coastal land development; dredging, land reclamation, pipelines, housing, hotels, port development, marinas, storage facilities, fisheries and mines (mineral, not explosive).

Coastal land development increases the economic value of that land and in turn, increases the demand for tide and storm protection, erosion control, and as a result, the coastline becomes increasingly concreted. For amphibious operations, the problem becomes less one of getting onto the beach and more of one of getting off it.

In the developing world, the lack of effective governance and land management means land development generally wins over beach preservation. Where beaches, coral reefs and mangrove swamps are retained it is because they are valuable to local economies, but they will be under constant pressure.

If the developing world follows the same trajectory as the developed world, shorelines will change dramatically over the next several decades, perhaps even more so as megacities in Africa, South America, Asia and the Middle East grow at faster rates than those in the West.

The world’s population is increasingly moving to cities and those cities are increasingly situated on coastlines. None of this necessarily means that ALL shorelines are changing, or that ALL shorelines of interest are changing. But it does mean that it is an issue we should be making plans for.

Ports

If the coastal landscape is changing because of economic activity and increasing urban populations, so are ports. Increasing population and globalisation means increasing trade, increasing trade means increasing shipping activity, but how does affect ports?

The short answer is, in very specific ways.

For container shipping, larger ships seem to be the trend; New Post Panamax and Malacca Max for example. The demand for efficiency has resulted in greater automation and fewer, but much larger ships.

If we believe that future operations in Africa may be more likely than less, port trends in Africa are important to consider. Here we find that port density compared to the coastline is low and large areas do remain undeveloped. There are many small and medium-sized ports approaching capacity, quality of aids to navigation, machinery availability and dredging consistency also plague many African ports.

Most African nations with a coastline have one or two large container terminals that handle gateway volume and act as transhipment routes for neighbouring landlocked countries. Pure Transhipment Ports together with regional and sub-regional feeder ports are emerging as the standard model. West African terminal growth is ensuring that these large ports can handle the very large 14-18 thousand TEU ships.

The increase in the size of vessels has resulted in ‘cascading’, a process where the largest ships relegate smaller ships (even they are actually very large) to smaller terminals. The infrastructure needed for different types of cargo (bulk, liquids, RORO and containers) has also resulted in port specialisation. Felixstowe for example has no RORO, bulk or liquid cargo facilities whatsoever. Increasingly large and specialist ports act as hubs and more numerous feeder ports collect and distribute on short sea routes.

There are about 500 container ports worldwide able to handle more than a thousand TEU’s per year with the largest able to handle container capacity in the millions per year but it is noteworthy that less than 20% of worldwide ports handle containers in any meaningful manner despite the high penetration of containerised traffic.

Ship draught and port dredged depth differences have a significant impact on logistics operations. One survey found that in order to access ports in Saudi Arabia during Operation Desert Shield, the average utilisation of US sealift ships was a mere 23% of their maximum capacity, the implications of which should be obvious to all. During Operation Restore Hope in Somalia, the first three US prepositioning ships to arrive at Mogadishu had to turn around and go elsewhere or back to Diego Garcia because the port environment was simply too shallow.

What all this means is that smaller ports are increasingly being developed alongside their mega port contemporaries. The smaller coastal ports (and inland ports) tend to be multi-purpose and in order to meet the demands that result from consolidation in mega ports they are both being developed and becoming increasingly numerous.

Small to medium size port infrastructure is increasingly inaccessible to our traditional large cargo vessels but easily accessible by increasingly larger feeder vessels.

The trend, therefore, seems to be fewer larger ports for mega container ships which drives the cascade effect, the emergence of sub-regional feeder ports, port specialisation and a general improvement of ports across the full spectrum of sizes.

Defining a Joint Port Opening Requirement

If there are conclusions from above, they are fairly simple; coastlines are being increasingly developed and main ports are increasingly large and specialised but smaller ports are increasingly numerous, and more general purpose. In planning for future expeditionary or disaster relief operations, neither of these can be ignored, nor can we ignore the changing role of the Royal Marines.

With the British Army increasingly becoming a wheeled force (as it introduces Boxer and eventually MRV-P), the ability to transit increasingly larger distances from a port of entry leads to decreasing reliance on going over the beach. Just as well that beaches with favourable terrain are becoming increasingly fewer and easy to predict. With proliferating long-range precision munitions, persistent surveillance and pervasive media connectivity, the distance from a relatively safe beach and objective become increasingly larger. One then arrives at a conclusion that extending the distance between entry point and objective, together with increasingly inaccessible coastline and increasingly common smaller ports, means that going over a beach at a safe distance is more trouble than going into a small port at the same safe distance.

We should concentrate on ports, not amphibious landings.

This also means that RORO shipping and civilian charters become more central to the deployment options for the British Army.

The requirement comes in three parts;

Rapid Port Survey; a centre of excellence for port survey, design, programme management and contract delivery, including a rapid response survey capability. This rapid response survey capability should be held at readiness and able to utilise the UK’s C-17 or A400M fleet of aircraft. We already have some elements of this in place, to achieve the full capability would only require a modest investment.

Click here to read

Port Clearance, Repair and Operation; a means by which existing ports can be cleared of debris or mines, repaired to a level that can support in service and civilian shipping, and an ability to operate that port.

Click here to read

Port Augmentation and Operations; A means by which existing ports or urbanised shorelines can be augmented to enable in-service and civilian shipping access. This may be unachievable as it would likely require significant capital spending but is presented as an option.

Click here to read

Table of Contents

[adinserter block=”2″]

[adinserter block=”1″]

Change Status

| Change Date | Change Record |

| 30/05/2017 | initial issue |

| 26/07/2021 | Refresh and change in page structure |

Discover more from Think Defence

Subscribe to get the latest posts to your email.

I commend the author for a well-researched and informative piece. Don’t be too self-depreciating, you’re clearly someone with expertise! The article builds upon the Conservative proposal to redefine how we utilise the ODA budget, incorporating and formalising more of what the MOD can deliver as part of a joint enterprise. I fully support that. Delivering a X-Govt (MOD-DFID) Port Opening Capability is a good example of where those interest could align. The two departments could/should certainly come together to better codify a range of likely tasks and roles and responsibilities once the ODA budget is more broadly defined. When it comes to ways and means being packaged and held at specific readiness I’m a little less convinced that the ambition will ever be realised. For the MOD’s part we pretty much still retain a full spectrum Port Enabling Capability, with ends defined as being able to project over a bear beach, through austere ports to off loading at a well-found one. We have survey capability (STRE), ship-to-shore capability, EOD and dive experts, plant and lighterage. What’s new, and not covered in your article, is that we have harnessed a wider array of commercial options with the requirement and partnership we have with Solent Gateway Ltd. There is a Whole Force aspect to this new contract that enables us to supplement existing military means. We have plenty of precedent of being able to work as a supporting department to DFID (and their funding) when required, bringing the all-important Port Enabling capability to bear: Op PANLAKE (Haiti) and Op ZEST (Tristan da Cunha). We can already support the STRIKE concept in the manner you describe. Achieving Speed of Assembly (Port Enabling – Open, Activate, Sustain) is germane to Deterrence and vital ground for Defence. The MOD’s focus must be here and thus we are unlikely to have sufficient extra capacity to act as an insurance policy for others or triple hat it.

Thanks Hutch, great feedback and very kind.

PS, similar long form article on D Day, San Carlos, Umm Qasr and Haiti at these links;

They all informed this one

https://www.thinkdefence.co.uk/al-faw-operation-open-iraqi-port-umm-qasr/

https://www.thinkdefence.co.uk/military-humanitarian-assistance-disaster-response-hadr-haiti-2010/

https://www.thinkdefence.co.uk/shore-logistics-san-carlos-beyond/

https://www.thinkdefence.co.uk/shore-logistics-d-day-beyond/

I didn’t know about the Solent Gateway relationship and it is great to hear about it.

As much as anything, this type of proposal is thinking out aloud and asking a few questions rather than a solid business case. As I said, we have an embarrassment of riches in this area across defence, the MoD and civilian sector, so this was as much about harnessing that and pulling it together as anything else. The background to a changing shore environment, Strike Brigade deployments and contributing to the Building Stability Overseas agenda is there to provide a context for my flimsy justification for ‘doing more’

I think we should do more in this area because, well, I just think we should!

I found this memoire by a Sapper officer of 82 Port Regt AER regarding Op MUSKETEER (Suez 1956) http://www.patmckeown.co.uk/assets/docs/the-suez-campaign-of-1956.pdf mainly personal but describes quay clearing and trying to get cranes working.

Congratulations on a comprehensive and detailed article. However… …I did expect more in the way of the traditional TD ‘ISO container porn’.

Thanks TD, looking at all the pieces, from March 12 through to this one, I guess it is time to roll up the sleeves and start reading. Any more installments to await? Are you planning to merge it all into an “e-book”?

I agree with Hutch’s ” can already support the STRIKE concept in the manner you describe. Achieving Speed of Assembly (Port Enabling – Open, Activate, Sustain) is germane to Deterrence and vital ground for Defence. The MOD’s focus must be here” and that POV is what gives me an interest for also the more technical aspects… of which I am looking forward to finding a good dose.